Cooling Gel Patch Packaging Machine

This cooling gel patch packaging machine is designed for the production and packaging of a range of cooling products, such as antipyretic patches, ice patches, cooling gel patches, cold compress patches, and more.

Our production line comprises four machines: a gel mixer, a feeder, a coating slicer, and a four-side patch packaging machine.

- Model: PPD-60L

- Diameter: 420 mm×290mm

- Vacuum degree: -0.098 Mpa

- Structure: Cantilever

- Rotating speed: 0-130 revolutions per minute, 0-267 rotations per minute

- Power: 4kw/4P

- Power supply: 380 V, 3 ph, 50hz

The gel mixer is made up of an array of components, including a base, a beam, an upright column, a kettle cover, a kettle body, a transmission and an electric control system. Combining the features of a planetary machine and a powerful dispersing machine, it utilizes a unique mixing mechanism where the dispersing shaft and the mixing paddle respectively perform a planetary motion of both revolution and rotation, whose speed can be adjusted with frequency conversion. This allows the material to execute complex motion under powerful shearing, kneading and dispersing. Moreover, the inner cylinder of the kettle has been fitted with an automatic wall and bottom scraping device to scrape off materials stuck to the kettle wall, attaining both the absence of dead points and efficient mixing - making it an ideal vacuum emulsification tool and stirring equipment for hydrogel products.

- Model: PPD-60

- Oil tank capacity: 40 L

- Control mode: Electric hydraulic control, with the option of manual or electric operation.

- Platen stroke: 800mm

- Platen structure: Inclined cone shape

- Sealing between platen and barrel: Circular neoprene rubber seal

- Discharge method: Pressure cover discharge

- Discharge caliber: 76mm

- Power supply voltage: 380V 50 Hz

- Total power: 5.5kw

- Hydraulic pressure: 6.3-10MPa

This feeder is equipped with an emergency stop switch, which controls the oil pump motor with the main power switch. The lifting stroke of the solenoid valve is controllable either manually or automatically.

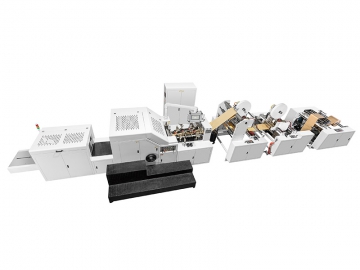

- Model: PPD-CM 500

- Product finish size: 120x50mm, 110x40mm, 100x140mm, and 90x40mm

- Coating width: 500 mm

- Non-woven fabrics and membrane coiled material: width up to 350mm, Φ≤400mm, on paper cores with an inner diameter of 76.2 mm

- Processing capacity: 0-400 PCs/min

- Total power: 220V, 50 Hz, 4 kW

- Air consumption: ≥30m3/H (self-provided)

- Pressure: 0.6-0.8 Mpa

This new type of coating slicer is ideal for producing gel patches, antipyretic patches, cold compress patches, crystal mask patches, nasal patches, eye patches, and other medicinal cataplasm coating slices.

Process flowLoading non-woven fabric coiled material and embossed film coiled material, introducing hydrogel into glue cylinder → coating → combining→ longitudinal cutting → transverse cutting → outputting finished product → automatic splicing → conveying

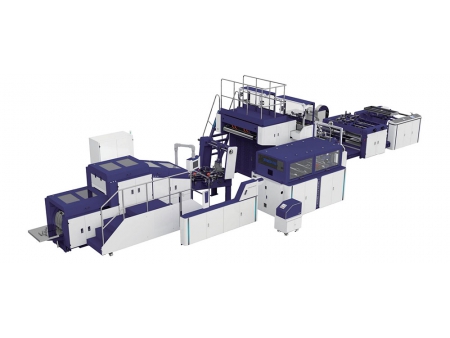

- Patch size: length 90-200 mm × width 60-150 mm

- Processing capacity: 80-160 patches/min

- Packaging film materials: Paper-aluminum-plastic, pure aluminum, aluminized, pearlescent film, coated paper, etc., Φ ≤ 350mm

- Raw materials: cold compress, antipyretic patch and plaster, warm pad, eye patch, and nasal patch.

- Voltage: 220V 50Hz

- Power: motor power 2.2KW, heating power 3.3KW

This four-side sealing packaging machine is designed for packaging a variety of medicinal products and medical items, such as cooling gel, antipyretic paste, ice paste, cooling paste, and cold compress paste. It also finds application in the packaging of masks, gloves, eye patches, nose patches, and heating pads.

Process flowManually placing the sheet onto the conveyor belt → putting the product into the patches→ combining → sealing→ cutting off → transporting the packaged product