Wire Mesh Belt Shot Blast Machine

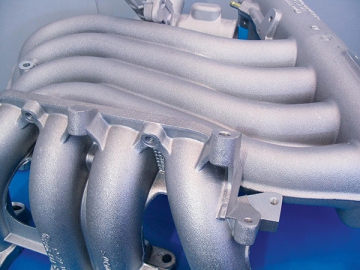

The wire mesh belt shot blast machine is commonly used in automobile, aerospace, railway and machine building industries for the purpose of shot blasting thin-walled iron castings or aluminum castings, and it is also capable of shot peening metal parts.

Working PrincipleOur wire mesh shot blast machine takes advantage of a wire mesh belt conveyor to transport work pieces into the fully enclosed blast chamber, and then the blast wheel assembly uses a high-speed rotating impeller to accelerate and spray abrasives onto the surface of work piece to realize thorough surface cleaning. In addition, this metal surface cleaning equipment is applicable for flat shaped castings, forgings and structural parts.

System ConfigurationThe wire mesh belt shot blast machine is mainly composed of the following parts.

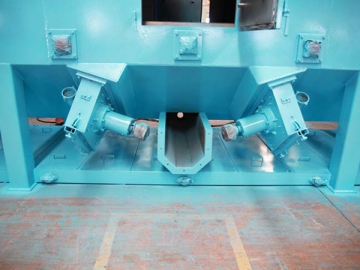

1. Blast ChamberConstructed by welding steel profiles and 16-mm-thick Q235 steel plates, the blast chamber boasts a robust structure, and it takes a layer of 16mm thick rolled Mn13 steel plates as its lining material to protect itself from shot impact. These protective plates, fixed by special nuts, are interchangeable, and their gaps are filled with 10mm thick rolled Mn13 steel.

On one side of the chamber, there is a safety door used to facilitate operators’ access, and it is equipped with a proximity switch to avoid misoperation and protect operators from injury.

2. Pre-Blastroom and Post-Blastroom

For our wire mesh belt shot blast machine, its pre-blastroom and post-blastroom are fabricated from steel profiles and 10mm steel plates via welding process, and they are lined with 6mm thick wear resistant rubber plates which are fixed by protective nuts to facilitate replacement.

On the other hand, these blastrooms are sealed by 8 layers of curtains to prevent splashing of abrasives, and highly wear resistant rubber plates are adopted to seal other positions.

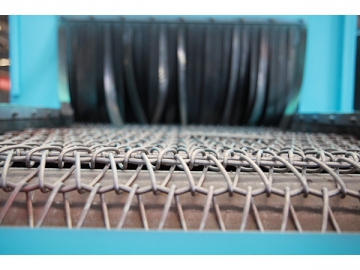

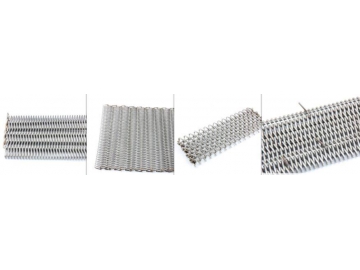

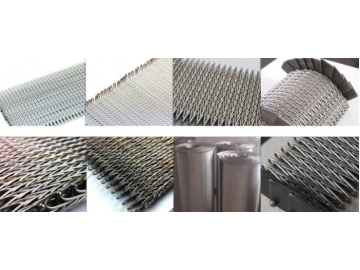

3. Work Piece Delivery SystemOur wire mesh belt shot blast machine’s delivery system is made up of wire mesh, drive roller, redirection roller, tensioning device and roller bed.

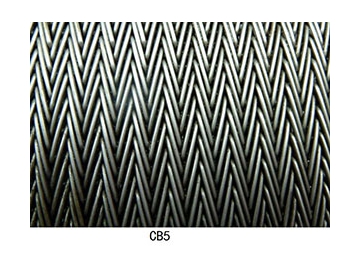

The horizontal wire mesh is manufactured from highly wear resistant manganese steel through special production process to extend its service life to as long as 3500-4000h, and it ensures that both upper and lower sides of metal parts are effectively cleaned in one step. In addition, the wire mesh belt conveyor is driven by a shaft-mounted speed reducer to realize stepless speed control, and a safety device is employed to make sure that workers won’t get in touch with moving mesh when this automatic shot blasting machine is still working.

The drive roller is made from large-diameter steel pipes, and its surface is coated with rubber to provide higher friction force between roller and wire mesh. For the roller bed, its shaft is fabricated by welding high-quality seamless carbon steel tube and tempered spindle noses.

4. Blast Wheel AssemblyOn the side walls of blast chamber, there are 8 blast wheel assemblies formed by blast wheel, turbine, bed plate and so on, and we use Q034 direct drive blast wheel that is manufactured according to Georg Fischer and DISA technologies to provide stable jets of abrasives. The location and angle of blast wheel assembly are determined by 3D dynamic simulation, so thorough surface cleaning result is delivered.

For safety considerations, this shot blast machine sets a proximity switch near the top cover of blast wheel assembly. So, operators won’t be injured even if misoperation is carried out.

5. Abrasive Reclamation SystemThe abrasive reclamation system includes screw conveyor, bucket elevator, sand separator, abrasive gate and other components.

6. Platform and Auxiliary FacilitiesRiffled steel plates and safety barriers are installed at the platform to protect operators from skidding, and there is a safety door at the junction of ladder and safety barrier. This door will be closed immediately when operators move on to the platform, so people won’t fall off the ladder.

7. Cleaning SystemThe wire mesh belt shot blast machine uses a high pressure blower and several blowpipes to blow away remaining abrasives and dust on the workpiece.

8. Dust Removal System

The dust removal system is constituted by dust collector, blower, settling box, cyclone dust extractor, pipelines and so on.

Our shot blast machine is controlled by a Siemens PLC controller, and its frequency converter is also supplied by Siemens while other electrical devices are either made by Siemens or Schneider. To achieve better control, a 7-inch Siemens touch screen is fitted.

There is a specialized switch to change working mode between manual and automatic, and inter-locking, self-locking and other safety functions guarantee safe running.

Ordering Information

Based on customers’ practical needs, we can design and manufacture tailored wire mesh belt shot blast machine by changing max. work piece size, number of blast wheel, number of work station, size of blast chamber and so on.

| Item | Data |

| Width of wire mesh belt | 1250mm |

| Max. load capacity | 1200kg |

| Max. work piece weight | 100kg |

| Max. work piece size (cross section) | 1000×500mm |

| Air requirement | 1500m3/h |

| Total power | 97.5kW |