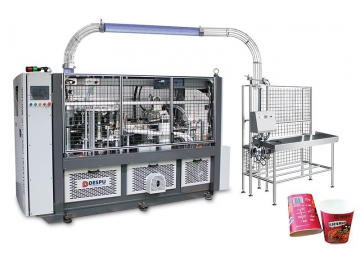

Single PE Coated Paper Bowl Forming Machine MG-Q35

Paper bowl machine, salad box making machine, automatic disposable coffee cup making machine, paper cup machine for Korean, hot sale CE certificate cup making machine, paper cup machine price

This piece of single PE coated paper bowl former is developed based on a deep understanding of modern paper bowl making techniques and market demands. It is the first choice for producing an entire array of disposable bowls, especially single PE coated paper bowls. The paper bowl forming instrument also draws lots of attention from both domestic and foreign clients for its easy operation, stable properties and high economic benefits. Not only that, a series of processes is fulfilled by this machine, such as paper feeding, heating, sealing, lubricating, knurling and more.

Detailed Information of Paper Bowl Forming Equipment

Paper bowl size: 20-50oz (mold exchangeable), height up to 125mm

Paper material: 140-320 GSM one-side PE coated paper

Production capacity: 35-45 pcs/min

Power Source: 220V/380V 50Hz

Total Power: 6KW

Total Weight: 2500KG

Package Size: 2800mm*1200mm*1600mm

Note: Customized service is available

Main Advantages of Paper Bowl Maker

Daily cleanliness and maintenance of this product is convenient and easy because of the dismountable housing.

-

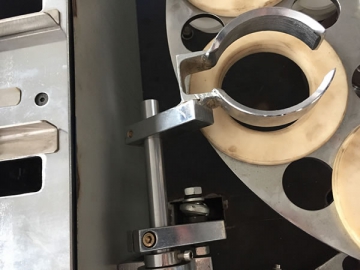

The stretchable knife realizes even wrinkles at the bottom of bowl, increases the sealing performance and decrease leakage rate.

The stretchable knife realizes even wrinkles at the bottom of bowl, increases the sealing performance and decrease leakage rate. -

It is this patented bottom rolling device that offers 5 times embossing force of traditional equipment. That’s why paper products produced by our firm have clear and uniform patterns.

It is this patented bottom rolling device that offers 5 times embossing force of traditional equipment. That’s why paper products produced by our firm have clear and uniform patterns. -

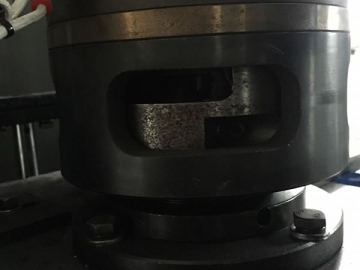

All molds are produced by CNC machines in order for uniform specifications.

All molds are produced by CNC machines in order for uniform specifications.

-

The alarming system is very functional. It will send an alert when bowl bottom shortage or accumulation occurs.

The alarming system is very functional. It will send an alert when bowl bottom shortage or accumulation occurs. -

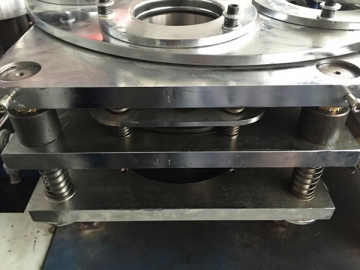

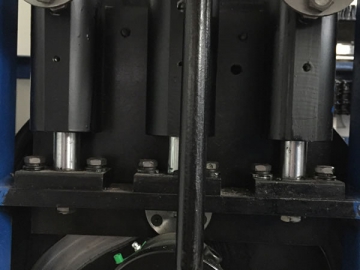

Three strong shafts and two springs are utilized for high stability and strength.

Three strong shafts and two springs are utilized for high stability and strength. -

A machinery arm is used to pick up dropped cups.

A machinery arm is used to pick up dropped cups.

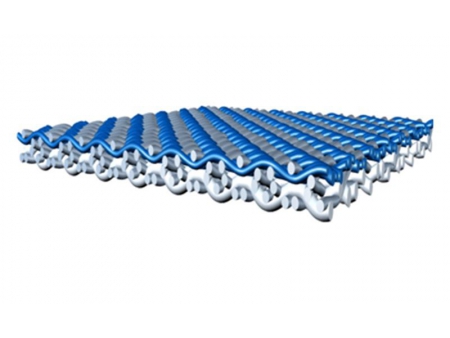

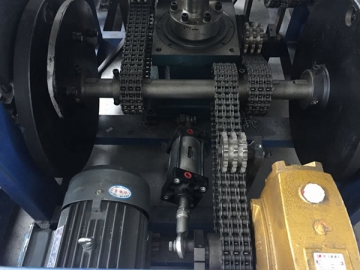

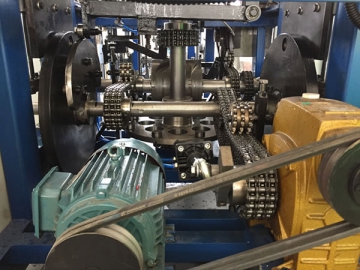

There are two types of transmission system to choose

-

Traditional gearbox and chain type is relatively cheap

Traditional gearbox and chain type is relatively cheap -

The modern cam and chain transmission type is more durable and stable. It has been widely accepted in recent years.

The modern cam and chain transmission type is more durable and stable. It has been widely accepted in recent years.

Service

Our company provides unsurpassed and consistent service for clients. We can help you resolve problems via e-mail, telephone, video, etc. For better service, our customer service staff will be online around the clock. If needed, we can assign professional engineers or technicians to your company.

All machines will be packaged with wooden cases.

Ruian Mingguo Machinery Co., Ltd.

Tel.:

Fax: 86-577-65012527