Electromagnetic Pure Iron

Soft magnetic material with purity greater than 99.5%

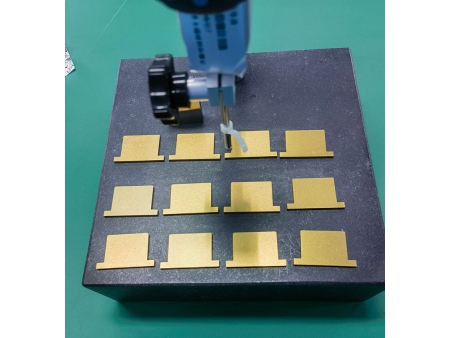

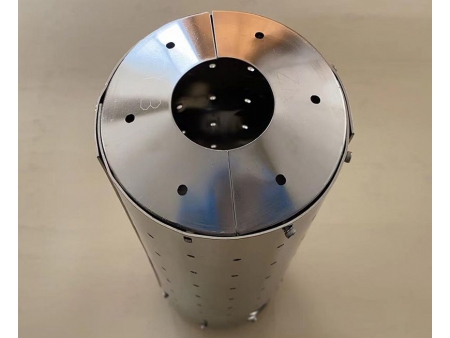

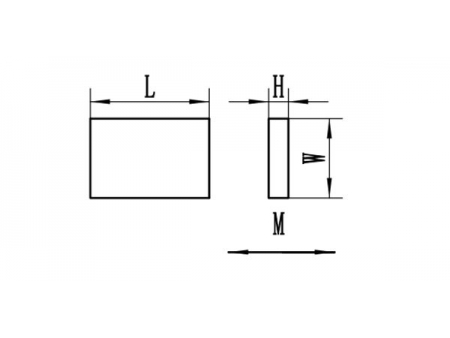

Unleash the Power of Purity: NGYC's Soft Magnetic IronSoft magnetic iron is a high-quality special magnetic steel with an iron content of over 99.5%. Its unique features include low coercive force (Hc), high permeability (μ), and high saturation flux density (Bs), making it ideal for applications that require high magnetic flux density under static low-field and low-frequency conditions. The material has high purity, a dense structure, and uniform organization, which makes it suitable for high-vacuum and magnetically stable applications. It can be easily processed using various mechanical methods, such as turning, punching, bending, and welding, and has excellent surface quality after processing. Our pure iron products are typically coated with a protective layer to prevent corrosion. Without this coating, pure iron may be susceptible to corrosion over time.

- Motor Equipment Industry: various iron cores, electromagnets, permanent motors, and DC motors

- Automotive Industry: automotive engines, and electronic components

- Medical Industry: medical imaging devices

- Telecommunication Industry: telecommunication devices, and accelerator

| Grade | Coercive Force Hc (Oe) | Max. Permeability μm | Magnetic Flux Density (Gs)* | |||

| B200 | B1000 | B5000 | B10000 | |||

DT4 | ≦1.2 | ≥6000 | ≥12000 | ≥15000 | ≥17000 | ≥18000 |

DT4A | ≦0.9 | ≥7000 | ||||

DT4E | ≦0.6 | ≥9000 | ||||

DT4C | ≦0.4 | ≥12000 | ||||

DT8 | ≦1.2 | ≥6000 | ≥12000 | ≥15000 | ≥17000 | ≥18000 |

DT8A | ≦0.9 | ≥7000 | ||||

DT8E | ≦0.6 | ≥9000 | ||||

DT8C | ≦0.4 | ≥12000 | ||||

DT9 | ≦0.8 | ≥14000 | B5 | B10 | B50 | B100 |

| ≥15000 | ≥15700 | ≥17000 | ≥18000 | |||

- 1: B5, B100, and B10000 represent the B values under conditions of H=200A/M, H=1000A/M, etc.

- 2: Pure iron DT8 has a vacuum leakage rate of ≦1X10-9Pa.m3/s.

- 3: The vacuum leakage rate of pure iron DT9 is better than that of pure iron DT8. Customers can conduct their own experiments to check.

- 4: The magnetic flux density values shown in the table represents the technical potential for each grade of pure iron and are for reference only. The actual value is closely related to other factors such as batch composition and heat treatment process.