Fried Instant Noodle Production Line

- Alkaline Water Weighing Tank

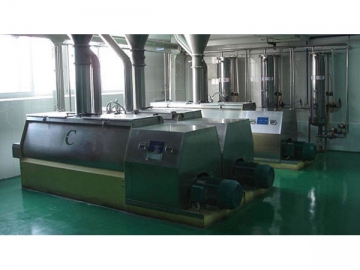

- Double Shaft Dough Mixer

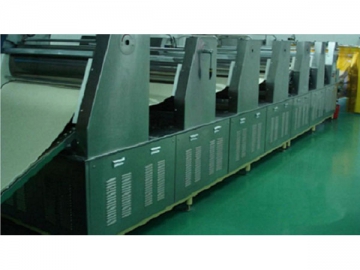

- Compound Rolling Machine

- Continuous Rolling Machine

- Multilayer Steamer

- Seasoning Machine

- Cutting, Folding & Dividing

Machine - Cutting & Distributing Machine

- Continuous Frying Machine

- Noodle Sheet Stacking Machine

- Cooling Machine

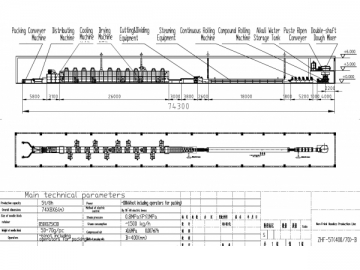

ZHY-(2-30)W-S Fried Instant Noodle Production Line Model

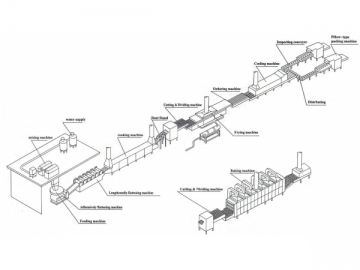

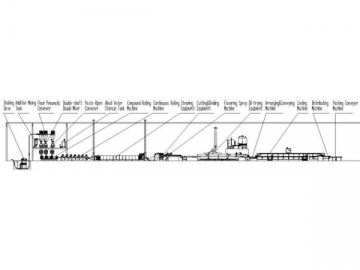

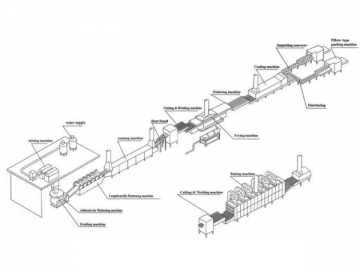

Axonometric Drawing

Our fried instant noodle production line consists of alkaline water mixer, weighing and spraying unit, double shaft dough mixer, compound rolling machine, continuous rolling machine, multi-layer steamer, seasoning machine, cutting & distributing machine, accumulating machine, continuous frying and dehydrating machine, noodle sheet stacking machine and air cooling machine. The actual configuration depends on the production needs of customers, namely, different combinations of machines are available.

Fried instant noodle is the precooked noodle fried in 145℃-160℃ oil, thus containing 18%-20% cooking oil. As a result, this instant snack is readily soaked in hot water and delivers enjoyable flavor. Therefore, most of instant noodles available on market are fried noodles. Generally, fried instant noodle comes in square or round shapes weighting 40-120g. Common package includes plastic bag, cup or bowl.

Advantage

1. Large Production Rate

Our fried instant noodle production line is able to produce 3,500 kg noodles per hour with minimized energy consumption.

2. High Automation

Variable frequency speed control, human-machine interface and PLC system are all available to ensure fast and easy control.

3. Optimal Structure

The entire food production system is presented in attractive layout. Enclosed cooling machine delivers impressive energy efficiency. Alloy iron rollers features excellent hardness and durability.

4. Standard Compliance

Our fried instant noodle machine stays remarkable tune in related hygiene requirements. Oil content is strictly controlled from 17% to 22%.

5. Retrofit Capability

In the interests of various customer needs, some parts of our fried instant noodle production line are allowed to be modified so that fitting specific food production requirements.

A. Rolling Machine

The rolling machine in this fried noodle sheet manufacture system can be driven by single or multiple electric motors. In the first model, only one electric motor drives all roller groups. Speed of each group is synchronously controlled when rolling machine is adjusting noodle sheet thickness. As for the second model, each roller group is fitted with exclusive motor. The rolling speed is PLC controlled with the aid of photoelectric switch installed in each group.

B. Steamer

Steamer in our fried instant noodle production line is variable in single layer and multiple layers. Normally, multi-layer model has 3 layers, thus using much less floor space comparing to single layer model.

Specification

| Model | Capacity (×10,000 pcs/8 hours) | Dimensions (m) | Power (kW) | Roller size (mm) | Staffing | Steam consumption (kg/h) |

| 2-3 | 48 × 6 × 6 | 36 | 210 | 4 | 800-1000 | |

| 4-5 | 56 × 6 × 6 | 48 | 320 | 4-5 | 1000-1200 | |

| 6-8 | 68 × 6 × 6 | 60 | 420 | 5 | 1200-1400 | |

| 9-12 | 74 × 6 × 6 | 78 | 520 | 5-6 | 1400-1600 | |

| 13-16 | 78 × 8 × 6 | 86 | 630 | 6 | 1600-1800 | |

| 17-20 | 82 × 8 × 6 | 92 | 735 | 7 | 1800-2000 | |

| 21-24 | 86 × 8 × 6 | 100 | 820 | 7-8 | 2000-2500 | |

| 25-30 | 95 × 8 × 6 | 112 | 1000 | 8 | 2500-3500 |

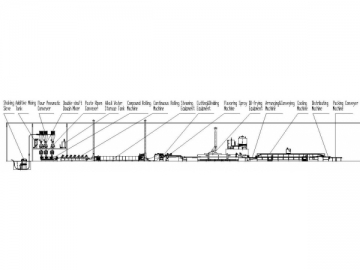

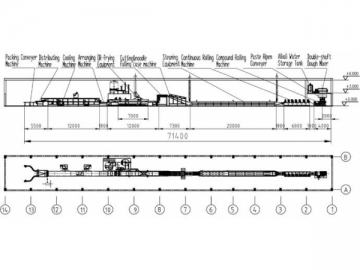

ZHY-10W(60080)-B2 1 Million Capacity Fried Instant Noodle Production Line 20130510-Model

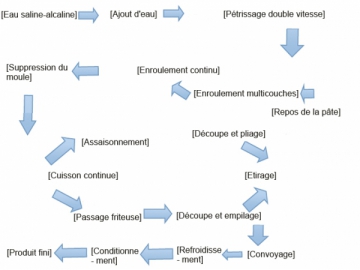

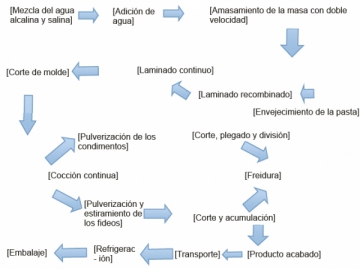

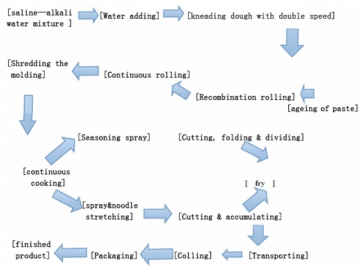

Production Process

Production Parameters

1. Water content in kneading dough: 28%-32%

2. Dough kneading time: 15-20 minutes

3. Steaming time: ≥120 seconds

4. Steaming temperature: 95℃-100℃

5. Noodle level: α:>90%

6. Frying temperature: 135℃-155℃

7. Frying time: 90s-110s

8. Air cooling time: 3-4 minutes