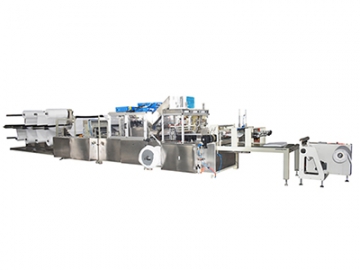

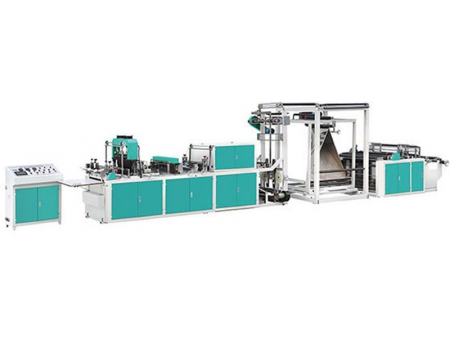

Fully Automatic Non-woven Bag Making Machine for 6 Types of Bag with Handle, WFB-AT600

Bag Machine/ Bag Maker/ Bag Production Line

Introduction

This fully automatic non-woven bag making machine is designed to produce 6 types of bags and features an automatic bonding handle. This highly automated machine is incredibly efficient, you can change the type of bag produced and size by simply switching materials. The equipment reduces waste and increases precision compared to similar products.

Applied Materials

This machine is suitable for BOPP woven fabric, regeneration non-woven and lamination non-woven fabric material.

Material thickness range: 20-120gsm.

Advantages

1. One machine can make six types of bags.

2. Less waste, high speed, high production output.

3. Adjust speed, size by computer.

| Model | WFB-AT600 |

| Max. Bag Making Width | 600mm |

| Bag Making Thickness Range | 20-100g |

| Max. Bag Making Length | 700mm |

| Production Speed | 40-90pcs/min |

| Total Power | 16kw |

| Machine Weight | 3.5t |

| Overall Demensions | 12000*2000*2100mm |

-

D-cut bag

Raw material roll (printing is inside) -- fold mouth of bag -- fold in half -- D-cut punching -- ultrasonic seal side -- cut -- finish -

Flat bag

Raw material roll (printing is inside) -- fold mouth of bag -- fold in half -- make handle -- ultrasonic seal side -- cut -- finish -

T-shirt bag

Raw material roll (printing is inside) -- fold mouth of bag -- fold in half -- fold both sides (T-shirt bag mould) -- ultrasonic seal side -- cut -- automatic T-cut punching -- finish

-

Zipper bag

Two raw material rolls (both PP, printing is inside) -- fold mouth or bottom of bag -- sealing PP zipper -- D-cut punching -- ultrasonic seal side -- cut -- finish -

Box bag

Raw material roll (printing is outside) -- fold mouth of bag -- fold in half -- line pressing -- fold the bottom and seal(triangle bottom sealing) -- make handle -- triangle bottom punching of bag -- ultrasonic seal side -- cut -- finish -

Draw string bag

Raw material roll(printing is inside) -- put string -- fold mouth of bag -- fold in half -- ultrasonic seal side -- cut -- finish

FAQ

Q: Can you design machines according to our request?

A: Of course. You can provide your size, color, then we will create a design for you.

Q: Do you provide after-sale service?

A: Sure, it is a must.

Q: How about your machines' quality?

A: Our machines are famous for high quality and reasonable price, we are sure you will be satisfied with them.