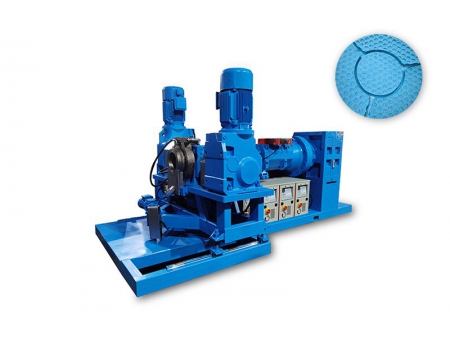

Rubber Ram Strainer, RS Series

Request a Quote

The RS rubber ram strainer can be used on nitrile rubber, butyl rubber, fluorine rubber, silica gel and other rubber materials as well as rubber and plastic mixtures for a filtration accuracy of 200 meshes. This type of filter does not produce heat or scorching during the filtration process and can even be used with an accelerator for higher efficiency. It also features a safety control as well as user-friendly design and simple operation, with its head designed for easy opening and eye-catching tips for clear instruction.

Specification

| Items | Unit | RS150 | RS200 | RS250 | RSH200 | RSH250 |

| Barrel inner diameter | mm | 150 | 200 | 250 | 200 | 250 |

| Total power | KW | 14 | 14 | 17.5 | 17.5 | 17.5 |

| Max. extruding pressure | MPa | 36.8 | 20.7 | 20 | 40 | 36 |

| Max. barrel temperature | oc | 95 | 95 | 95 | 95 | 95 |

| Single feeding volume | kg | 10-15 | 20-30 | 60-70 | 25-35 | 60-70 |

| External dimension (LxWxH) | m | 2.78x1.2x62 | 2.85x1.2x1.64 | 3.97x1.25x1.64 | 3.7x1.35x1.85 | 4.9x1.35x1.85 |

| Weight | t | 2 | 2.17 | 3.2 | 4.1 | 4.5 |

Advantages

- Energy efficiency Low energy consumption compared to screw extruders, with an average power usage of about 7 kWh/hour.

- Efficient Product capacity up to 300-900 kg/hour. E.g. Rubber ram strainer of 100 mesh allowing for an output of approximately 600 kg of commercial grade 60 durometer EPDM per hour.

- Precision The rubber ram can maintain a pressure of up to 20 MPa when utilizing standard equipment, and up to 40 MPa when used with high pressure equipment. It is suitable for processing EPDM, NBR, FKM and other types of rubber, with a maximum filtration level of 300 meshes, and up to 500 meshes for silica gel. The ram is preferred to the screw machine due to its increased filtration accuracy.

- Stability The ram extruder produce less heat, which makes it more stable than screw extruder. Additionally, sulfur can be added to prevent rubber scorching, thus improving filtration.

- Convenience The barrel is conveniently designed to be disassembled and removed, making it easy to clean and replace the raw material. There are no inaccessible areas, which allows for thorough cleaning.

- Safety Reliable systems and interlock devices can help prevent work-related injuries.

- Automation Processes regulated by PLC and touch screen controls, as well as a database for storing process parameters. This makes it easy to utilize and requires minimal user-training.

Details

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos