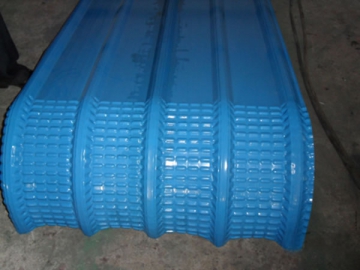

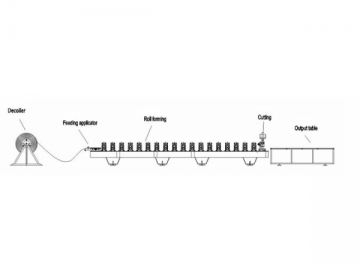

Roof Panel Curving Machine

Main Specifications

Raw material thickness: 0.3-0.8mm

Raw material width and length: according to customer's request

Working Speed: 10000-12000mm/min (adjustable)

Total Motor Power: 2.2 Kw

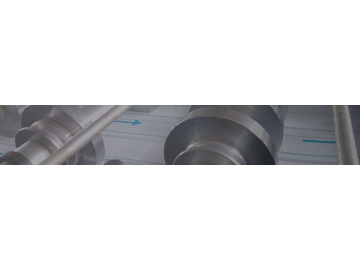

Roller material: High grade 45# forged steel, surface polished and coated with 0.05mm thickness hard chrome

Shaft material: high grade 45# Steel with Diameter 75mm

Cutting Blade: Cr12 mold steel with quenched treatment

Control: PLC computer control (frequency conversion)

Curving radius: 500mm

Our Advantages

High Quality

Reliable

Durable

Reasonable price

Excellent after sales service

1 year warranty

More than 18 years of experience

| Items | Specifications | Remarks | |

| Roll forming machine | |||

| Material of coil | Material thickness | 0.3 - 1.0 mm | |

| Material width | 1000mm | ||

| Forming system | Rolling speed | 12-15m/min(not include cutting time) | |

| Roller stations | 5PCs | ||

| Rollerm aterial | 45# forge steel, coated with chrome | ||

| Shaft material and DIA | 75mm , material is 45# forge steel | ||

| Maim motor power | 4kw | ||

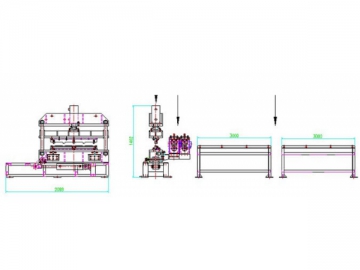

| Packing information | size of the machine | 1700×1300×1900mm | |

| Color of the machine | Blue and green |

Transportation:

All goods will be shipped to your country, though the number of containers will be determined by the number of products you purchase from us.

Installation of the machine

The individual components of the machine are installed according to the layout of your factory and are then prepared for the commissioning.

The installation includes:

Installation by our own service technicians.

The following services are included:

Installation of the machine components.

Adjustment of the machine components.

Connection of all motors to the control cabinet.

Installation of the required safety devices.

Delivery does NOT include:

Media supply (such as electronic components) to the machine (control cabinet)

Raw material, process material

Raw material for testing

Transport and lifting devices

Auxiliary staff.

The factory employees should be present during the installation in order to become familiar with the new machines.

Commissioning of the machine

The components of the machine are commissioned one after the other. At the end of the commissioning the machine is ready for production and is handed over.

Commissioning includes:

Commissioning by our own service technicians

Machine training

We carry out the following services:

Run up of the machine components

Testing of all machine component functions

Begin the fully automatic molding process

Execution of machine acceptance

Our After-Sales Service Commitments

We have a three part service policy for any equipment sold by us: we will provide installation guidelines, free of charge, commissioning and maintenance of equipment, and buyer/operator training. We will also provide the technical requirements for installation and operation, including technical layout diagrams and other related information. Finally, we also provide lifetime maintenance and spare parts.

The detailed measures are as follows:

1. Guidelines for installation and commissioning of equipment:

Based on the actual situation, we will assist and guide the customer and their technical personnel in the overall installation location, the installation of equipment, and provide the customer with answers to their questions and related issues.

2. Provide training for operation and maintenance personnel:

Based on customer requests, we will provide operation and maintenance personnel with proper training, free of charge.

a) The customer can send their operation and maintenance personnel to our factory for education and training

b) When we are carrying out installation and test running of the equipment for the customer, their employees may be present to assist as needed.

3. If failure occurs in any of the machines during the one year warranty period (warranty covers electrical parts, the rolls, the shafts and punching and cutting molds), then we will fix the problem upon customer request.

4. We will inform customers of any upgrades and significant product improvements. We will also provide equipment modifications based on their costs. Customers will be the recipient of high-quality after-sales services, and we will do everything possible to keep the customer’s production on schedule and at full capacity.

We provide quick and satisfactory customer service, and promise to respond within 24 hours after receiving your complaints by phone or email.

Our Machine and Factory