Rubber Belt Tumble Blast Machine

- Q32 Rubber Belt

Tumble Blast Machine - QR3210 Rubber Belt

Tumble Blast Machine - Q15GN Rubber Belt

Tumble Blast Machine

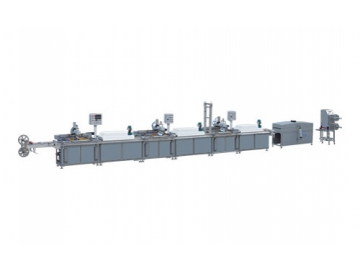

The rubber belt tumble blast machine is a tumblast machine available in three series which are Q32, Q15GN and Q28G. These products have different advantages in metal surface cleaning, and thus are suitable for different conditions.

Application

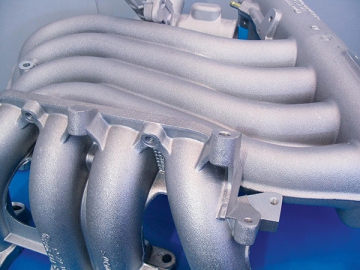

1. The Q32 rubber belt blaster could clean and strengthen surfaces of various kinds of small or medium sized castings, forgings and other metal parts. This abrasive blast equipment works as a stand-alone machine or in groups, and it can work together with belt conveyors to form a continuous metal cleaning line.

2. The Q15GN and Q28GN rubber belt blasters are used to remove oxidized layer and other contaminants from surfaces of castings, forgings and weldments, and they are also applicable for other metal parts, such as aluminum castings, nonferrous parts, hard-to-clean work pieces, easy-to-tumble work pieces, castings with small cavity depth, non-brittle metal components, etc.

System Configuration

Our rubber belt tumble blast machine is a complicated, high-tech product composed of the following parts.

Product Series 1: Q32 Rubber Belt Tumble Blast Machine

1. Shot Blast ChamberShot blasting chamber consists of chamber cover, disc plate, belt, and door. The chamber cover is made of steel plate and designed with beam structure. The belt is made of wear-resistant rubber and the disk plate is made of wear-resistant material.

2. Throwing Wheel AssemblyThe blast wheel assembly is primarily composed of blast wheel and turbine. In particular, our barrel blast machine is outfitted with QY360 blast wheel which is manufactured using Japanese technology, and it is cantilever driven by a 30kW turbine.

3. Bucket ElevatorThe bucket elevator is made up of cycloidal speed reducer, belt pulley (upper and lower), rubber belt, abrasive hopper, housing, tensioning device, and other parts.

4. Sand SeparatorOur sand separator uses air to remove sand, mill scale and broken shots from useable abrasives.

5. Dust Removal SystemDust removal system is used to remove the dust produced during shot blasting, preventing the pollution of the environment.

Product Series 2: Q15GN Rubber Belt Tumble Blast Machine

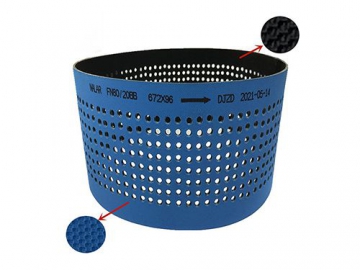

1. Shot Blast ChamberThe shot blast chamber is constructed by welding steel plate and profile steel, and it takes 12-mm-thick Mn13 wear resistant plates as its liners to protect the housing from shot impact. Inside the chamber, there is a throwing wheel (at the top), a rubber belt (with drive mechanism), a screw conveyor (at the bottom), a tight-sealed door (in the front) and lateral disks (at two sides).

In particular, inspection windows and access doors are designed at two sides and front low end of the shot blasting machine, so operators will find it extremely convenient to check the running condition of our rubber belt tumble blast machine before making adjustments. Moreover, a mesh screen is placed at the bottom of blast chamber, and it not only drains used shots, but also effectively prevents burrs and bulk materials from penetrating into the screw conveyor.

2. Perpetual CaterpillarThe perpetual caterpillar is formed by joining caterpillar plates that are produced by heat treated manganese steel. These plates have a T-shaped cross section to enhance rigidity, and their surfaces are not struck to achieve better flatness. In addition, these plates are connected to chain rings at two sides by bolts, and the chain rings are made from heat treated steel and are linked together by steel pins.

3. Throwing Wheel AssemblyFor our rubber belt tumble blast machine, its throwing wheel assembly is installed at the top of blast chamber, and it primarily consists of throwing wheel, turbine, belt pulley, V-belt and bed plate.

The applied Q180-4RK throwing wheel has a single runner head with several curved blades, and it is manufactured on the basis of PANGBORN technology, but we have made some improvement to provide eco-friendly, energy-saving and highly efficient performance.

As for the housing, it is welded by robot arms in one step, thus guaranteeing excellent dimensional and dynamic balance precision.

The impeller, control cage and blades are made from high chrome steel through investment casting for better wear resistance, thus significantly prolonging their life spans. For example, the impeller and control cage have a service life of over 1500 hours, thus there is no need to change them frequently. In this regard, our tumble blast machine has a short down time, and this is very helpful in cutting down production cost.

4. Bucket Elevator

The bucket elevator mainly comprises of cycloidal speed reducer, conveying rubber belt, belt pulley, HT150 hopper, housing and tensioning device. There is a pulse wheel on the lower shaft, and it is intended to monitor the working status of bucket elevator. If the elevator skids or fails to work, relevant signals will be sent to the PLC by this pulse wheel, so our rubber belt tumble blast machine is well protected.

The air wash separator takes advantage of an adjustable stream of air to separate fines and contaminants in abrasive mass which is spread like a waterfall. Accordingly, for abrasives that are going to be delivered into blast wheel, its impurity content is less than 1%, while in collected waste abrasives, there is less than 1% useable abrasives.

6. Screw Conveyor

For the screw conveyor, its screw blades are constructed from 16Mn steel to extend their expected life.

As indicated by its name, the abrasive silo is used to store abrasives, and it is placed underneath the air wash separator. On the other hand, the abrasive gate is at the end of abrasive delivery chute, and it is controlled by an air cylinder to offer reliable and stable performance.

8. Loading DeviceIt is used to transport work pieces into our machine.

9. Dust Removal SystemThe tumble blast machine makes use of a two stage dust removal system to collect more than 99% submicron-sized dust, and it is made up of dust collector, blower, settling box and pipelines.

10. Control System

This wheel blast cleaning equipment is controlled by a Siemens PLC controller either in automatic or manual mode (switchable), and its GGD electrical cabinet is IP54 rated.

Ordering Information

Our rubber belt tumble blast machine could be tailored according to customers’ needs, and customizable items include max. work piece size, number of throwing wheel, number of workstation, size of shot blast chamber, etc.

| Item | Unit | Data |

| Barrel size | mm | 1090×1245 |

| Lateral disk size | mm | Ф1092 |

| Charging volume | m³ | 0.43 |

| Max. single work piece weight | kg | 227 |

| Max. work piece size | mm | 1000 |

| Max. weight of load | kg/barrel | 800 |

| Abrasive consumption rate | kg/min | 480 |

| Power of throwing wheel | kW | 22 |

| Item | Unit | Data |

| Barrel size | mm | 1245×1778 |

| Lateral disk size | mm | Ф1250 |

| Charging volume | m3 | 0.79 |

| Max. single work piece weight | kg | 363 |

| Max. work piece size | mm | 1000 |

| Max. weight of load | kg/barrel | 3500 |

| Abrasive consumption rate | kg/min | 340×2 |

| Power of throwing wheel | kW | 30 |