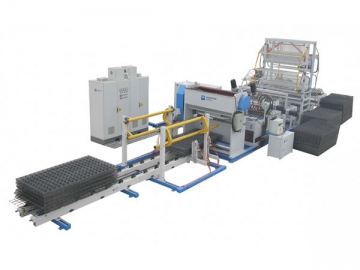

Fully Automatic Reinforcing Mesh Production Line II

Engineering Mesh Machine / Wire Mesh Welder / Construction Mesh Machine

Features of the Fully Automatic Reinforcing Mesh Production Line II

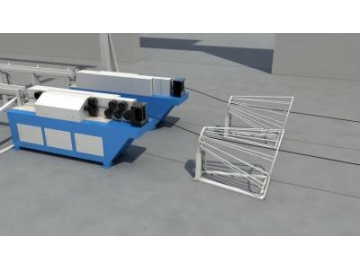

1. Both line and cross wires are fed from coils which are straightened, cut and fed online automatically.

2. The welding electrodes and transformers are equipped with a water-cooling system to prolong the service life of the wire mesh machine.

3. The welding system is synchronously controlled and the welding transformers can work simultaneously or separately.

4. The main structure of welding machine is motor driven and spring weighted to minimize operating costs.

5. Mesh materials include, hot-rolled ribbed bar, cold-rolled ribbed bar, hot-rolled plain bar, cold-rolled plain bar, etc.

6. Can be equipped with turnover, dropping and automatic packaging devices.

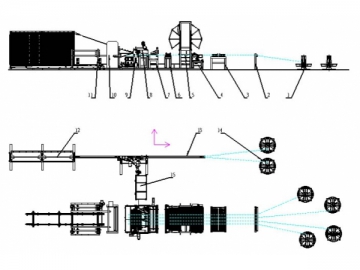

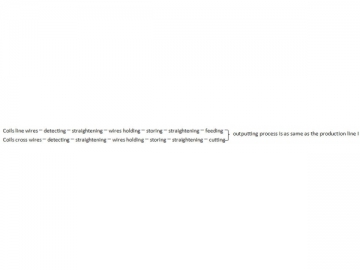

Technological processes of the Fully Automatic Reinforcing Mesh Production Line II Technical Parameters of Fully Automatic Reinforcing Mesh Production Line II

Technical Parameters of Fully Automatic Reinforcing Mesh Production Line II | Model | GWCD2500 (3-8) | GWCD1600 (3-8) |

| Quantity of welding spot | 24 | 16 |

| Width of mesh | ≤2500 mm | ≤1600 mm |

| Rebar diameter | 3-8 mm | 3-8 mm |

| Length of mesh | ≥1 m | ≥1 m |

| Transverse bar spacing | ≥50mm | ≥50mm |

| Longitudinal bar spacing | 50-200 mm | 50-200 mm |

| Power | 500 KVA | 400 KVA |

| Welding speed | 80-100t/min | 80-100t/min |

| Control system | PLC | PLC |

Applications

This wire mesh machine produces a variety of mesh products that are utilized to construct large-scale structures such as high-rises and bridges.