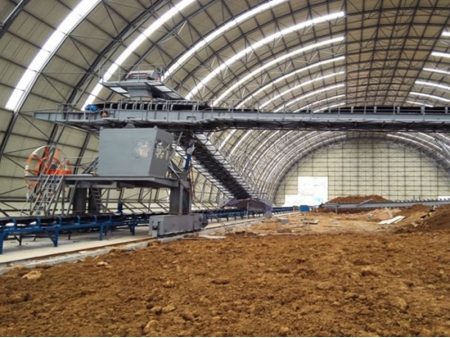

Side Boom Stacker

The radial stacker can work simultaneously in different stockyards. This efficient and large bulk material handling equipment is applicable to stacking cement, coal, metallurgical flour and chemical products. The stockyard system can handle a variety of materials, however, it must be noted that only a single material type can be stored in a single tank.

| Model | Capacity (Max) | Inlet belt width | Rails gauge | Rail type |

| 600t/h | 1000mm | 5m | 43kg/m | |

| 1600t/h , max:1850t/h | 1400mm | 5m | 50 kg/m |

- SINOMALY’s stacker reclaimer is equipped with a boom made using a thick and solid I-beam in order to guarantee the boom strength and increase the bulk material conveyance distance.

- The overall structure of the stockyard should be taken into account during the automatic control design for the stacker reclaimer’s side boom. To be more specific, the stockpile height should be pre-determined to ensure a flexible, efficient material stockpiling and reclaiming throughout the entire stock yard.

- This bulk material handling equipment is outfitted with several control methods, which will ensure flexible bulk material handling in different situations.

- With an easy installation, the side boom stacker can be easily operated by a single employee after a simple training process.

Boom

Welded with a steel I-beam, the boom is equipped with a boom conveyor, tension unit, flow measurement device, slip detector, and anti-deviation device. An adjustable baffle is mounted on the discharge cylinder, the angle and position of which is adjusted to adjust the blanking point.

Travelling mechanism

The travelling mechanism is made up of a triangular gantry and a driving device, which achieves a soft start and delay braking. There is a platform on the lower portion of the triangular gantry, which is used for installation of a luffing hydraulic system.

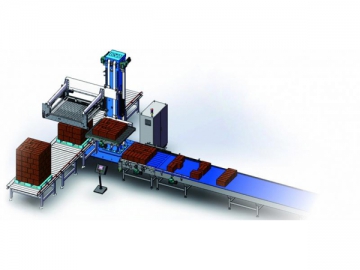

Tripper car

The feed car is used for distributing material into the stockyard, and consists of the discharge hopper, oblique beams, A columns and more.

Hydraulic system

The hydraulic system carries out a vertical up/down (luffing) boom movement.

Cable reel

The cable reel is used for storing power and control cables.

Tripper car

Steel structural support

Operator cabin

The operator cabin is mounted on the steel structural support, and is equipped with an interior PLC system and electrical cabinets.

Boom counterweight

The boom counterweight is used to balance the stacker and keep it from falling over.

There are three operation modes for the side boom stacker reclaimer: automatic control, on-board manual control and side (maintenance) control. Each operation mode is carried out through an alternation switch.

- Automatic control

Under automatic control, the stacking operation is carried out in the on board, central control room. When a central control room is required to automatically control the stacker and reclaimer, the operator needs to only press the operation button on the console, then press the start button. All electrical equipment on the stacker will start according to the predetermined procedures, and the stacker reclaimer will automatically operate. On the operation console, operators can start or stop an entire stock yard system simply by pressing a button. - On-board manual control

During the debugging process or in the event errors occur during automatic control, the operation in the control room simply needs to use the on-board manual control to carry out stacking operations. When manual control is in use, the equipment cannot switch to automatic or side (maintenance) control.