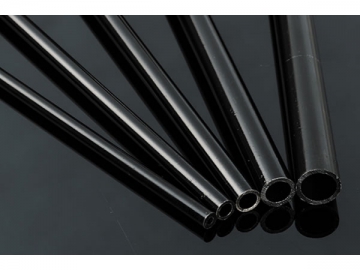

High Pressure Fuel Injection Steel Tube

Steel Tube for High Pressure Fuel Injection / Compression Ignition Common-Rail High Pressure Fuel Pipe / High Pressure Steel Pipe / Automotive Steel Pipe

We utilize ISO-8535 standards to produce our compression ignition common rail high pressure fuel pipes. The raw material SDY1800 is nearly the same grade as German grade DSG1800.

This material has been jointly developed by us and Baosteel, with a normal working pressure of over 1600kg or 1800kg.

The tolerance for OD and ID can be /- 0.5mm, with a core quality reaching Q grade levels. Due to that, these high pressure steel pipes can replace other international brand tubes.

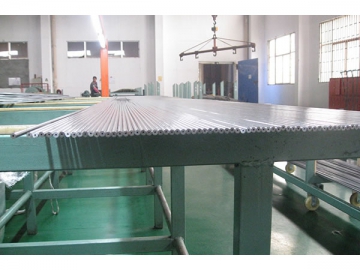

Process Description

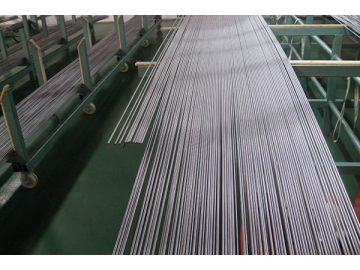

Using German standard quality steel as the raw material (ST35, ST37.4, and ST52.4), and a fine drawing, there is no need for an oxidation bright heat treatment (NBK state), and the testing is carried out in non-destructive methods.

Selection Criteria:

ISO8535-1 (compression ignition engine with a high pressure pipeline steel standard), ISO404 1992 (steel and steel products in general technical requirements), ISO6892 1984 (metal tensile test)

Main Features

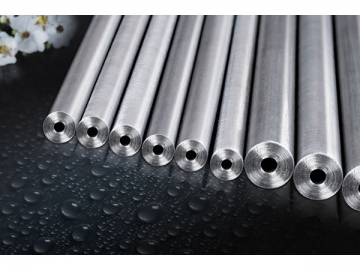

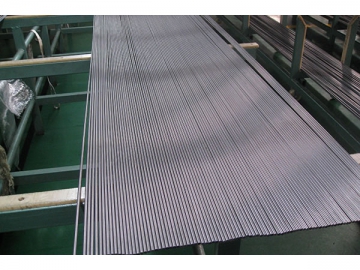

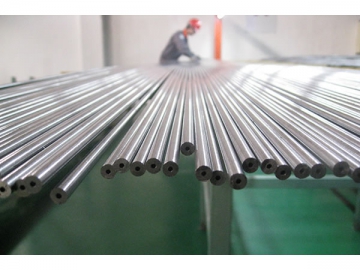

These high precision steel pipes feature an outstanding accuracy and excellent finish. After the heated pipe’s outer wall undergoes an oxide layer treatment, the inner wall needs to undergo a cleaning process using high pressure washing equipment and rust resistant oil coating for steel processing. The total impurity content is ˂1.5mg/m. The maximum particle size is 8 (less than 0.2mm). Using steel to withstand high pressure and cold deformation, we can make pipes in a variety of complex deformation and mechanical processing. The steel pipe colors are gray and white. The diameter, and size of the whole tolerance is ±0.05m and a high Q cavity surface quality level. The normal working pressure is 2,000 kg, though testing pressure has reached 6,000kg with no deformation. The steel pipe is cold formed 180 degrees around a rod with the same outer diameter. The surface is also smooth, with no cracks.

Main Purpose

Sheng Ding Yuan produces compression ignition engines with a high pressure tubing series of technical indicators that work in full compliance with international brand standards for steel pipes and tubing. These pipes can completely replace imported products to reduce costs for customers.

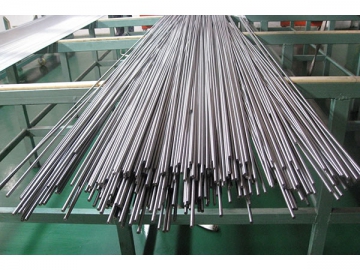

How do we ensure the quality of these automotive steel pipes?

1. We use high quality raw materials. All raw materials are supplied from internationally known steel plants.

2. Each batch of raw material is checked for both chemical and mechanical properties, according to specifications.

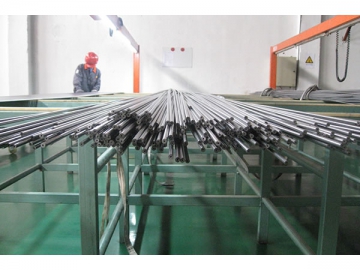

3. During the cold drawing process, our inspectors check every bundle three times: once at the beginning of the process, once during the middle, and finally, at the end of the cold drawing process.

4. During the final heat treatment, every bundle has the surface checked, as well as mechanical properties through sampling.

5. Non-destructive testing machinery and manual inspection ensure the 100% quality rate.