CNC Tube Chipless Cut-Off Machine (Continuous Feeding)

Request a Quote

View All: http://oms-equipment.com

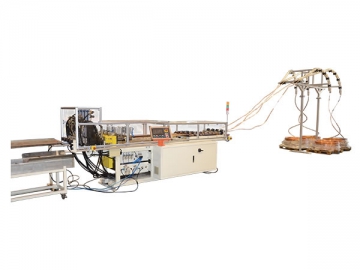

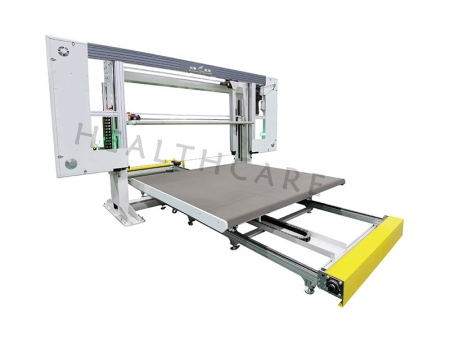

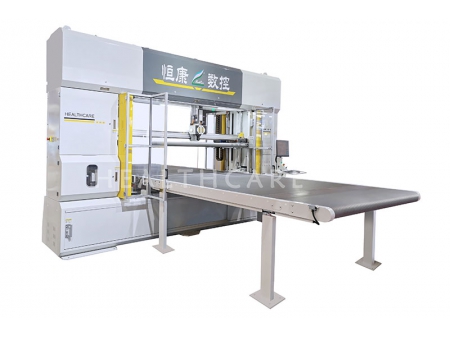

Machine drawing of the CNC tube chipless cut-off machine (continuous feeding)

The CNC tube chipless cut-off machine is used to decoil, straighten and chiplessly cut-off coils into straight coils of fixed lengths.

It is mainly used to cut the pipelines of air-conditioners, water heaters, aircrafts, automobiles, etc.

- CNC tube chipless cut-off machine (continuous feeding)

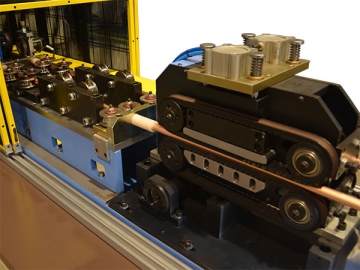

- Continuous feeding by belts for high efficiency cutting of long tubes (>3m)

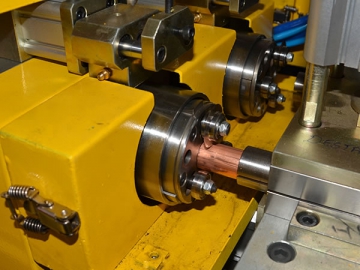

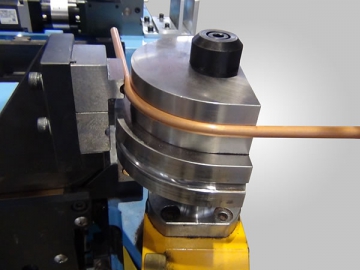

- Cutter - rotating, chipless cut

- Snapping mechanism for short tube cutting

Features:

Continuous feeding by belts, high efficiency, for cutting long tube (length>3m)

| Main technical parameters | |||||

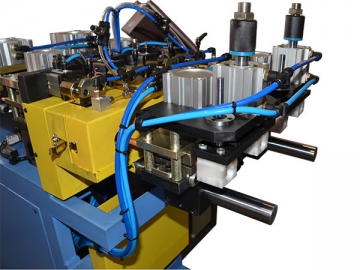

| 1 | Processing material | coil copper/aluminum tube | 7 | Feeding mode | Belt pushing, continuous feeding |

| 2 | Max processing tube OD | Ф22.225mm or7/8" | 8 | Length detection | Rotary encoder |

| Max tube wall thickness | 1.016mm | 9 | Length precision | ±2.5mm when cut length>1000mm | |

| 3 | Shrinking rate of tube end inner diameter | ≤ (Wall thickness×25%) | 10 | Feeding speed | 700mm/s (adjustable) |

| 4 | Number pf Simultaneously cutting | 2 tubes | 11 | Cutting speed | 3 sec/one time |

| 5 | power | Two power (servo feeding ) | 12 | Power supply | 220V 3 phase 60HZ |

| 6 | Minimum cutting length | 40 mm | 13 | Air supply pressure | 0.4-0.6Mpa |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos