Auxiliary Machinery

This simple slitting cutting machine line includes an uncoiler, feeding guide, slitting machine, cantilevering separating, tension control board, console and general electrical equipment.

Electrical Source: 380V/50Hz/3Ph2 (or depending on local requirements)

Speed of line: 0-30m/min.

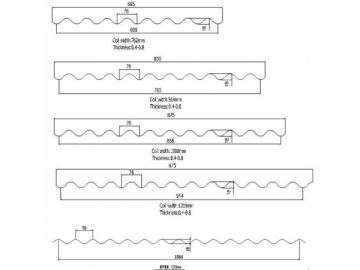

Our machine uses galvanized steel sheets, colored armor plates or aluminum plates as the material plate.

Controlled by computer: The PL display makes operation easy, and ensures a steady operation that makes the machine reliable, durable and maintenance free.

We can customize the design and fabrication on this machine according to specific requests of customers.

Application: The bending machines is used for bending roofing ridge caps, roof flashings, gutters, side walls, valleys, counter flashings, side flashings, and box barge cover.

Raw material thickness: 0.3-0.8mm

Raw material width and length: according to customer's request

Working speed: 10000-12000mm/min ( adjustable)

Total Motor Power: 2.2 Kw

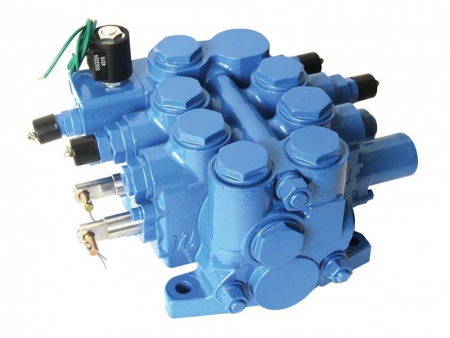

The hydraulic uncoiler is the specific machine for uncoiling metal materials. There are three or four rake fanning strips, which are connected by a dovetail groove then installed on the mandrel.

The end of the fanning strip has a radial slide installed that is capable of opening and shrinking in the radial direction in case it moves to the shaft.

The stacker for roll forming machines can carry out delivery, loading, stacking, and output automatically and as well as functions as an ideal matching machine. In order to save labor costs, it works best with a hydraulic uncoiler, and a colored steel mold machine in order to form a complete production line.