Aluminum Billet Pre-heat Furnace for Extrusion - Single Billet

Description

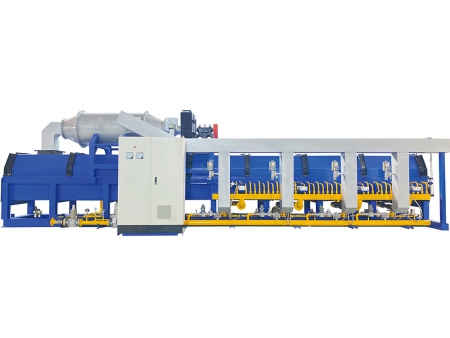

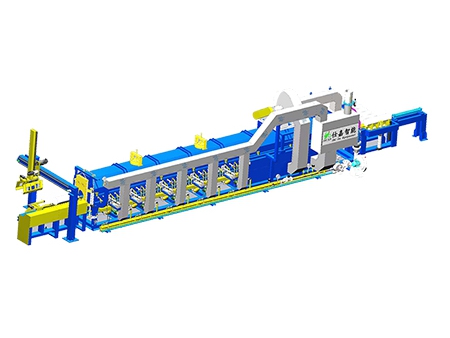

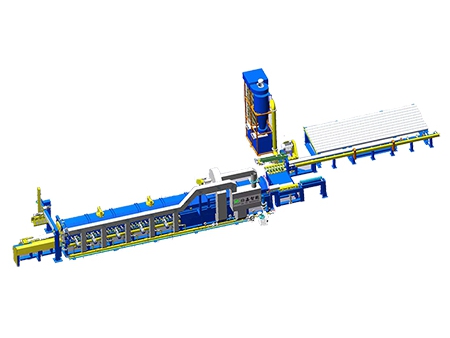

Single billet furnace is typically used for preheating individual aluminum billet or log to the desired temperature for extrusion.

- Single billet furnace has three zones, i.e., soaking, preheating and heating zones. Soaking zone enables that every aluminum billet has temperature uniformity of ±9℃ when it fed-out from soaking zone. Preheating zone is characterized by equipping with an additional air blower for efficient preheating performance, which exploits hot gases exhausted from heating zone to impinge the aluminum billet that enters pressure-controlled furnace chamber.

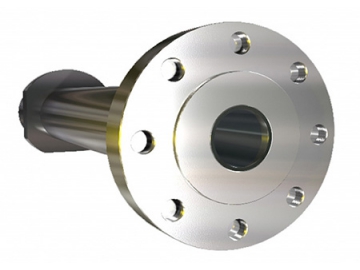

- Unique nozzle design helps combustion to be optimal, enhancing temperature uniformity and thermal efficiency.

- Due to its rapid heating speed, after being heated by 30min in usual, aluminum billet can be transferred into extrusion process.

- With features of high automation and flexibility, this single billet furnace is suitable for extruding of a variety of industrial profiles with small amount.

- Can be equipped with auxiliary equipment, such as billet manipulator.

Video

Technical parameters:

| Billet diameter | Heating time | Heating speed | Energy consumption | Power |

| Φ90-Φ152mm | ≦30min | 90 S/billet | ≦35m³/T.Al | 30kw |

| Billet diameter | Heating time | Heating speed | Energy consumption | Power |

| Φ178-Φ203mm | ≦30min | 120S/ billet | ≦30m³/T.Al | 50kw |

| Billet diameter | Heating time | Heating speed | Energy consumption | Power |

| Φ228-Φ320mm | ≦30min | 120S/ billet | ≦25m³/T.Al | 65kw |

| Billet diameter | Heating time | Heating speed | Energy consumption | Power |

| Φ330-Φ406mm | ≦30min | 150S/ billet | ≦25m³/T.Al | 110kw |

Recommendations

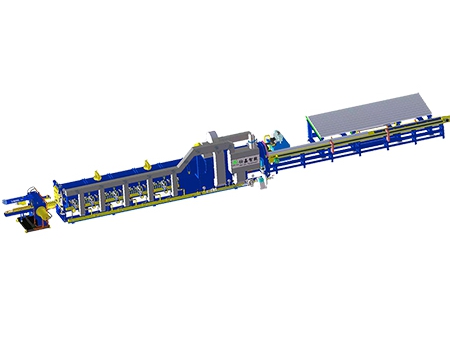

single billet heating furnace hot shear

single billet heating furnace hot shear single billet heating furnace hot saw

single billet heating furnace hot saw short billet heating furnace

short billet heating furnace cold saw single billet heating furnace

cold saw single billet heating furnace

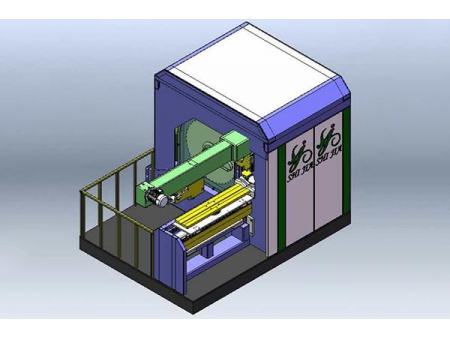

Construction

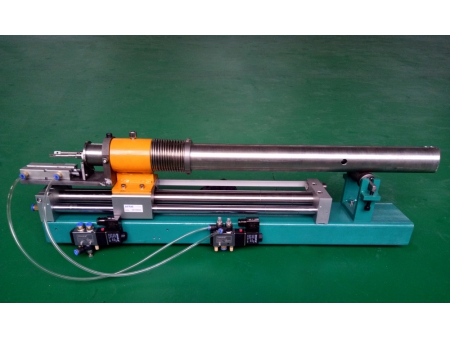

Temperature measurement system

The temperature measurement system is used for measuring temperature of the aluminum billets, which is designed by ourselves, so it is in prefect compatible with the preheat furnace.

As the aluminum extrusion presses used by customers feature different production capacity, the diameter of the aluminum billets might also differ, the aluminum billets with different thickness, however, vary in heating time. For the thicker aluminum billets, for example, we will change the heating zones to reduce its heating time. We are able to customize various aluminum heating furnaces according to various production capacity of the aluminum extrusion press.