Barrel Corrugator

Technical Specification

Length of the Sheet: 4267. Max ( 20-0)

Width of the Sheet: 750/914/1000/1250( 25-10)

Thickness Range of Sheet: 0.12mmTo0.4 mm

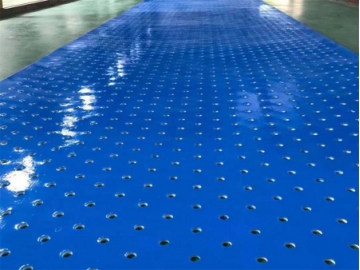

Material to be Corrugated: Full Hard, Semi-Hard, Soft Galvanized Sheets, Alu-Zinc Alloy & Ppgi Sheet

Drive: 15-22kw, AC, For Type A 3 Phase (220V-240V)

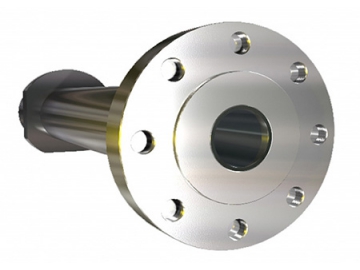

O.D. Of Corrugation Rolls: 380 mm (25 Rods)

O.D. Of Pinch Rolls: 317 Mm.

Corrugation Parameters: As per 3316 to JIS-SGCH –1987.

Production Capacity: 1.5-18 Meters per Minute. (one sheet at a time)

Weight: About 5.8 Ton

Size: About 5700×2015×1650 mm

Characteristics

1. AC. motor of power 15 -22kw.

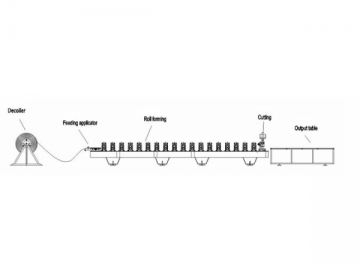

2. The corrugation machine is driven by an AC Motor through a gear reduction drive train.

3. The pinch roll assembly is driven by a chain and sprocket drive arrangements through both the corrugating rolls.

4. A tension meter arrangement is fixed on the housing to tighten the chains. This arrangement is provided to avoid the slag in the chain due to screw down operation.

5. A feed table is provided with gauge blocks to adjust the width of the sheets. This table is mounted on two brackets attached to the housing at both the sides. This table slides on an entry table.

6. The movement of the feed table is achieved by the crank & levers. The crank is mounted on the bottom corrugating roll.

7. An entry guide pipe is placed in between the entry table and the housing, in order to provide the entry of sheet into the corrugating rolls along the pass- line.

8. An auxiliary table is placed between the corrugating roll assembly and the pinch roll assembly for the proper entry of the corrugated sheets into the pinch roll assembly.

9. An exit table is provided for removing the finished corrugated sheets.

10. The screw down is for increasing/decreasing the number of crests formed on the sheets.

11. A screw down is for adjusting the gap between the pinch roll assembly and for maintaining the proper flatness on the crests of the corrugated sheets as well as to obtain the required width.

12. Gears are provided at both the ends of top and bottom corrugation rolls to adjust and keep the crests centered.

For manufacturing of barrel type corrugation machine

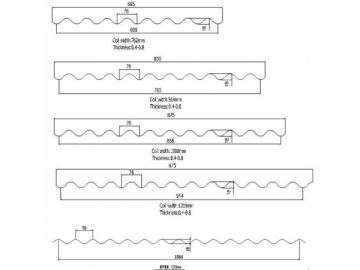

The final product (18-76 corrugated roof) produced with this machine should have the following parameters:

| Thickness of base Metal (mm) | Breadth (width before corrugation) | Length | Corrugation depth | Corrugation Pitch | ||||

| Nominal (mm) | Tolerance (mm) | Nominal (mm) | Tolerance (mm) | Nominal (mm) | Tolerance (mm) | Nominal (mm) | Tolerance (mm) | |

| 0.12-0.47 | 750-1200 | 25 -10 | Max. 4267 | - 20 0 | 18 | ± 1.5 | 76 | ± 2 |