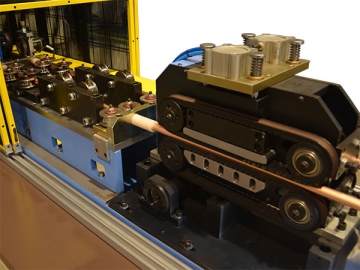

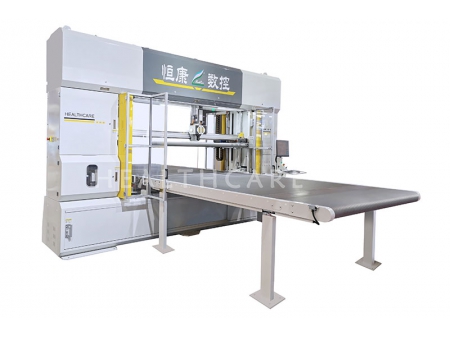

CNC Tube Processing Machine (Cutting / End Forming / Bending)

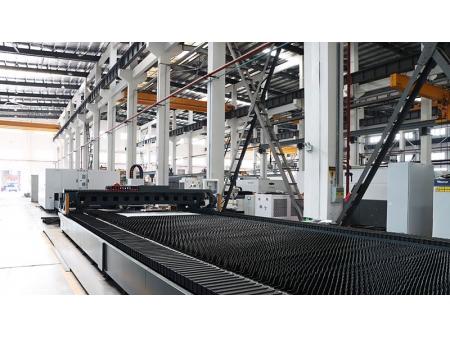

The integrated CNC tube processing machine (cutting/end forming/bending) is a 3D forming machine for air-conditioner pipes. It can straighten, size, cut, end form and 3D bend the coiled copper pipes, automatically.

It is mostly applied in tube forming for aeromotor, rocket motor, automobiles, household appliances, etc.

- Integrated CNC tube processing machine (cutting/end forming/bending)

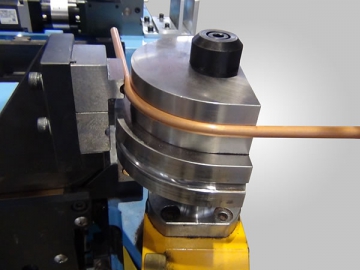

- Tube bending station

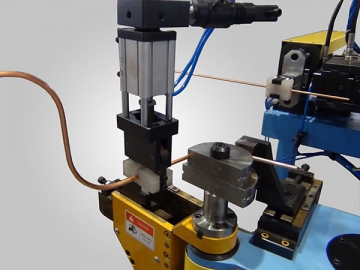

- Feeding by manipulator

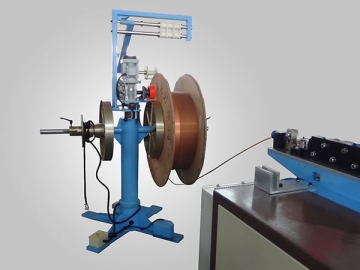

- Motorized decoiler

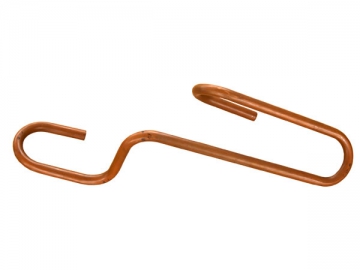

- Product

- Product

Features:

1. High degree of automation, can perform virtual processes

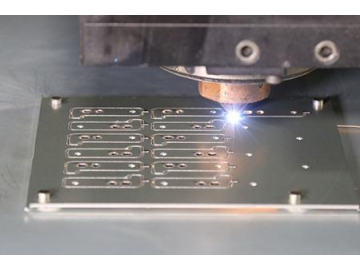

2. Chipless cut-off, CNC sizing, servomotor drive.

3. 3D CNC tube bending

4. CNC shift

5. Multi-station end forming

6. Stable working, low noise, high cutting accuracy.

7. Simple maintenance is, easy to operate.

8. Equipped with intermittent blade oil injection device that can prolong the life of blade.

9. Motorized decoiler.

10. Unloaded by pneumatic manipulator.

| Main technical parameters | ||||||||

| 1 | Bending part | Tube diameter×W. thickness | Ф15×1.6mm | 13 | Cutting part | One feeding journey | 700mm | |

| 2 | Bending radius | 60mm/ 10mm | 14 | Beeline tolerance | ≤ 2‰ | |||

| 3 | Max coil length | 1200mm | 15 | Repeatable set length error | ≤ 0.6mm | |||

| 4 | Beeline feeding axis | Journey: | 0--1200mm | 16 | Pipe end inner diameter shrinking rate | f < 20% | ||

| 5 | Speed: | 0--1000mm/sec | 17 | Length error in each cutting | ≤ 0.5mm | |||

| 6 | Precision: | ±0.05mm | 18 | End-forming part | Machining position | 2 | ||

| 7 | Spatial rotating axis | Angle: | 0--±360° | 19 | Max clamping force | 1000kg | ||

| 8 | Speed: | 0--600°/sec | 20 | Max plus force | 1000kg | |||

| 9 | Precision: | ±0.05° | 21 | Max machining depth error | < ±0.5 | |||

| 10 | Bending axis | Angle: | 0--195° | 22 | Max coaxial error | < 0.1 | ||

| 11 | Speed: | 0--300°/sec | 23 | Hydraulic motor power | 2.2KW | |||

| 12 | Precision: | ±0.05° | 24 | Hydraulic system pressure | 5-8Mpa | |||

| 25 | Integrated power | 5~8 sec/ bend | ||||||