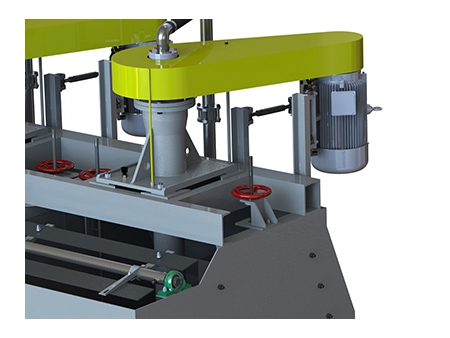

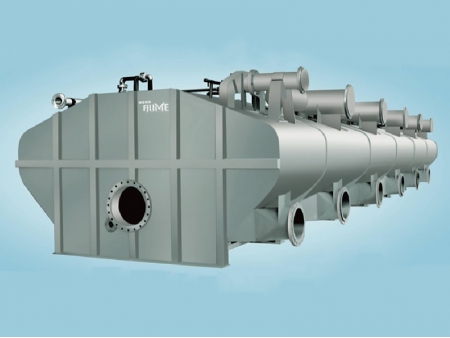

Forced Air Flotation Cell

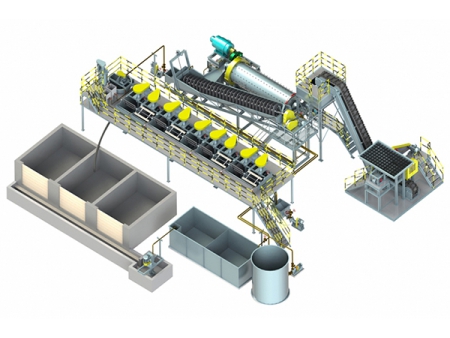

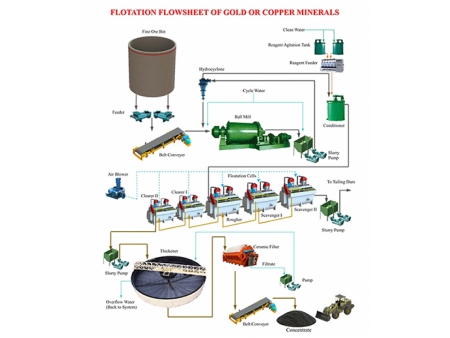

Flotation cell (froth flotation) is receiving an ever-increasing application in mineral processing and chemical engineering industries. The flotation cell is applied as a concentration machine by large, medium, and small size mineral processing plants for the recovery of metal minerals, including gold, silver, copper, lead, zinc, nickle, manganese, iron, molybdenum, tungsten and non-metallic minerals, including barite, quartz, graphite, feldspar and fluorspar.

Working Principle

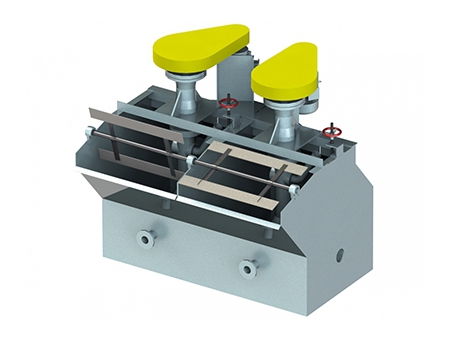

When the impeller starts to rotate, the ore slurry is sucked from the bottom of the cell into the interval between the impeller blades. In the meantime, an external blower of this forced air flotation cell supplies low-pressure air through the hollow shaft and the air dispersion. The ore slurry comes in contact with the air between the blades. The mixture of slurry and air is discharged out of the upper section of the blades and enters the flotation cell after the stator surrounding the impeller reduces the slurry vortex. The bubbles then rise to the stablization region and after the concentration process enters the froth launder that collects and transports the froth. Some ore slurry flows to the lower section of the blade and becomes mineralized froth again after the agiatation of the blade. The remaining slurry ore will flow to the next cell and finally become tailings.

- The XCF flotation cell and the KYF flotation cell share similarities in structure and property. But the XCF type has a stator surrounding the impeller that can create a negative-pressure area for self-aspiration of ore slurry. The power consumption is slightly higher.

- The XCF flotation cell and the KYF flotation cell can be combined as a flotation cells set.

| Model | Effective Volume (m3) | Capacity (m3/min) | Impeller Diameter (mm) | Impeller Speed (r.p.m) | Inflation pressure (Kpa) | Air Inflation Flow (m3/m2.min) | Agitaor Power (kW) | Scraper Power (kW) |

XCF-1 | 1 | 0.2-1 | 400 | 358 | ≥12.6 | ≤2 | 5.5 | 1.1 |

XCF-2 | 2 | 0.4-2 | 470 | 305 | ≥14.7 | 7.5 | ||

XCF-3 | 3 | 0.6-3 | 540 | 266 | ≥19.8 | 11 | 1.5 | |

XCF-4 | 4 | 1.2-4 | 620 | 225 | ≥19.8 | 15 | ||

XCF-8 | 8 | 3.0-8 | 720 | 175 | ≥21.6 | 22 | ||

XCF-10 | 10 | 4-10 | 720 | 192 | ≥21.6 | 30 | ||

XCF-16 | 16 | 4-16 | 860 | 160 | ≥25.5 | 37 | ||

XCF-24 | 24 | 4-24 | 945 | 166 | ≥30.4 | 55 | ||

XCF-30 | 30 | 8-30 | 1020 | 138 | ≥31 | 55 | ||

XCF-38 | 38 | 10-38 | 1050 | 141 | ≥32 | 75 | ||

XCF-40 | 40 | 10-40 | 1050 | 141 | ≥32 | 75 | ||

XCF-50 | 50 | 10-40 | 1200 | 125 | ≥35 | 90 |

| Model | Effective Volume (m3) | Capacity (m3/min) | Impeller Diameter (mm) | Impeller Speed (r.p.m) | Inflation Pressure (KPa ) | Air Inflation Flow (m3/m2.min) | Agitator Power (kW) | Scraper Power (kW) |

KYF-1 | 1 | 0.2-1 | 340 | 281 | ≥12.6 | ≤2 | 4 | 1.1 |

KYF-2 | 2 | 0.4-2 | 410 | 247 | ≥14.7 | 5.5 | ||

KYF-3 | 3 | 0.6-3 | 480 | 219 | ≥19.8 | 7.5 | 1.5 | |

KYF-4 | 4 | 1.2-4 | 550 | 200 | ≥19.8 | 11 | ||

KYF-8 | 8 | 3.0-8 | 630 | 175 | ≥21.6 | 15 | ||

KYF-10 | 10 | 4-10 | 630 | 192 | ≥2106 | 22 | ||

KYF-16 | 16 | 4.0-16 | 740 | 160 | ≥25.5 | 30 | ||

KYF-24 | 24 | 4.0-24 | 800 | 166 | ≥30.4 | 37 | ||

KYF-30 | 30 | 8-30 | 880 | 135 | ≥31 | 45 | ||

KYF-38 | 38 | 10-38 | 880 | 138 | ≥32 | 55 | ||

KYF-40 | 40 | 10-40 | 950 | 135 | ≥32 | 55 | ||

KYF-50 | 50 | 10-40 | 1030 | 128 | ≥35 | 75 |