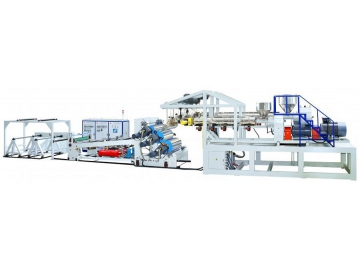

Co-Extrusion Blown Film Line

The multi-layer blown film line is equipped with the extruder with force feeding function, precision type ceramic heater, precision type air ring with double vents, horizontally rotary traction system, fully automatic surface friction type winder with double cutting double winding, computer centralized control system as well as other advanced equipment. It has been widely used in manufacture of high transparence packing films.

Different from CWHL model, this blown film line works for double or three layer co-extrusion films. The product is mainly employed for blowing plastic laminated films made of LDPE, HDPE as well as LLDPE, etc. These films have been extensively used as raw materials for packing bags of liquid, printing substrate, export product, industrial product, etc. The co-extrusion blown film has better flexibility, thus able to extend the refreshing time of the packed liquid.

The main machine of the blown film line is characterized by variable frequency control, which not only improves the stability of speed regulation but also saves electricity by 30%. The plastic film blowing machine comes with two sets of screw and barrel, as well as two sets of die head and gear boxes. The screw is constructed from 38CRMOAIA alloy steel with precision machining and nitrogen treatment. Accordingly, it has optimum hardness and can be used durably. The lifting type traction frame can provide films, large or small, with the best cooling effects.

Optional Equipment

1. Automatic Suction Machine

2. Surface Treating Machine

3. Air Compressor

4. Manual Quick Screen Changing Unit

5. Double Winding Device

6. Rotary Die Head

| Model | ||||

| Suitable Material | LDPE, LLDPE, HDPE | |||

| Length of Folded Film | 600-1000 mm | 800-1500 mm | 1000-1800mm | 1500-2500mm |

| Film Thickness | 0.002-0.2 mm | 0.002-0.2 mm | 0.05-0.2 mm | 0.05-0.15mm |

| Extrusion Output | 80-120kg/hr | 120-150kg/hr | 150-180kg/hr | 180-250kg/hr |

| Extruding Equipment | ||||

| Screw Diameter | Φ 45/50/45 | Φ 50/55/50 | Φ 55/60/55 | Φ 65/70/65 |

| Screw L/D Ratio | 28:1/ 30:1 | |||

| Screw Material | SACM-645/38 CRMOALA | |||

| Cylinder Cooling | 370W×2 | 550W×2 | 550W×3 | 550W×4 |

| Temperature Control of Plastic Cylinder | 3 groups | 3 groups | 3 groups | 4 groups |

| Extruding Motor | 18.5/22/18.5 kW | 22/30/22 kW | 30/37/30 kW | 37/45/37 kW |

| Extrusion Die Diameter | Φ 250/200 | Φ 300/350 | Φ 500 | Φ 600 |

| Temperature Control | 3groups | 3groups | 4groups | 4groups |

| Air Ring | 1group | |||

| Height Adjustable Type | 700mm | |||

| Guiding Speed | 10-65m/min | 10-65m/min | 10-65m/min | 10-60m/min |

| Width of Guiding Roller | Φ 165×1100 | Φ 165×1600 | Φ 190×2000 | Φ 220×2600 |

| Effective Guiding Width | 1000mm | 1500mm | 1800mm | 2500mm |

| Winding Motor | 10N.M | 20N.M | 30N.M | 40N.M |

| Winding Speed | 10-65m/min | 10-65m/min | 10-65m/min | 10-65m/min |

| Overall Dimension | 6.5×5.5×6.5 m | 7.5×5.8×7.5 m | 7.8×6.4×7.5m | 8.5×7.2×10M |

Note: The appearance, performance characteristics as well as technical specifications may vary without notice, owing to the consistent improvement of existing products as well as development of new functions.

Related Names

Multilayer Film Blowing Machine | Film Co-extruder | Plastic Film Extrusion Machine