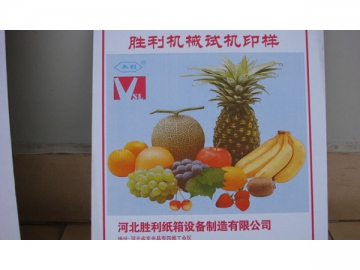

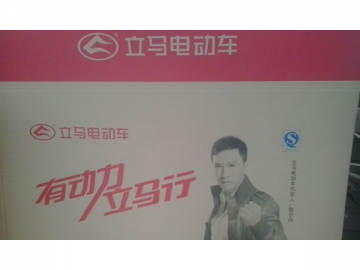

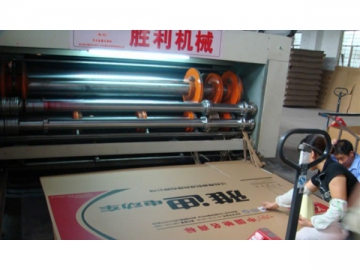

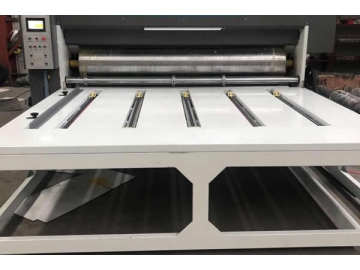

Flexo Printer Slotter Die Cutter Machine, YFQ-Ⅱ Series

Main Characteristics of Flexo Printer Slotter Die Cutter

1)Name brand low voltage electric parts.

2)Main bearings are produced by LYC, ZWZ and Harbin

3)Main gears undergo a high frequency quenching process and grinding to ensure high precision transmission.

| Parameter name | Unit | Specification | ||

| YFQ- Ⅱ 1370X | 2200 2500 2800 3000 | |||

| Inner size of machine | mm | 2400 2700 3000 3200 | ||

| Design speed | Pcs/min | 80 | ||

| Max paperboard size | mm | 1370 | 2200 2500 2800 3000 | |

| Mini paperboard size | mm | 400 | ||

| Max printing area | mm | 1300 | 2040 2340 2640 2840 | |

| Maxi paperboard thickness | mm | 11 | ||

| Over print precision | double color | mm | ± 0.5 | |

| three color | mm | ± 0.75 | ||

| four color | mm | ± 1.0 | ||

| Parameter name | Unit | Specification | ||

| YFQ- Ⅱ 1700X | 2200 2500 2800 3000 3500 | |||

| Inner size of machine | mm | 2400 2700 3000 3200 3700 | ||

| Design speed | Pcs/min | 60 | ||

| Max paperboard size | mm | 1700 | 2200 2500 2800 3000 3500 | |

| Mini paperboard size | mm | 500 | ||

| Max printing area | mm | 1630 | 2040 2340 2640 2840 3340 | |

| Maxi paperboard thickness | mm | 11 | ||

| Over print precision | double color | mm | ± 0.5 | |

| three color | mm | ± 0.75 | ||

| four color | mm | ± 1.0 | ||

1)Chain feeding

2)Speed adjustment table for indication and operation.

1)Metal anilox roller with optional ceramic roller upgrade.

2)High quality rubber roller.

3)Touch screen interface to perform phase adjustments and other operating procedures.

1)Touch screen for electronic adjustment

2)Carton box size is manually adjusted.

3)Electronic phase adjustment.

1) Duramax rubber cushion designed in Taiwan ensures a long useful life.

2) Touch screen for operation and phase adjustment.

3) Mechanical cam structure for precise cuts every time.

4) Electronic phase adjustment.

1)Protection devices are installed to protect the operator.

2)The back baffle position is manually adjusted.

3)Chain driven.

4)1600mm stack height.

Related names:

Fiberboard auto stacker | Corrugated cardboard flexo printer | Cardboard sheet die cutting machine