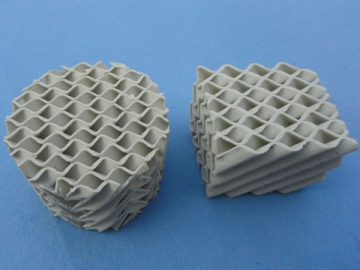

Anti-corrosion Packing

The anti-corrosion packing, also known as acid resistant brick, is a kind of corrosion-resistant material that is mainly fabricated from quartz, feldspar and clay through high temperature oxygenolysis, and it possesses many remarkable properties as illustrated below.

Feature

1. This packed tower internal has a low water absorption rate, and it is not likely to get oxidized at room temperature nor get contaminated by working media. Owing to its stable chemical property, our product is exceptionally resistant to chloride, hydrochloric acid, sulfuric acid, nitric acid and other acids (except hydrofluoric acid and hot phosphoric acid), as well as any alkalis with any concentration at room temperature (except concentrated alkaline solution).

2. Aside from its resistance to acid, alkali and other organic solvents, our anti-corrosion packing could also withstand sharp temperature variation during use.

3. There are some dovetail grooves on the back side of our corrosion resistant brick to realize firm connection with cement during installation, thereby avoiding the risk of peeling off.

Application

The anti-corrosion packing has found a wide range of applications in petrochemical, chemical, pharmaceutical, metallurgical, textile, fertilizer, pesticide, food processing, paper making, electric power and other industries, and it also fits for sewage treatment system, open ground and other workplaces. In addition, customized products are available if samples or relevant drawings are offered.

| Item | Unit | Data | Standard |

| Bulk density | g/cm2 | 2.31-2.4 | HG/T3210-2002 |

| Water absorption rate | % | >0.2 | GB8488-2008 |

| Acid resistance | % | 99.8 | GB8488-2008 |

| Bending strength | MPa | 42 | GB8488-2008 |

| Compressive strength | MPa | 120 | HG/T3210-2002 |

| Thermal stability | 130-20°C | 3 times without cracking | GB8488-2008 |

| SiO2 | Al2O3 | K2O | Na2O | CaO | MgO | Fe2O3 |

| 69.8% | 22.5% | 2.7% | 0.95% | 0.82% | 0.12% | 0.49% |

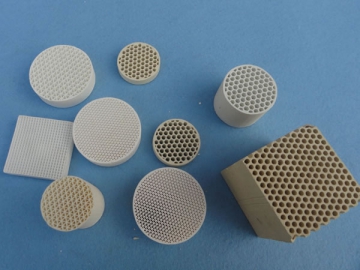

| Name | Size (mm) | Name | Size (mm) |

| Standard brick | 230×113×65 | Acid-proof ceramic brick | 100×110×15 |

| Rectangular brick | 230×65×65 | 150×150×15-30 | |

| Transverse wedge brick | 230×113×55/65 | 150×70×15-30 | |

| 230×113×25/65 | 100×100×10 | ||

| Endwise wedge brick | 230×113×55/65 | 80×80×10 | |

| 230×113×25/65 | 50×50×10 | ||

| Note: Other special-shaped bricks could be made-to-order according to drawings. | |||

Direction for Use

1. After corresponding tests are conducted to prove that liners are in accordance with relevant standards, please clean liners and keep them dry.

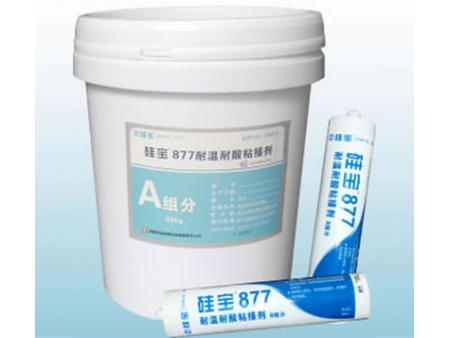

2. For smooth construction, the ambient temperature is recommended to be within 15-30°C, while the relative humidity shall not exceed 80%. On the other hand, the total amount of curing agent should be adjusted according to ambient temperature, and a dehumidifier should be used to regulate the temperature and humidity of installation site if the temperature is too low or the relative humidity is too high.

3. Please take measures to protect the construction project from water and sun exposure.

4. Plaster and sizing material must be prepared strictly following predetermined formulas, and they shall be used up within specified time period. In addition, it is forbidden to use plaster after initial set has been observed.

5. When laying our anti-corrosion packing, the entire brickwork should be tidy in both horizontal and vertical directions. The gap width is about 8-10mm, and the gap depth should be similar to the brick thickness. Please be noted that straight joint and bastard joint must be avoided, otherwise leakage may occur.

6. Use oxalic acid to wash the surface of concrete for the purpose of acid-base neutralization.

7. After construction job is finished, please use some oxalic acid to wash the surface of our anti-corrosion packing, and this is beneficial for solid connection.