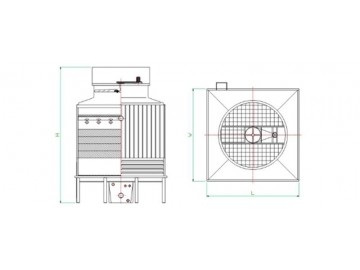

Counterflow Cooler, SKLN

Production Rate: 3~35 (T/H)

Features of Counterflow Cooler

1. This pellet cooler works with an airflow that moves opposite to the pellet flow. During the time the air flow and product flow pass each other, they exchange heat and moisture. Counter flow cooling allows hot pellets to cool down gradually rather than abruptly which avoids thermal shock so fracture or crack becomes less of an issue.

2. The top of our counterflow cooler is made of stainless steel. A rhomboid material distributor ensures materials are spread out evenly.

3. An airlock feeder is used to seal pressurized system against loss of air all while ensuring a continuous flow of materials into the counterflow cooling system.

4. A material level indicator controls the cooling time.

5. Controlled by a slide valve, the discharge mechanism ensures materials are discharged from the system stably, leaving minimum residue.

6. Large counterflow coolers come equipped with a rotary distributor to ensure a uniform thickness of material bed, allowing the cooling air to reach every corner of the cooling chamber.

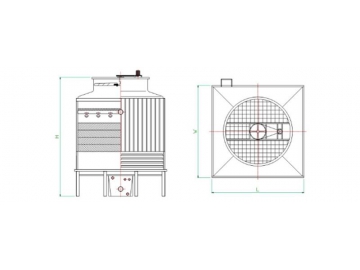

| Model No. | | | | | | |

| Cooling Volume (m³) | 3 | 5 | 7 | 8 | 10 | 12 |

| Capacity (T/H) | 5 | 10 | 15 | 20 | 25 | 30 |

| Cooling Time (MIN) | 10-15 | 10-15 | 10-15 | 10-15 | 10-15 | 10-15 |

| Material Temperature after Cooling ( ℃ ) | 3-5 | 3-5 | 3-5 | 3-5 | 3-5 | 3-5 |

| Air Intake(m³/min.t) | 34 | 34 | 34 | 34 | 34 | 34 |

| Power (KW) | 0.75 | 1.5 | 1.5 | 1.5 | 2.2 | 3 |

| Airlock Feeder Power (KW) | 0.55 | 0.75 | 1.1 | 1.1 | 1.1 | 1.1 |