Steel Wire Reinforced PVC Hose Extrusion Line

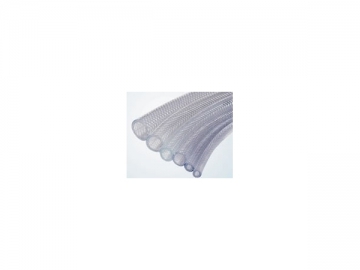

Steel wire reinforced PVC hose is made up of the spiral steel wire incorporated within the wall of flexible PVC tubing. Glass-like clarity makes this hose a real eye-catcher. Resilient and non-toxic, the hose often operates within an allowable temperature range of between -10℃ and 65℃.

As the popularity of steel wire reinforced PVC hose continues to grow, PVC pipe manufacturers are quickly moving to the design and production of wire reinforced PVC hoses. This creates high demand for our reinforced PVC hose extrusion line.

Years of experience in the production of plastics extrusion equipment allows us to develop high-quality extrusion lines that use one or multiple layers of steel wire, glass fiber, or polymer fiber to strengthen PE pipes. The resultant reinforced fiber is able to handle high pressure applications.

During the construction of reinforced hoses, special adhesives are used to improve the hose’s resistance to water and oxygen. The hose shows excellent integrity with proper strength, softness, rigidity, fusibility, and maximum resistance to creep and crack. Popular uses of the steel wire reinforced PVC hose are in the transportation of high-pressure, flammable gases and liquids as well as in the removal of liquid impurities. The hose is mainly delivered to machinery, chemical, construction, irrigation, and vacuum equipment industries.

Features

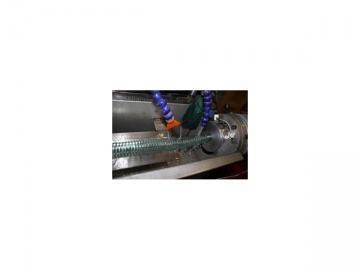

1. This steel wire reinforced PVC hose extrusion line is incorporated with a high-efficiency extruder which ensures high extrusion quality and productivity.

2. Equipped with a coil winding machine, the extrusion line is able to make tight and uniform windings of steel wires.

3. The resultant pipes exhibits glass-like clarity with the steel wire evenly wound around the tube wall in a pre-set length.

4. Main electric parts are of well-known imported brands which ensure stable, reliable functioning of the whole extrusion unit.

5. One-piece design of push buttons allows for ease of operation. Even first-time operators would learn quickly how to use the extrusion equipment.

| Model No. / Parameter | Hose Diameter Range (mm) | Extruder Model No. | Production Rate (m/min) | Productivity (kg/h) | Installed Capacity (Kw) | Dimension (m) | Weight (t) |

| 12-25 | LSJ45/25 | 1-10 | 40 | 30 | 12×3.6×2.5 | 6.4 | |

| 20-50 | LSJ65/25 | 1-8 | 50 | 42 | 15×3.6×2.5 | 7.1 | |

| 50-102 | LSJ90/25 | 0.5-6 | 70 | 60 | 18×3.6×2.5 | 9 | |

| 75-150 | LSJ120/25 | 0.5-4 | 90 | 80 | 20×3.6×2.5 | 10.5 |