EPS Sandwich Panel Machine

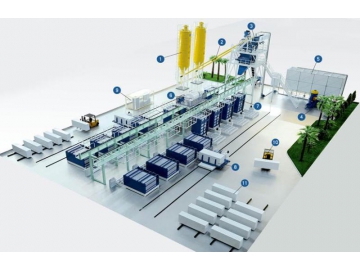

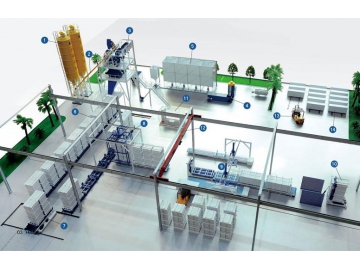

The EPS sandwich panel machine consists of a roll forming equipment and a sandwich panel laminating system. It produces corrugated sandwich panels directly and they can work independently when is needed. The roll forming machine of the production line consists of feeding, roll forming and cutting systems, while the laminating system includes decoiler, feeding, squeezing, heating, laminating, edge rolling edge turn-over, groove-making, edge pruning, pneumatic device, automatic cutting and PLC. Annual production capacity of this EPS sandwich panel machine is about 500,000 m2.

The EPS sandwich panel machine has stylish appearance, low noise and high efficiency. Besides corrugated sandwich panels, it can produce simple corrugated sheets. Through an advanced PLC, it sets the panel length and cuts it automatically. It has been designed based on advanced production techniques combining the advantages of mechanical and electrical equipment.

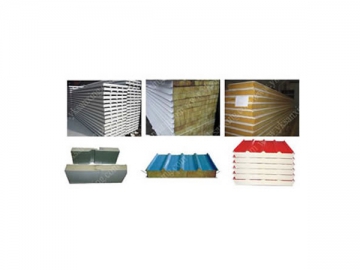

The results of the EPS sandwich panel machine production are commonly used as roof and walls for factories, warehouses, garages, gymnasiums, exhibition centers, cinemas, theatres, civil constructions, stadiums, cold storages and many other places with multiple applications.

Main Technical Specifications of the EPS Sandwich Panel Machine

Controlling system: PLC

Total power including heating: 40 kW

Working speed: 1000 mm/min to 3000 mm/min

Density of EPS: >18 kg/mm

Suitable material for production: 1000 mm ~ 1200 mm × (0.5~0.6 mm)

Size: 38000 mm × 3600 mm × 3300 mm

Total weight: 24000 kg