Variable Frequency Drive

The variable frequency drive, also known as micro drive or AC drive, is a type of adjustable-speed drives used in electro-mechanical drive systems. The variable frequency drive is widely applicable to various manufacturing fields, providing strong support for application of new technologies and industry innovations.

- Especially designed for the photovoltaic market to achieve economic efficiency and eco-friendliness, the VEICHI-SI10 series solar pumping inverter is a great solution for PV pumping systems. It needs no battery modules and allows for water pumping and storage without electric power supply.

- The vector control frequency inverter supports high torque control even under low speed conditions. It ensures highly sophisticated motor control, by offering high speed precision, quick torque response, and wide speed range.

- The variable speed drive is able to effectively suppress the noise of motor and reduce the disturbance to peripheral equipment. It is available with input phase loss and output phase loss protections to protect the air compressor motor.

- This variable frequency drive is a selection of vector control frequency inverter newly designed for the purpose of permanent magnet synchronous motor speed control in air compressor industry. It is an efficient motor control solution for variable speed air compressors.

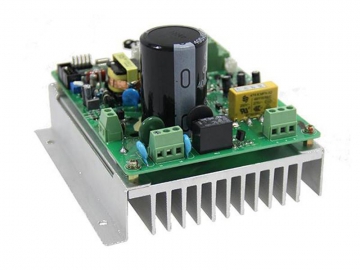

- The variable speed drive is integrated with the braking unit, brake power supply, and kinds of logical control unit. LED status indicators and clear printing marks are available to indicate various input and output limits, emergency stop signal, etc.

- We mainly supply three different types of variable frequency drives to assist in tower crane control. The AC80T-B variable speed drive is especially designed to control the luffing mechanism of tower cranes. Based on advanced current vector control technology, it supports large torque output under low motor speed conditions.

- The AC60E mini general purpose frequency inverter is our independently developed electrical equipment. As a new generation of high-performance V/F control drive, it is featured to have modular design, small size, small temperature rise, low noise, and reliable performance.

- The general purpose/fan and pump frequency inverter adopts the industry-leading V/F control, which resembles the vector control. It is a reliable, feature-rich inverter drive.

Industry-leading V/F control-the performance resembles that of a vector control frequency inverter.

Based on the AC60 series, we modified the structural design and created this AC60G engineering frequency inverter.

A powerful master-slave control is an advantage of this industrial automation device. The power synchronization and speed synchronization required by the rigid and flexible connection between master and slave machines are both realized, thus enabling uniform load distribution and multi-motor drive.

This motor controller is a dual-mode machine, supporting V/F control and open-loop vector control.

The AC70 sensorless vector control frequency inverter has beautiful appearance and stable quality. This motor controller is a dual-mode machine, supporting V/F control and open-loop vector control.

By the use of advanced motor model algorithm, the open-loop torque control can be achieved by closed-loop algorithm.

The AC80B high performance vector control frequency inverter has highly accurate speed and torque control, so it can perfectly meet the specific requirements of different industries. Three control modes are available: V/F control, PG vector control, and vector control without PG.

The world most advanced open-loop tension control technology is used by this variable speed inverter.

Rooted in China's tension control industry, the frequency inverter takes advantages of the local strength in the improvement of reliability, stability and ease of commissioning. So the drive excels its competitors in the tension control applications.

- The medium voltage variable frequency drive is the fruit of a secondary development and design based on sophisticated AC60/AC80 platform. The medium voltage inverter is prominent with high performance and high reliability.Using sophisticated AC60/AC80 platform for secondary development.

- Advanced current vector control technology is used by the AC80 machine tool frequency inverter, which is prominent with high speed precision and reliability. The inverter drive has great low frequency torque, as well as a zero servo function which means that this motor controller has a certain (adjustable) output torque at 0Hz running.

- Under the closed-loop control mode, the drive can complete a zero-servo function-180% of rated torque output at 0Hz. The steady-state accuracy is up to 0.02%, and the dynamic response time is less than 10ms.

The high-quality devices, advanced processing technology, and the conformal coating ensure reliable quality.

- By the use of advanced speed control technology, the AC80S construction hoist frequency inverter facilitates the technological innovation of the hoist electric drive system. The drive unit and brake unit are integrated, so there is no need for external brake unit. The dedicated logic control brake function improves the safety and reliability the hoist.

- There is great enough starting torque and the output torque can reach 180% of the rated one at low speed. It meets the requirements for big loading capacity of the ball mill, ensuring that the motor runs stably in variable frequency state.

- Excellent in anti-dust, waterproof, anti-grease and anti-corrosion properties, the AC60 sealed frequency inverter has the advantage of protection in IP64 grade. The enclosed frequency inverter is widely used in printing and dyeing, textile, cement, coal, ceramics industries and other harsh industrial conditions with heavy dust, moisture and high temperature.

- The AC61 injection molding machine frequency inverter is made with our technology in the field of motor drive. It is a dedicated model for injection molding machine. The superior quality, performance and energy conservation are perfectly blended. This variable frequency drive is applicable to all kinds of dosing pump injection molding machine.

- With superior quality and performance, the AC62 wire drawing machine frequency inverter provides an effective energy conservation solution for drawing machines. The tension control inverter is a new type of inverter drive for winding industry, metal wire drawing industry, and wire and cable industry.

- The AC65 cut-to-length machine frequency inverter is a professional electrical control solution for cut-to-length machines. The inverter drive achieves fully automatic control without PLC and high cutting precision, ensuring that the edges of products are cut neatly.

- The BU20 braking unit for VFD is mainly used in occasions where the mechanical load is relatively heavy and requires a very fast speed braking. The renewable energy generated by the motor is consumed by the braking resistor, or the regenerative current is reclaimed by the circuit.

- The RS485 communication module is dedicated for the communication expansion of AC60 series frequency inverter. Only with this communication module, the AC60 series (excluding AC60B) can be capable of Modbus communication.

- When an AC60/AC80/AC90 series frequency inverter is inserted with this Profibus-DP card, it will have access to any Profibus-DP network. The Profibus DP is much preferred with its high speed and low cost advantages.

The Profibus-DP card is widely used in manufacturing automation, industrial process automation and building automation.

- In operation and shutdown states, the LCD digital operator can display parameters of two monitored items simultaneously.

Run, stop, and fault states are indicated by vivid icons, allowing users to quickly understand and remember the state of the frequency inverter.

- The AC80PG card for VFD is mainly used on the vector control inverter (AC80B series). The function of inverter PG card is to send feedbacks about the motor speed and direction, to achieve more precise control of the motor speed and direction.

- The signal converter is dedicated for VFD of injection molding machine to achieve energy conservation. The function of it is to acquire and process the signal of pressure and flow rate.