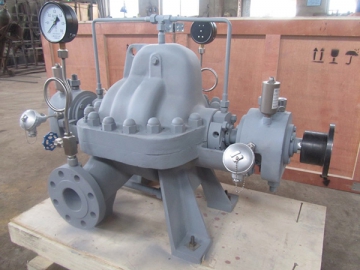

API610 OH1 Pump (Foot Mount Pump)

Properties

This API610 OH1 pump, designed based on the API610 pump, is a single-stage cantilever pump that is installed according to its center line.

Size : 1-16 inches

Flow rate: 0 -2600 m3 /h

Head : 0-240m

Temp. : -80-300 °C

Materials: Cast steel, 304 stainless steel, 316 stainless steel, 316 stainless steel alloy, stainless steel 316L, CD4MCu, titanium, titanium alloy and Hastelloy.

This API610 OH1 pump DAMEI provides to you is a reliable universal volute pump designed with a radial split structure. Now, 54 subtypes of this model available for customers, all of which adopt merely 8 models of bearing suspension units. To be more specifically, the bearing suspension unit always contains such four main components as the shaft, shaft seal, impeller and pump cover. It allows users to dismantle the pump without removing the imported flange and motor. Meanwhile, these volute pumps share the same hydraulic parts, bearings with the OH2 pumps, ensuring a minimum inventory of spare parts.

Structure of API OH1 Pump

1. Pump Body

The API610 OH1 pump of a caliber wider than that of the DN80 pump is designed with a double-volute casing. Its pump body is supported by foot and equipped with replaceable impeller rings which could be washed. The clearance between the pump body and the pump cover could be sealed by compressible flat metallic gasket

Flange

The suction flange of this API610 pump is mounted horizontally and the discharge flange vertically, both of which could satisfy the Guobiao standard, DIN standard or ANSI standard. Importantly, the two flanges could bear a large nozzle load and always enjoys the same pressure rating.

2. Water Balance and Axial Force Balance

Flange of a wider caliber could ensure a much lower flow rate of fluid. At the same time, both the impeller and pump body enjoys noise-reducing designs. The single suction radial-flow impeller of this OH1 pump is designed with a hermetically sealed passage. Moreover, we could provide pumps of this model equipped with inducers and open impellers according to your requirements.

The replaceable pump body and impeller rings of this could effectively protect the wearing parts. According to specific working conditions, the axial force could be balanced with the help of front impeller rings or the front and back impeller rings with balancing holes. And the residual axial force will be solved the thrust axis.

3. Bearings and Lubrication

The bearing suspension unit of this API610 pumping equipment enjoys an integrated structure. The bearings could be lubricated by oil bath. The constant level oiler could automatically adjust the oil level and the oil thrower could avoid local temperature rises caused by uneven lubrication of bearings. We could provide suspension units which could radiation rips, water cooling device or air cooling device(fan) according to specific working conditions where your pump is meant to operate.

4. Shaft Seal

The available shaft seal for this volute pump include the packing seal and mechanical seal. The maximum shaft run-out is 0.05 mm. As the pump cover is thermally insulated, every shaft seal could be filled with cooling liquid, flushing liquid and seal liquid. The standard pipeline could be designed according to the API Piping Plans.

5. Secondary Interface and Rotation Direction of API610 Pump

The secondary interface of this OH1 pump is applicable to the G-thread or the ZG thread (internal taper pipe thread). In most cases, we adopt the G thread in our products. The pump rotates in a clockwise way if you look at it from the drive section.

Advantages of API610 Pump

1. This API610 pump, manufactured with the standard processes, enjoys a scientific structure, easy to dismantle and maintain. Specifically, users could dismantle the pump without removing its pipes and motor.

2. 53 subtypes of this model are available for customers, all of which adopt only 8 models of bearings and could share the same hydraulic parts(impellers) and bearings with the OHI pumps -the light and medium duty pumps and the ZF and Zupumps-the heavy duty pumps.

3. This industrial pumping unit enjoys a much smaller radial force and deflection. Especially, the deflection of its bearing is smaller than 0.05mm. The flow rates at the inlet and outlet are quite low and the noise is lower compared with other pumps. Its impellers and pump body are thickened to increase their corrosion allowance.

4. Its shrouded impellers could operate smoothly and efficiently under any working conditions and enjoy lower cavitation erosion.

5. The open impeller is suitable to transport gas, liquid and solid-liquid media.

6. This pump enjoys extremely low cavitation erosion. Therefore, it requires devices of small cavitation erosion allowance.

7. The worn impeller rings and shaft sleeves could be replaced while the pump body, impellers and shaft remain to work well.

8. Its shaft and shaft bracket enjoy sound co-axial, high stability and strength and smaller deflection. The bearings don’t generate heat and need no cooling devices. Additionally, there is fewer Nk>N parts equipped in this pumping apparatus. Given this fact, users could spent less efforts in the inspection and maintenance of the bearings.

9. The packing seal and various mechanical seals, which are interchangeable with each other, are applicable to this pump.

Application of API610 Pump

This API pump is suitable to convey clean liquid, liquid contains with grains, low-temperature or high-temperature liquid, neutral or corrosive liquid. Therefore, it has been used in a wide range of areas such as the oil refinery, oil chemical, coal processing, chemical, paper and pulp making, sugar making and shipbuilding industries, water plants, desalinators, low-temperature projects, environment protection project and off sea projects and etc.