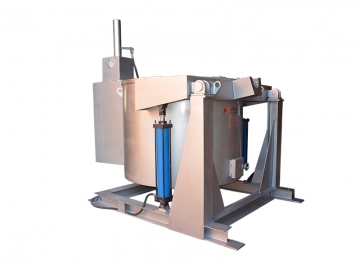

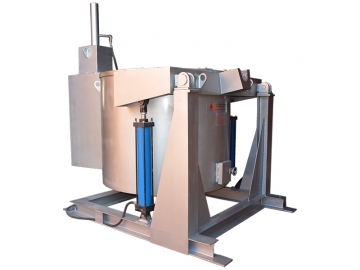

Melting Furnace, Tilting Type

Here you will find a high quality, cost effective aluminum melting solution. It is a tilting type melting furnace with a capacity of about 20t. The foundry equipment is constructed from double-layer heat insulating bricks, double-layer high alumina refractory bricks, refractory castables and one layer of fiber felt. Furnace wall thickness reaches about 500mm.

Structural Features

1. Hearth of the industrial furnace is built using 10# I-beams on which a layer of 10mm thick steel plate is laid. Coated by 8mm thick steel plate and reinforced by 10#, 12#, 14# and 25# U-steels by welding, the melting furnace comes with superior heat insulating performance, and provides exceptional robustness and durability. (Note: the 8mm thick steel plate is GB327 - 88 A3 plate manufactured by Shaogang Group and Wuhan Iron and Steel Group)

2. The furnace body features complete welding construction. It is welded from 8mm thick Q235A steel plates and rolled steels. Stiffer plates are mounted at all mechanical and thermal stress points to achieve a heavy duty steel component with reasonable stiffness and strength, so that it can become a structure with less stress, deformation, and uniform and distributed force. This can meet the requirements of thermal expansion and stress.

3. To ensure convenience for drossing and mixing (with no blind corners), the aluminum casting furnace is designed with a tilting door that is engineered from steel plates, ensuring excellent sealing and no deformation. It is normal that refractory castables have shrinkage fractures, and it is not a problem provided the molten aluminum will not be leaked.

4. Furnace door's up and down movement is driven by a gear motor. It is equipped with guide and clamping devices at two sides, ensuring that there is no friction between the door and door frame. The sprocket wheel is designed by taking absolute safety into account. In addition, when the door is closing, it has no vertical displacement and it comes with excellent sealing with the frame when it is closed.

Advantages of the Tilting Melting Furnace

1. Excellent Thermal Performance: Rapid melting, high thermal efficiency and less fuel consumption per unit output.

2. Great Maneuverability: It is convenient for operators to adjust furnace temperature, pressure and furnace atmosphere. Feeding and mixing are also easy to operate.

3. High Safety and Eco-Friendliness: Low noise, superior sealing performance, perfect operating environment. It is totally secured in ignition, burning and flameout process.

| Capacity | 20T 5% |

| Temperature difference | ±5 ℃ |

| Furnace chamber temperature | 1050 ℃ /max |

| Discharging port (offered by customer) | 1 piece |

| Furnace door lifting | Electric |

| Furnace lining materials | |

| Hearth and door slope | 230mm high quality high alumina bricks 50mm fine river sand 170mm high alumina aggregates |

| Side furnace wall above fluid level and below 300mm | 230mm superior high alumina bricks 230mm light weight heat insulating bricks 20mm alumina silica fiber felt |

| Upside furnace wall | 230mm superior high alumina bricks 230mm light weight heat insulating bricks 20mm alumina silica fiber felt |

| Furnace roof | 230mm superior high alumina bricks (arch roof) 20mm alumina silica fiber felt 60mm high alumina aggregates |

| Furnace door | 175mm insulating castables 75mm alumina silica fiber felt |

Scope of Supply (Furnace door counter weight and furnace foundation are not included)

1) Furnace body: including

1.1 Steel components

1.2 Refractory materials

2) Furnace door and drive mechanism: including:

2.1 Door steel component

2.2 Refractory materials

2.3 Heat resistant iron castings

2.4 Heat resistant seals

2.5 2.2KW pin-cycloid reducer

2.6 Sprocket wheel

2.7 Chain and related connectors

2.8 Sprocket shaft

2.9 Transmission shaft

2.10 Bearings (DIP GROOVE, PLLLOW BLOCK, etc.)

2.11 Limit switch and attachment

2.12 Button station

2.13 Furnace door guide mechanism

2.14 All fasteners