Professional solution provider of sewage treatment

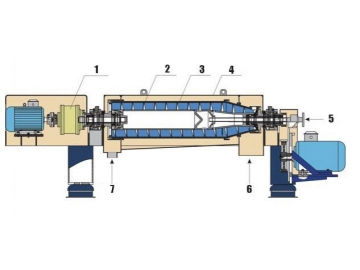

The horizontal decanter centrifuge is mainly used to separate solids and liquids in different sewage, such as, residential wastewater, industrial wastewater, chemical wastewater, and wastewater in food, pharmacy, mining, petrochemical and many other industries.

- differential mechanism

- screw

- drum

- cover shell

- feed inlet

- solid outlet

- liquid outlet

Sewage from the feed inlet enters the drum through the spiral discharge window. Under the action of centrifugal force produced by high-speed rotation, the particles with high specific gravity and water content are deposited on the inner wall of the drum, and then by the spiral blade moving relative to the drum at a certain differential speed, the solid particles are continuously pushed to the slag discharge port. The treated sewage finally flows through the liquid outlet to rotate the drum. The relative motion between the helix and the drum is realized by a differential, and the difference is controlled by the auxiliary motor, thus separating the solid and the liquid successfully.

| model | Main technique parameters | Power of motor(Kw) | Size (mm) | Total weight(Kg) | Differential type | |||||

| Diameter (mm) | Length (mm) | Speed of rotation(r/min) | Separation factor (g) | Capacity (m³/h) | Power of main motor (Kw) | Power of auxiliary motor (Kw) | ||||

| WT250×1000 | 250 | 1000 | Max4700 | Max3090 | 0.5~3 | 11 | 3 | 2805×835×1055 | 1050 | Planetary Gear |

| WT360×1380 | 360 | 1380 | Max4200 | Max3550 | 3~10 | 22 | 7.5 | 3622×960×1282 | 2500 | Planetary Gear |

| W360×1380 | 360 | 1380 | Max4200 | Max3550 | 3~10 | 22 | 7.5 | 2914×1728×993 | 2250 | Planetary Gear |

| WT450×1600 | 450 | 1600 | Max3600 | Max3260 | 5~30 | 37/(45) | (15)/11 | 4088×1216×1519 | 3500 | Planetary Gear |

| W450×1600 | 450 | 1600 | Max3600 | Max3260 | 5~30 | 37/(45) | (15)/11 | 3244×1878×1070 | 3300 | Planetary Gear |

| WT500×2000 | 500 | 2000 | Max3500 | Max3425 | 10~35 | 45/(55) | (15)/11 | 4164×1351×1589 | 4050 | Planetary Gear |

| WT550×1900 | 550 | 1900 | Max3300 | Max3351 | 15~40 | 55/(75) | 15/(18.5) | 4464×1351×1589 | 5150 | Planetary Gear |

| W550×1900 | 550 | 1900 | Max3300 | Max3351 | 15~40 | 55/(75) | 15/(18.5) | 3477×1956×1204 | 5030 | Planetary Gear |

| WT650×2650 | 650 | 2650 | Max2400 | Max2100 | 20~60 | 110 | (22)/18.5 | 5656×1350×1743 | 8600 | Planetary Gear |

| WT720×2800 | 720 | 2800 | Max2200 | Max2000 | 30~70 | 132 | (30)/22 | 6439×1543×1998 | 10100 | Planetary Gear |

| WT800×2800 | 800 | 2800 | Max2200 | Max2200 | 40~90 | 132 | (30)/22 | 6439×1623×2038 | 11800 | Planetary Gear |

differential mechanism

Drum

The drum adopts inverted cup drum and lower feeding mode, whose advantage is to shorten the length of the spindle and the solid residue can be discharged more quickly.

Japanese NSK bearing

Drum