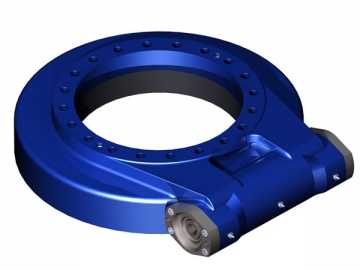

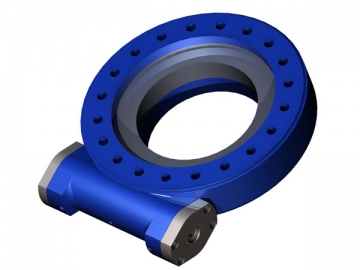

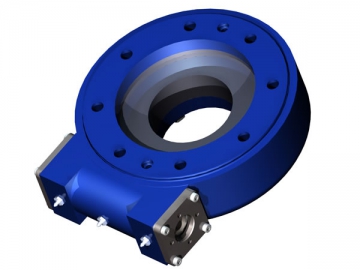

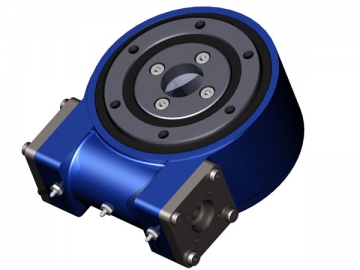

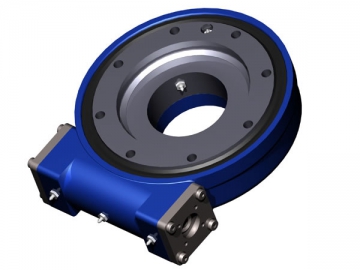

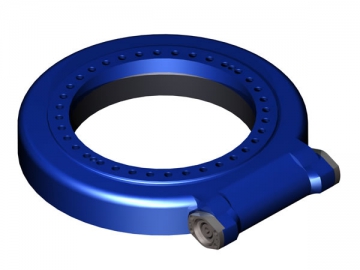

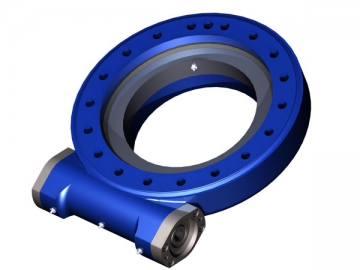

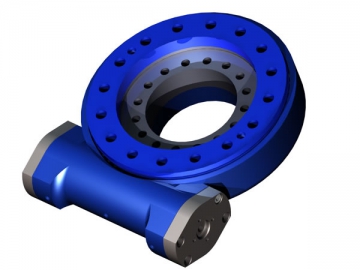

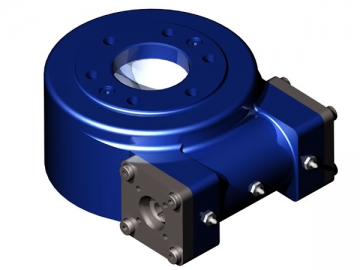

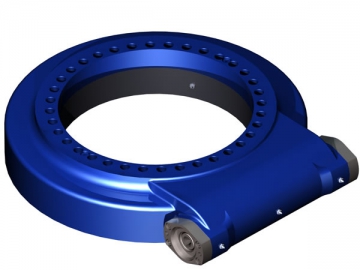

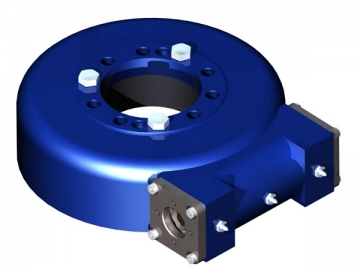

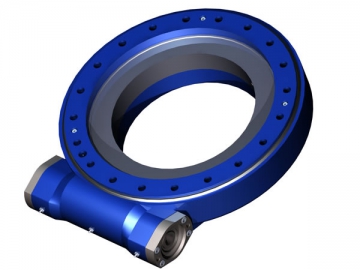

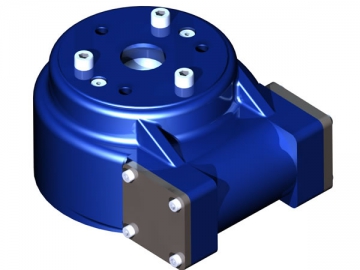

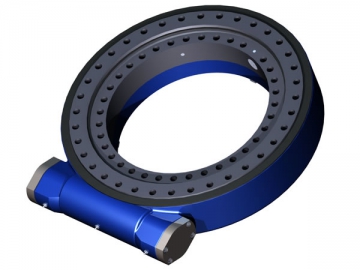

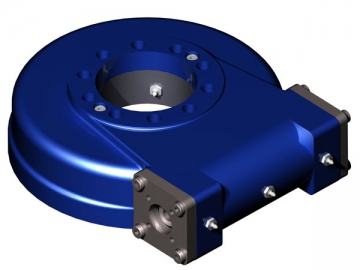

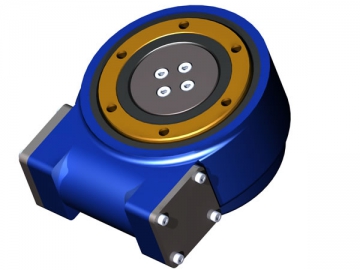

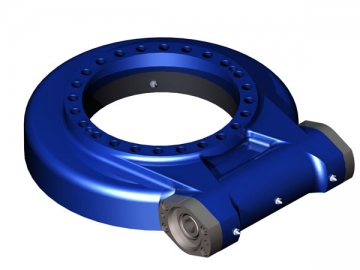

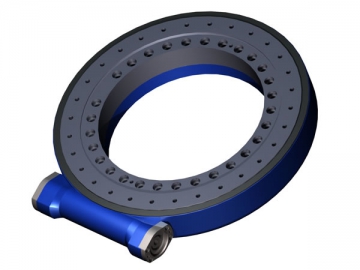

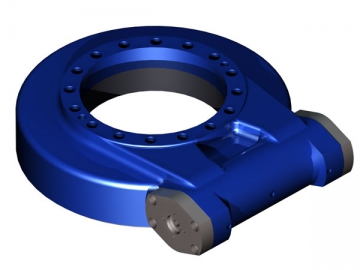

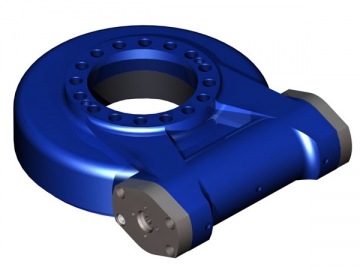

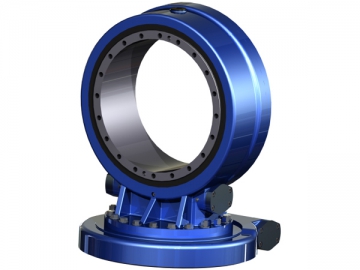

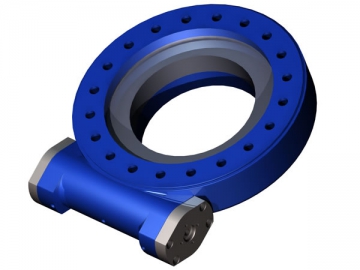

Description

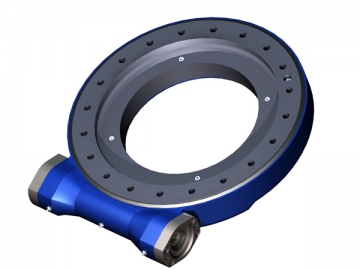

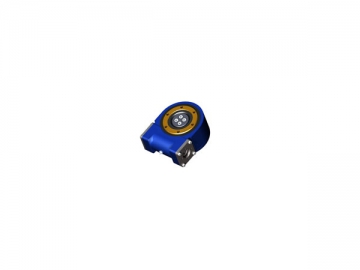

If you want to control the transmission accuracy within the range of 0.05 to 0.15 degrees, our PE series horizontally mounted slewing drive is absolutely the ideal choice. For concentrated solar power systems, the requirement on solar tracking precision is very high. If the chip fails to track the spot in real time, the power generation efficiency will be greatly reduced. Our high precision slewing drive can perfectly solve this problem.

Features

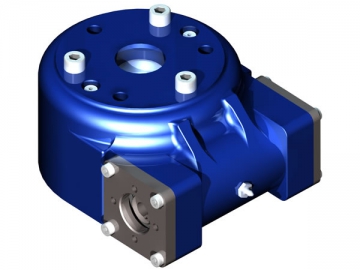

1. This industrial slewing drive is originally developed for precision tracking for the solar thermal power generation tracking system and photovoltaic power generation tracking system. Later, it is gradually applied in the field of precision transmission.

2. Due to the adoption of the latest technology, the tracking precision of our worm gearing reaches 0.05° or higher.

3. This series of slewing drive is designed with flexible input interface type, which facilitates the connection of various hydraulic motor and gear motor.

Supply Capacity

We are able to offer gear reducers in the shortest possible time. Custom made slew drives are also available.

Application

The horizontal precision slewing drive is widely applied in the solar power and machinery fields.

a. Drive the heliostat, trough solar thermal power generation system, dish solar thermal power system, and concentrating solar power system to rotate in the horizontal and pitch directions

b. Control the rotation of automated assembly line butt joints

c. Control the rotation of the welding positioner workbench

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| PE3C | 400 Nm | 1100 Nm | 2000 Nm | 30 kN | 16.6 kN | 9.6 kN | 8.4 kN | 62 : 1 | Ⅰ:≤ 0.08° | 12kg |

| 295 lbf•ft | 811 lbf•ft | 1475 lbf•ft | 6744 lbf | 3732 lbf | 2158 lbf | 1888 lbf | Ⅱ:≤ 0.12° |

| Ⅲ:≤ 0.15° |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| PE5A | 600 Nm | 3000 Nm | 5500 Nm | 45 kN | 22 kN | 14.4 kN | 11.1 kN | 62 : 1 | Ⅰ:≤ 0.05° | 20kg |

| 442.5 lbf•ft | 2212.5 lbf•ft | 4056.25 lbf•ft | 10116 lbf | 4945.6 lbf | 3237.1 lbf | 2495.3 lbf | Ⅱ:≤ 0.08° |

| Ⅲ:≤ 0.12° |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| PE5C | 600 Nm | 2800 Nm | 5500 Nm | 45 kN | 22 kN | 14.4 kN | 11.1 kN | 62 : 1 | Ⅰ:≤ 0.05° | 16kg |

| 442.5 lbf•ft | 2066.4 lbf•ft | 3690 lbf•ft | 10116 lbf | 4945.6 lbf | 3237.1 lbf | 2495.3 lbf | Ⅱ:≤ 0.08° |

| Ⅲ:≤ 0.12° |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| PE7 | 1500 Nm | 13500 Nm | 10400 Nm | 133 kN | 53 kN | 32 kN | 28 kN | 73 : 1 | Ⅰ:≤ 0.05° | 21kg |

| 1107 lbf•ft | 9957 lbf•ft | 7671 lbf•ft | 29900 lbf | 11915 lbf | 7194 lbf | 6295 lbf | Ⅱ:≤ 0.07° |

| Ⅲ:≤ 0.11° |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| PE7A | 1500 Nm | 13500 Nm | 10400 Nm | 133 kN | 53 kN | 32 kN | 28 kN | 73 : 1 | Ⅰ:≤ 0.05° | 25kg |

| 1107 lbf•ft | 9957 lbf•ft | 7671 lbf•ft | 29900 lbf | 11915 lbf | 7194 lbf | 6295 lbf | Ⅱ:≤ 0.07° |

| Ⅲ:≤ 0.11° |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| PE9A | 6.5 kN•m | 33.9 kN•m | 38.7 kN•m | 338 kN | 135 kN | 81 kN | 71 kN | 61 : 1 | Ⅰ:≤ 0.05° | 49kg |

| 4794 lbf•ft | 25×10^3 lbf•ft | 29×10^3 lbf•ft | 76×10^3 lbf | 30×10^3 lbf | 18×10^3 lbf | 16×10^3 lbf | Ⅱ:≤ 0.07° |

| Ⅲ:≤ 0.09° |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| PE12A | 7.5 kN•m | 54.3 kN•m | 43 kN•m | 475 kN | 190 kN | 114 kN | 100 kN | 78 : 1 | Ⅰ:≤ 0.03° | 61kg |

| 5532 lbf•ft | 40×10^3 lbf•ft | 32×10^3 lbf•ft | 107×10^3 lbf | 43×10^3 lbf | 26×10^3 lbf | 23×10^3 lbf | Ⅱ:≤ 0.05° |

| Ⅲ:≤ 0.07° |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| PE14A | 8 kN•m | 67.8 kN•m | 48 kN•m | 555 kN | 222 kN | 133 kN | 117 kN | 85 : 1 | Ⅰ:≤ 0.03° | 64kg |

| Ⅱ:≤ 0.05° |

| 5900 lbf•ft | 50×10^3 lbf•ft | 35×10^3 lbf•ft | 125×10^3 lbf | 50×10^3 lbf | 30×10^3 lbf | 26×10^3 lbf | Ⅲ:≤ 0.07° |

| Ⅳ:≤ 0.09° |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| PE17A | 10 kN•m | 135.6 kN•m | 72.3 kN•m | 970 kN | 390 kN | 235 kN | 205 kN | 102 : 1 | Ⅰ:≤ 0.03° | 105kg |

| Ⅱ:≤ 0.05° |

| 7400 lbf•ft | 100×10^3 lbf•ft | 53×10^3 lbf•ft | 218×10^3 lbf | 88×10^3 lbf | 53×10^3 lbf | 46×10^3 lbf | Ⅲ:≤ 0.07° |

| Ⅳ:≤ 0.09° |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| PE21 | 15 kN•m | 203 kN•m | 105.8 kN•m | 1598 kN | 640 kN | 385 kN | 335 kN | 125 : 1 | Ⅰ:≤ 0.03° | 149kg |

| Ⅱ:≤ 0.05° |

| 11000 lbf•ft | 150×10^3 lbf•ft | 78×10^3 lbf•ft | 359×10^3 lbf | 144×10^3 lbf | 87×10^3 lbf | 75×10^3 lbf | Ⅲ:≤ 0.07° |

| Ⅳ:≤ 0.09° |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| SE25 | 18 kN•m | 271 kN•m | 158.3 kN•m | 2360 kN | 945 kN | 590 kN | 470 kN | 150 : 1 | Ⅰ:≤ 0.03° | 204kg |

| Ⅱ:≤ 0.05° |

| 13300 lbf•ft | 200×10^3 lbf•ft | 117×10^3 lbf•ft | 531×10^3 lbf | 212×10^3 lbf | 133×10^3 lbf | 106×10^3 lbf | Ⅲ:≤ 0.07° |

| Ⅳ:≤ 0.09° |