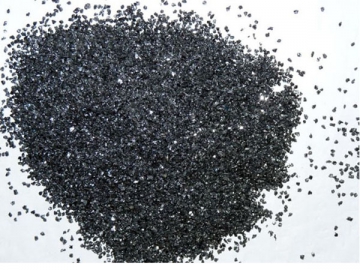

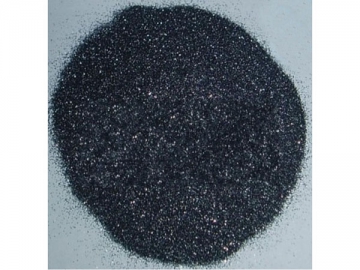

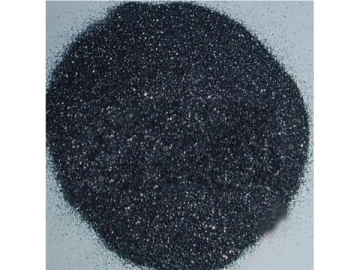

Black Silicon Carbide

BlackSilicon Carbide

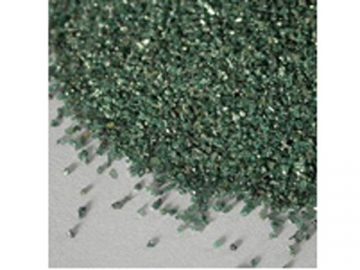

Blacksilicon carbide, a kind of granular abrasive material in black color, exhibitsgood electrical and thermal conductivity, desirable traits in many applicablesituations. It is borne fromthe combination of quartz sand and petroleum coke, processed via a high temperatureresistance furnace. The resultinghardness is rated higher than fused alumina but lower than syntheticdiamond. Brittle and sharp, thissubstance is capable of mechanical intensity superior to that of the fusedalumina. It is commonly utilized for the processing and grinding ofglass, ceramics, stone, cast iron, alloy, titanium alloy, etc. Competitively priced, it may also be used asa refractory material.

Specifications

| Chemical composition ( %) (GB/T2480-1996) | |||

| Grit | SiC | F.C. | Fe 2 O 3 |

| F12~F90 | ≥ 98.50 | < 0.20 | ≤ 0.60 |

| F100~F150 | ≥ 98.00 | < 0.30 | ≤ 0.80 |

| F180~F220 | ≥ 97.00 | < 0.30 | ≤ 1.20 |

| F230~F400 | ≥ 96.00 | < 0.40 | ≤ 1.20 |

| F500~F800 | ≥ 95.00 | < 0.40 | ≤ 1.20 |

| F1000~F1200 | ≥ 93.00 | < 0.50 | ≤ 1.20 |

| P12~P90 | ≥ 98.50 | < 0.20 | ≤ 0.60 |

| P100~P150 | ≥ 98.00 | < 0.30 | ≤ 0.80 |

| P180~P220 | ≥ 97.00 | < 0.360 | ≤ 1.20 |

| P230~P500 | ≥ 96.00 | < 0.40 | ≤ 1.20 |

| P600~P1500 | ≥ 95.00 | < 0.40 | ≤ 1.20 |

| P2000~P2500 | ≥ 93.00 | < 0.50 | ≤ 1.20 |

| Note: Special requirements on chemical compositions can be satisfied through further discussion. | |||

The silicon carbide can be made into bondedabrasive and coated abrasive. The bonded abrasive comes with a grain sizeranging between F12 and F1200. The coated abrasive grain size ranges from # 8 to #8000. The coated abrasive comes with finest grain size of P2500. The finer thegrain size, the lower the silicon content will be. Thus, the material hardnessand strength is varied according to grain size as well. Our products areproduced according to FEPA and JIS Standards.