Side Bolt

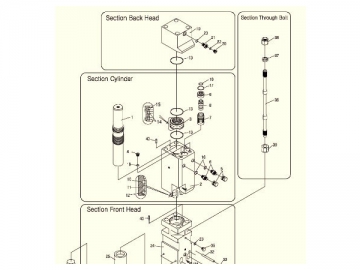

A hydraulic breaker usually comes with a bracket, which facilitates the installation of the breaker onto an excavator, loader, road roller or other construction machinery. The breaker is attached to the bracket by means of side bolts.

Selecting a quality side bolt for hydraulic breakercan be a touch decision to make as you have to contend many variables such as price and quality. One thing we can help with is to choose the nearest eligible alloy steel supplier who is generally 10km to 30km from us. Getting a nearby supplier saves raw material transportation cost so that customers can reap more cost savings.

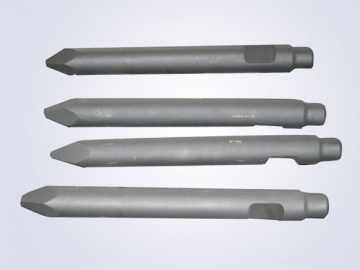

High quality alloy steel, together with state of the art manufacturing technologies, is what sets us apart from other side bolt manufacturers. Special heat treatment gives the bolt extra mechanical strength and makes sure every bolt is rugged, reliable and built to last.

We have over a decade of experience in the manufacture of construction machinery parts. We invest in human resources by hiring experienced engineers, technicians and craftsmen. We also invest in advanced manufacturing equipment which takes care of each step of production. After rough machining, the workpiece is heat treated to increase its hardness, ductility, and rupture resistance. After that, threads are rolled on the steel round bar. The threaded bar then receives a coating of white oil to protect against rust. Bolt washers and nuts are threaded onto the alloy steel side bolt before it is properly packaged for delivery.

For over a decade, many well-known hydraulic breaker manufacturers and agents who represent construction project contractors have turned to us for their excavator hydraulic hammer parts solutions. Our hydraulic breaker attachments are widely found on various construction sites.

At CHIXIN, we strive to hold the line on quality while still giving ground on price. We stock a wide range of parts for various makes and models of your hydraulic breakers. For any breaker-related questions, please feel free to contact us.

Alloy Steel

Chemical Components

C: 0.38~0.45%

Si: 0.17~0.37%

Mn: 0.50~0.80%

S: residual content≤0.035%

P: residual content≤0.035%

Cr: 0.90~1.20%

Ni: residual content≤0.030%

Cu: residual content≤0.030%

Mo: 0.15~0.25%

42CrMo

Permissible stress: 186~310/MPa

Yield strength: 930σs/MPa

42CrMo has high mechanical strength, hardenability, and ductility. It does deform much throughout quenching. When subjected to high temperatures, 42CrMo shows high creep strength and durability. The material is often selected to make more rugged side bolt.

Mechanical Strength

Tensile strengthσb (MPa):≥1080(110)

Yield strength σs (MPa):≥930(95)

Percentage elongation δ5 (%):≥12

Reduction of area ψ (%):≥45

Impact energy Akv (J):≥63

Impact toughnessαkv (J/cm2):≥78(8)

Hardness:≤217HB

Prototype sample size:25mm