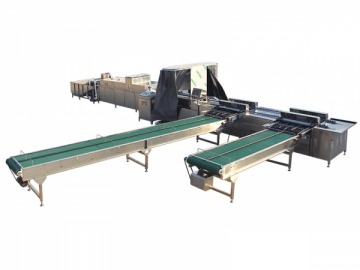

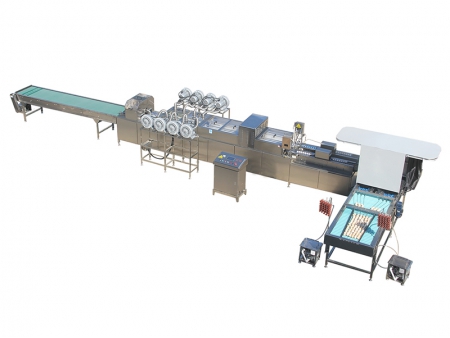

Egg Collection System

For today's poultry farms, it is essential to choose the right egg collection system that will save time and money and produce high-quality and clean eggs with a minimum number of cracked eggs. Dingtuo can meet your demands on automatic egg collectors in high reliability, ease of operation and perfect egg handling.

Our egg collection system is an ideal system to ensure a safe trip for the egg all the way from the hen to the conveyor. It comes with simple and reliable construction and provides high collection capacity. Gentle transportation minimizes egg cracking and high automation saves a large number of egg production costs.

Structural Features

1. Dingtuo's egg collection system designed for efficient poultry production consists of loading and unloading devices, egg collecting devices, conveying device, sprockets, chains, etc.

2. It is suitable for large size chicken farms, providing the functions of preventing egg cracking and reducing costs.

3. By means of conveyor belt, the egg collecting system transports eggs gently all the way from cages to the end of poultry house or transports to egg warehouse via central collection system. It comes with high automation, considerably improving productivity.

4. Used with our superior poultry cages and newly designed egg blocking device, the system ensures a large reduction of egg cracking rate.

5. The egg collector features simple structure and easy installation and operation.

- Main Machine

- Control Panel

- Egg Conveyor Belt

Main Parts Installation and Commissioning

1. Ground in the poultry house should be hardened and flattened. Degree of slope can not exceed 2°.

2. Cage stand should be flat placed. Height deviation of two cage stands is not more than 0.5mm by adjusting of foot pieces.

3. Firmly fasten the egg collector to the central part of cage stand. Fix headstock and tailstock to ground without looseness.

4. Install egg collecting belt and check whether the belt is fit with the egg support.

5. Install belt support device every other one meter, and install one at the front of tail pulley to prevent egg returning back and thus reduce cracking rate.

6. Have professional electrician carry out wiring and firmly fasten the wires.

7. Earth leakage circuit breaker has to be installed in the controller.

8. Perform test run through the control panel to confirm if there are scratch, stagnation, defection and other problems.

9. If there are problems, find out the reasons and handle them in time.

10. Finally, if the belt travel stably, ensuring uniform egg colleting, low noise (<40db) and no large shaking, the egg collection system is qualified.

- Egg Belt Clip

- Egg Support

- Egg Conveyor Belt

- Unassembled Egg Collector

Maintenance and Repair

1. Read the first part in detail before use: Safety Regulations, to avoid danger;2. Fill HL-30 gear oil of about 4L into the reducer;

3. The egg collection system can be put into work after test run. At least, the equipment collects eggs 2-4 times per day;

4. Check regularly if the belt is off tracking;

5. Check the lubrication oil of reducer once a week and add if it is not enough. Instill lubrication oil to the transmission chains;

6. Inspect the tension of chains monthly based on that middle part of the chain at most lowers by 10mm;

7. Change the oil of reducer once a year;

8. Add grease to all bearing seats once a month;

9. Before start up, check whether there are impurities on the egg belt and clean it up if there are;

10. To ensure normal use and extend service life, please blow away dirt on the machine using air blow gun every day. Do not use broom to clean the belt and do not use water to wash the machine.

11. Handle problems in time;

12. Keep the check record so as to find out fault causes and ask for after-sales service;

13. Installation, adjustment, maintenance and repair should be carried out under power off condition.

14. Machine damage, even personal injury will possibly be caused by operation not complying with the rules.

| Faults | Reasons | Solutions |

| Reducer generates large noise | 1. Gear wear 2. Bearing damage 3. Lack of lubricating oil | 1. Change 2. Change 3. Add lubricating oil |

| Motor is overheating | 1. Unstable voltage 2. Phase-deficient running 3. Heavy load | 1. Find out the reason 2. Inspect 3. Increase clean times |

| Belt runs but eggs does not go along with it | 1. Ground is not flat 2. Cage height is uneven 3. Eggs are not cleared up in time | 1. Relay the ground 2. Adjust foot bolts to level the cage 3. Clear up in time |

| Equipment doesn't work | 1. Motor is turned off 2. Traction rope or belt is too loose 3. Motor fault | 1. Check circuit 2. Tension the rope or belt 3. Change motor |

| Belt is off tracking | 1. Eggs are not cleared up in time 2. Tail pulley is not at the right position 3. Idle running for a long time | 1. Clear up eggs in time 2. Adjust the tail pulley 3. Reduce idle running time (by 45m/10min.) |