Low Voltage Reactor/Inductor/Choke (for Inverter)

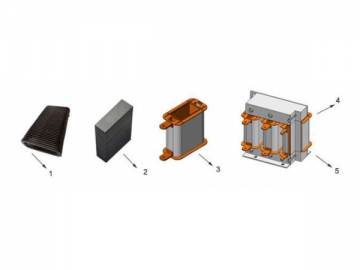

Our low voltage reactors for inverters adopt Siemens technology with a compact structure, lightweight design and low noise output. We produce various low voltage reactors all of them are iron core dry type reactors.

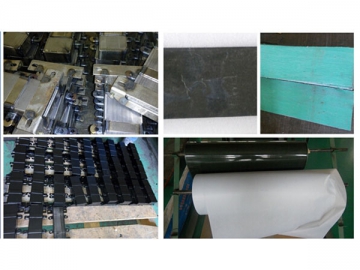

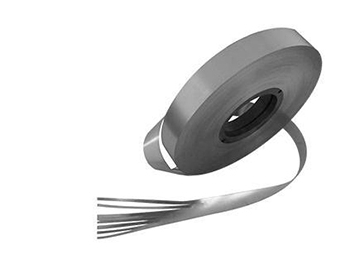

1. The iron core of the reactor uses high quality, low loss cold rolled silicon steel sheet which comes from Wuhan Steel Corp., one of our preferred quality suppliers.

2. The coil of the inductor is made with H class enameled rectangular copper wire for good heat dissipation and performance.

3. The nonmagnetic fasteners in the reactor core reduce eddy current and prevent unwanted heat buildup.

Ordering Requirements:

1. Inverter or Motor Model

2. Source Power

3. Motor Power

4. Output Current

5. Inductance

6. Temperature Class Requirements

Operating Conditions:

1. Operating Temp: -5℃- 40℃ (or according to the customer demand)

2. Storing Temp: -25℃- 40℃

3. Altitude: ≤1000m,If more than 1000m, we will design the non-standard products according to the customer's requests.

4. Maximum wind speed: 35m/s.

5. Relative humidity: <90%。

6. Insulation class: F

Extend the Life of Motor

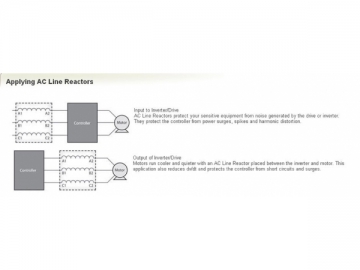

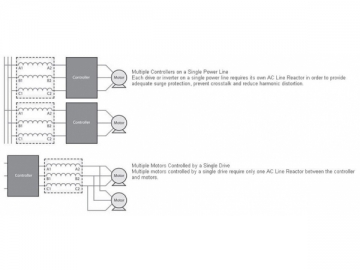

Line reactors, when selected for the output of your drive, will enhance the waveform and virtually eliminate failures due to output circuit faults. Motor operating temperatures are reduced by 10 to 20 degrees and motor noise is reduced due to the removal of some of the high frequency harmonic currents.

Minimize Harmonic Distortion

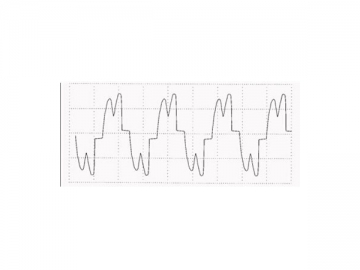

Non-linear current waveforms contain harmonic distortion. By using a line reactor you can limit the inrush current to the rectifier in your drive. The peak current is reduced, the waveform is rounded and harmonic distortion is minimized. Current distortion typically is reduced to 30%.

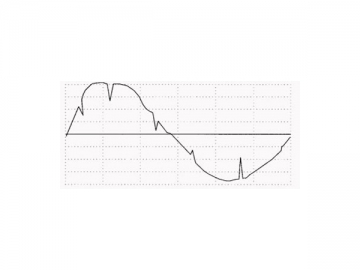

The total harmonic distortion of variable speed drives produces complex wave shapes such as the phase current shown above. The challenge for today's designers is to effectively minimize these line problems.

A voltage waveform illustrating line notching. Line reactors are used to provide the inductive reactance needed to reduce such notches.

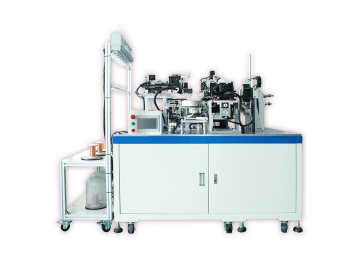

- Wire Winding and Skeleton

- Upper-lower jaw and air gap adjusting material

- Drying and Immersing