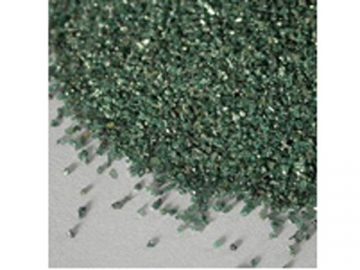

Green Silicon Carbide

GreenSilicon Carbide

Ourgreen silicon carbide is manufactured in strict conformation with FEPA and JISstandards. A product of highpurity materials and salt additives, the carbide is forged through a resistancefurnace at an approximate temperature of

Specifications

| Chemical composition(GB/T2480-1996) | |||

| Grit | SiC | F.C. | Fe2O3 |

| F20~F90 | ≥ 99.50 | <0.20 | ≤ 0.20 |

| F100~F150 | ≥ 98.50 | <0.25 | ≤ 0.50 |

| F180~F220 | ≥ 97.50 | <0.25 | ≤ 0.70 |

| F230~F400 | ≥ 97.00 | <0.30 | ≤ 0.70 |

| F500~F800 | ≥ 95.50 | <0.40 | ≤ 0.70 |

| F1000~F1200 | ≥ 94.00 | <0.50 | ≤ 0.70 |

| P12~P90 | ≥ 99.00 | <0.20 | ≤ 0.20 |

| P100~P150 | ≥ 98.50 | <0.25 | ≤ 0.50 |

| P180~P220 | ≥ 97.50 | <0.25 | ≤ 0.70 |

| P240~P1000 | ≥ 97.00 | <0.30 | ≤ 0.70 |

| P1200~P2500 | ≥ 95.50 | <0.40 | ≤ 0.70 |

| Special requirements on chemical compositions can be satisfied through further discussion | |||

Thisproduct can be categorized into the coating abrasive and the abrasive. The coating abrasive grain size ranges between P12 andP2500. The bonded abrasive is moreversatile and has various size ranges, includingthe F20 to F90 range and the F1000 to F1200 range. The coarser the grains, the more siliconcarbide it contains. For instance, the grain size ranging between F20 and F90contains 99.5% silicon carbide. This imbues the abrasive with extreme hardnessand it can be used for cutting or grinding highly hard materials.