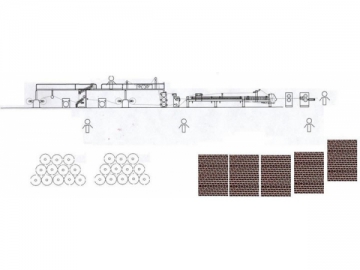

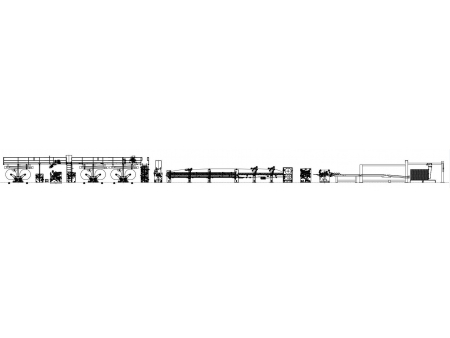

7 Ply Corrugated Cardboard Production Line

S-1500H Oil Pressure Roll Stand

The RS-1500H oil pressure roll stand is dedicatedly designed to hold up the corrugated medium roll and fasten it in the air, for the purpose of offering corrugated medium continuously.

Features

1. The hydraulic roll stand can support 2 paper rolls at the same time, thus achieving non-stop paper change.

2. The machine is fully controlled by hydraulic pressure from 6 hydrocylinders. For example, such movements as arms' going up and down, tightening and opening as well as moving left and right is controlled by hydraulic pressure.

3. The arms are constructed from cast iron and features curve structure, thus embodying great fastness and stability.

4. It is provided with oil pressure system.

5. Excellent tension control is realized by multipoint pneumatic brake which comes with great performance and fast heat dissipation as well as air pressure valve, pressure regulating valve and pressure gage.

6. Internal mount paper roll clamp is typically designed. This top design can not damage the corrugated medium and put it into complete use.

Specifications

Maximum paper width: 1800mm

Maximum ID of corrugated medium roll: Ø1500mm

Minimum ID of corrugated medium roll: Ø350mm

Hydraulic Paper Roll Carrier

The paper roll carrier is controlled by hydraulic pressure carrying the corrugated medium roll to the roll stand, thus reducing labor intensity. In addition, quick paper changing can be achieved.

Features

1. The paper roll carrier is provided with a sliding plate traveling on two sliding rails with its four wheels.

2. Moving forward and back is controlled by electric oil pressure, thus ensuring easy operation and quite low failure rate.

Multilayer Pre-heater for Liner and Corrugated Paper (Automatic Rotating)

This pre-heater is used for heating liner paper and corrugated paper and then drying them so as to control temperature and humidity.

Specifications

1. Maximum paper width: 1800mm

2. Diameter of pre-heater roll: Ø1000mm

3. The preheat roll features butterfly end socket structure and is provided with flexible siphon that ensures more thorough water draining.

4. Steam pressure: 1.2-1.4mpa

5. Guider roller: Ø110mm×2. One is fixed and another is movable. They are all made from steel.

6. Preheating range adjustment is controlled electrically.

7. It is driven by a 1/2HP motor, a turbine reducer and a group of swing arms (gear drive).

8. European brand electrical appliances such as ABB, Schneider, etc.

9. The gear motor used for adjusting wrap angle is made in China.

10. Rotary gear motor is Taiwan brand.

Cartridge Single Facer

Features

1. The flute type of the main corrugating roll is optional (flute type of tungsten carbide coated corrugating roll is specified by customers).

2. Special design of the corrugating roll under pressure roll lowers center of gravity of the machine, consequently reducing vibration.

3. The single facer features inner vacuum suction structure that can produce flatter paperboard.

4. Adhesive mechanism is driven separately and the whole part can move, thereby convenient for cleaning and maintenance.

5. Steam inlet and outlet employ quick connectors.

6. Corrugating roll, pressure roll, adhesive mechanism, fastening part, etc. are controlled by air pressure.

Specifications

1. Maximum machine speed: 250m/min

2. Working speed: 22-220m/min

3. Paper width: 2500mm

4. Diameter of upper corrugating roll: ¢408mm

Diameter of lower corrugating roll: ¢325mm

Material: chrome-molybdenum alloy steel

5. Diameter of pressure roll: ¢450mm

6. Diameter of glue roll: ¢310mm

7. Diameter of doctor roll: ¢190mm

8. Diameter of pre-heat roll: ¢500mm

9. Main motor power:45kw

10. Drive motor of gluing machine: 5kw(MITSUBISHI servo motor)

11. Glue amount control motor: 2×200w

12. Electrical equipment: ABB, Schneider, etc.

Overhead Bridge Conveyor

The overhead bridge conveyor is mainly used to deliver single face corrugated paper by belt to quadruple pre-heater.

Structure

1. The frame is constructed from structural steel.

2. Two sets of bridge are separately mounted above each single facer and above corrugated medium preheat roll.

3. On the bridge, a belt conveyor is set. Its speed is synchronous with single facer speed. It is driven by 3 motors.

4. The overhead bridge is provided with 2 rows of handrails and 3 groups of stairs. The walkway is paved by 150mm rectangular tubes and 1000mm steel gratings.

Specifications

Maximum paper width: 2500mm

Traction motor: 3×5kw

Electrical equipment: ABB, Schneider, etc.

Electric motor: TECO, CPG, etc.

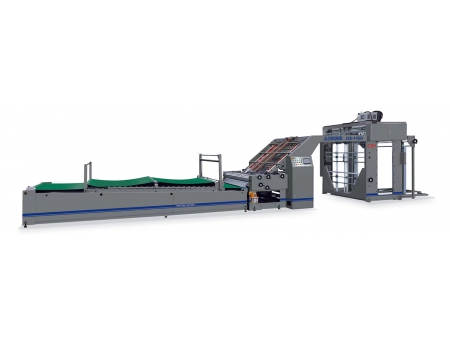

Double Gluing Machine

The double gluing machine is mainly used in triple wall corrugated cardboard production line for applying glues on the flute tips of the single face corrugated cardboard.

Specifications

1. Maximum paper width: 2500mm

2. Maximum production speed: 250m/min

3. Glue roll: φ318×3; it is made of steel and comes with cylindrical grinding; the surface is coated with hard chrome and pressed with diamond patterns.

4. Rider roll: φ200×3; it is made of carbon steel; roll surface is ground and plated with hard chrome.

5. Guide roll: φ110×6; it is made of steel pipe with surface polished.

6. Pneumatic cylinder: 6 pneumatic cylinders used to control up and down movement of rider roll; electrical adjustment is used in interval time.

7. Synchronized setting up: The double gluing machine is provided with servo motor for controlling running speed so as to be synchronized with double facer.

8. Glue thickness can be automatically adjusted by PLC according to speed.

9. Electric glue separating function.

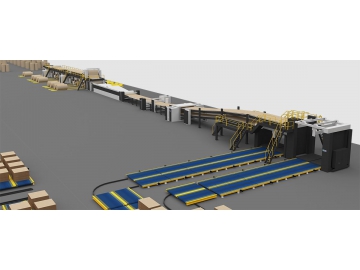

Hot Plate and Cooler

The hot plate is used to heat the glued paper and the cooler cools it and form cardboard.

Hot Plate Specifications

1. Steel hot plate: 20×150mm×600mm×2660mm

2. The welded hot plates are free from internal stress.

3. 12 groups of press plates fixed on the hanger plates at two sides are used to press paperboard on the hot plates.

4. A pneumatic system is offered to control the press plates.

5. The conveyor will automatically rise when power's off and can be put down manually when power's on.

6. Upper conveyor is provided with a tension controller and position correcting device.

7. A group of left and right adjusting units are equipped to adjust the conveyor.

8. Steam pipes

1) inlet pipe: φ 4 inch seamless steel pipe

2) outlet pipe: φ 3 inch seamless steel pipe

Cooler

Features

1. Upper cooler comes with pressing plate structure while the lower cooler pallet structure

2. A set of tension controller and position correcting device is provided for lower conveyor.

Specifications

Maximum paper width: 2500mm

Maximum machine speed: 250m/min

Drive Part

The drive part, linking up the drying part and cooling part, is mainly used to offer power to them.

Structure

1. The drive part consists of a main frame that is constructed from steel plate and structural steel as well as two rubber coated rolls and a guide roll.

2. Independent oil immersion type gearbox

3. 2 DC motors with total power of 112kw are the main drive motor.

Specifications

Maximum paper width: 2500mm

Maximum machine speed: 250m/min

Main Accessories

Electrical equipment: European brands such as ABB, Schneider, etc.

HTDX2500 Slitter Scorer

Technical Parameters

| Paper width | 2500mm |

| Number | 7 slitter knifes and 12 scorer heads |

| Min. slitting width | 180mm |

| Min. scoring width | 75mm |

| Positioning accuracy | 1mm |

| Adjustment range | ±70mm |

| Set up time | 8-15 sec, 10-18 sec, 10-20 sec |

Mechanical Properties

| OD of knife | Φ200-240mm |

| Slitting method | Independent slitting |

| Bottom slitter knife roll | Replacing knife holder |

| Upper scorer head | OD Φ180mm |

| Lower scorer head | OD Φ180mm |

| Scoring method | Overall scoring |

| Paperboard traction method | Traction by upper scorer head |

| Scoring line type | explosion-proof line, flat line |

| Smooth method | Φ100mm smooth roll |

| Line type change | Pneumatic method |

| Scoring depth adjustment | 0-16mm |

| Scoring depth display | Digital display |

| Scoring depth independent adjustment | ±1mm |

Computer Control System

Features

1. The computer control system can be operated through a human-computer interface.

2. It has super large capacity for storing orders.

3. Order input, revision and cancel can all be done in the system.

4. Slitter knife re-sharpening can be control by computer. Re-sharpening length and time for any one knife can be set alone.

5. Deviation of slitting and scoring can be corrected by computer.

6. Working performance of each system can be adjusted through computer.

7. It comes with an excellent fault diagnosis system. Remote diagnosis can be done by special fault code.

Configuration List

| No. | Equipment Name | Brand |

| 1 | AC servo motor | Japan Mitsubishi |

| 2 | PLC | Japan Mitsubishi |

| 3 | Frequency converter | Korean LG |

| 4 | Low-voltage apparatus | Korean LG |

| 5 | Ball screw | Taiwan PMI |

| 6 | Linear guideway | Taiwan AMT |

| 7 | Magnetic valve | Korean YSC |

| 8 | Button, switch | Korean KACON |

| 9 | Air pipe, connector | Korean SANG-A |

Note: customer provides 6-8kgf/cm2 clean compressed air (air separate air pump produces is recommended)

HTHX2500 Cutter Off

Technical Parameters

Maximum board width: 2500mm

Production speed: 220m/min

Range of cutting length: more than 800mm

Cut precision at constant speed: 1mm

Cut precision at special speed: 3mm

Features

1. Knife roll: rotary type

2. Main motor: AC servo motor (German BAUMLLER brand)

3. Driving method: frequency drive

4. Infeed section: drawer type movement convenient for adjusting knife; double sun wheel combined for dragging paperboard

5. Outfeed section: double sun wheel combined for delivering paperboard

6. Cutting way: cutting with fixed length

7. Time of cutting length change: instant

8. Lubricating section: forced lubrication by high pressure oil pump

9. Mode of operation: manual paper sheet feeding; Automatic feeding can be achieved under combination of customers

10. Maintaining method: inching, electric, rotating

11. Production support system: standby external data manual input device (control and display)

12. The cutter off comes with a efficient computer control system which has the same functions with that of slitter scorer

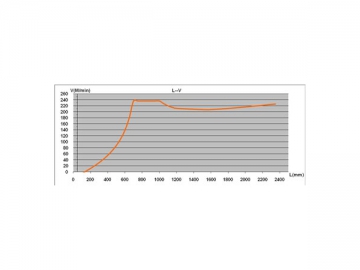

Cutting Movement Curve

V-Maximum production speed

L-Paperboard length

Configuration List

| No. | Equipment Name | Brand |

| 1 | AC servo motor | German BAUMLLER |

| 2 | AC servo driver | German BAUMLLER |

| 3 | Encoder | German SICK |

| 4 | Bearing | Japan NSK |

| 5 | Frequency converter | Korean LG |

| 6 | Low-voltage apparatus | Korean LG |

Main Technical Parameters of 7 Ply Corrugated Cardboard Production Line

| Mechanical Speed | 80-250m/min |

| Economic Speed | 110-180-200m/min |

| Working Width | 1600-2500mm |

| Dimensions | About 120m×9m×5.2m |

| Corrugated Types | BBE (Or depending on customer's demand) |

| Power Supply | 380V 50Hz (three-phase four-wire system, total power is about 650kw. |

| Paper Delivery Direction | Whether it is toward left or right depends on the actual situation of user's workshops |

| Steam Consumption | 5000kg/h |

Notes: The corrugated medium used for testing should comply with following requirements.

1. Grade: B or higher.

2. Water content: 11% ± 1%.

3. Surface paper: 120-200g/m2

4. Core paper: 90-125g/m2

5. Liner paper: 90-150g/m2

6. Corrugated paper: 90-125g/m2

Parts Provided by Customers

1. Main pipe of air compressor and main pipe of glue

2. Power supply, wire and wire pipe

3. Water, water pipe and bucket

4. Foundation of water, electricity and steam supply

5. Raw paper for test run, corn starch, industrial caustic soda, borax, etc.

6. Engine oil, lubricating oil, hydraulic oil and lubricating grease

7. A 6t steam boiler (steam pressure is 1.6mpa)

Quotation of 7 Ply Corrugated Cardboard Production Line

| No. | Equipment | Quantity | Remarks |

| 1 | Heavy duty no-shaft roll stand | 7 | Fully hydraulic drive, internal paper roll clamp, hydraulic system, multipoint brake, stroker |

| 2 | Hydraulic paper roll carrier | 14 | Containing paper roll carrier and rail |

| 3 | Pre-heater (surface paper) | 3 | ¢1000, electric rotating, wrap angle adjusted electrically |

| 4 | Cassette singer facer | 3 | C, B, B types tungsten carbide corrugating roll (¢408), lower corrugating roll (¢325), pressure roll (¢325); Glue amount can be automatically adjusted by PLC according to velocity ( E type spare roll is available) |

| Spare corrugating roll | 1 | Surface is coated with tungsten carbide; One electric cart for changing roll can be enjoyed. | |

| 5 | Pre-heater (core paper) | 3 | ¢1000; electric rotating; the wrap angle can be adjusted electrically |

| 6 | Overhead bridge | 1 | 3 sets of paperboard collecting devices |

| 7 | Quadruple pre-heater | 1 | ¢1000, electric rotating, wrap angle adjusted electrically |

| 8 | Secondary gluing machine | 1 | Japan famous brand main shaft; automatic glue amount adjustment; electric doctor roll, color touch screen, servo drive |

| 9 | Drying and forming system | 1 | 600mm×20 heat plates with surfaces ground and polished; the heat plates and cooler features pressing plate structure, PLC control and fully sealed appearance. |

| 10 | Drive | 1 | Independent reducer, 2 DC motor, imported rubber coating |

| 11 | Velocity measurement platform | 1 | Detecting and tracking the travel speed of corrugated cardboard |

| 12 | Stacker | 1 | Automatic stacker system with two layers, automatic chain type cart and six terminals. |

| 13 | Electrical apparatus control system | 1 | Famous brand electrical apparatus including electric motor, reducer, touch screen, glue machine and PLC are utilized. |

| 14 | Steam system | 1 | Taiwan brand steam trap; automatic temperature control; temperature display; pipes should be provided by customers. |

| 15 | Slitter scorer | 2 | Seven knifes and twelve lines; exhaust opening is included. |

| 16 | Roll stand | 1 | |

| 17 | Cut-off knife (single edge) | 2 | Servo motor and driver |

| 18 | Air systems | 1 | Rotary screw air compressor is needed (customer choose and buy) |

| 19 | Automatic glue making machine | 1 | Customer choose and buy |

| 20 | Exhaust system | 1 | Fan is included; customers prepare pipes |

| 21 | Automatic splicer | 7 | Customer choose and buy |

| 22 | PMS | 1 | Customer choose and buy |

| 23 | Digital display | 1 | Customer choose and buy |

| 24 | Automatic overhead bridge error corrective device | 1 | Customer choose and buy |

| Price: 9.04 million CNY (15-24 items that worth 3.95 million CNY are not included ) | Total price: 12.99 million CNY | ||