Bag Filling and Sealing Machine

The bag filling and sealing machine is appeared as the perfect alternative to traditional manual packaging methods. This fully automatic packaging system is highly distinguished by exceptional efficiency, cost saving and automation.

Advantage

1. We manufacture our bag sealer in absolute tune with food safety standards for food production machines. In particularly, parts contacting with materials and bags are made up from hygienic materials in accordance with standards. Therefore, your products are packaged with ensured safety and hygiene at highest level.

2. Our bag filling and sealing machine involves the utilization of premade bags with ingenious patterns, flawless sealing and attractive appearance. Moreover, an extensive host of bag materials are applicable, including multi-layer composite film, single-layer PE and PP, as well as paper.

3. Incorporating with various filling equipment, this bag filler is capable of packaging all kinds of materials such as solids, fluids, sauces, powders and granules, etc.

4. The utilization of advanced Mitsubishi PLC and colorful POD demonstrates our user centric design concept. Main electric motor comes with frequency control and easy frequency setting can be realized on the color POD within certain adjustable range.

5. Featuring automatic fault detection system, this bag filling and sealing machine displays status on air supply, temperature, bag feeding and bag opening, etc. Therefore, customers are able to control coding machine, filling device and heat sealing equipment accordingly, thus minimizing production waste.

| Model | |

| Bag hanging device | Six |

| Bag material | Composite film, PE and PP, etc. |

| Bag type | Stand up pouch (with/without zipper), flat bottom bag (3 side seal, 4 side seal, handbag, zippered bag), paper bag |

| Bag dimension | W: 100 to 300mm, L: 100 to 400mm |

| Production rate | 30 to 60 bags/min (depending on material type and weight) |

| Machine weight | 1000kg |

| Power supply | Three phase, 380V, 60HZ |

| Total power | 2kW |

| Air consumption | 0.6m3/min (Provided by user) |

| Overall dimension | 1550 (L) × 1350 (W) × 1400 (H) |

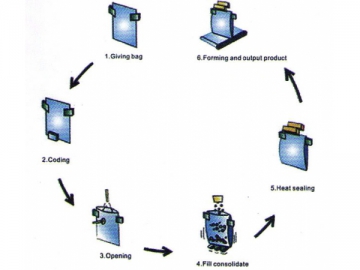

- Bag feeding

- Bag hanging

- Bag opening

- Bag filling

- Bag sealing