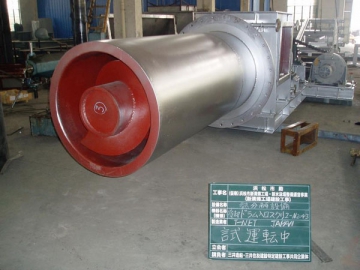

Vertical Screw Conveyor

Inner Workings and Features

1. The vertical screw conveyor is a floor-standing conveying machine boasting a forced-feed screw. Though placed vertically, the auger conveyor has a horizontal part where material enters the system via an inlet port. As the helix screw blade rotates, material is sent to a certain height where it is discharged from the machine.

2. Vertical conveying has to exert a rotary torque greater than the gravity force on the material being conveyed.

3. A constant inlet pressure needs to be maintained to aid in feeding and conveying. For conveying applications with small height difference, the vertical conveyor needs a horizontal inlet section. In that case, the horizontal screw needs to be integrated into the vertical part to form a complete integral unit. Horizontal screw diameter is equal to that of vertical screw, with its rotary speed slightly lower than the latter.

Benefits

Simple structured and compact, the vertical screw conveyor easily fits into narrow spaces. It conveys material in a full enclosed environment without dusting. Manufacturing costs for vertical conveying equipment are relatively low.

Drawbacks

Small material volume

Small conveying height (no more than 8m)

Applications

1. Suitable for conveying various powdery and granular materials, including black carbon, flour, cement, sand, grain, and recycled rubber powder.

2. Not recommended for perishable, sticky, clumpy, and corrosive products.

3. Ambient temperature: -20-50℃, material temperature: under 200℃