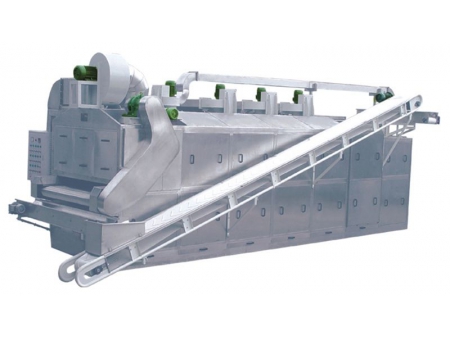

Multi-Layer Belt Dryer

Request a Quote

HGD-1.7M Series

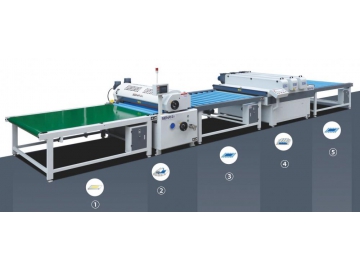

HGD-1.7M multi-layer belt dryer is a food drying equipment specially developed by Walley to improve productivity and reduce labor costs. It consists of a drying cabinet, heating device, fans, conveyor belt, and automatic control device.

With relatively small factory footprint, high drying efficiency, and easy operation and optional PLC control, the belt dryer is an ideal choice for drying various products in granular, strip, and flake forms, such as onions, garlic, shrimp skins, clams, honeysuckle, rice, and various vegetables, fruits, and flowers.

Samples

Fresh Onion

Fresh Onion Dried Onion

Dried Onion Fresh Edible Fungus

Fresh Edible Fungus Dried Edible Fungus

Dried Edible Fungus

Specifications

| Model | Drying area (m²) | Drying capacity (kg H2O/h) | Steam consumption (kg/h) | Drying temperature (℃) | Drying time (min) | Power (kW) | Dimensions (m) |

| 62 | < 620 | 1200 | < 110 | 15-75 | 25.35 | 9.3×3.6×3.6 | |

| 78 | < 780 | 1600 | < 110 | 15-75 | 37.25 | 11.3×3.6×3.6 | |

| 94 | < 940 | 2000 | < 110 | 15-75 | 46.95 | 13.3×3.6×3.6 | |

| 110 | < 1100 | 2400 | < 110 | 15-75 | 56.65 | 15.3×3.6×3.6 | |

| 127 | < 1270 | 2800 | < 110 | 15-75 | 68.55 | 17.3×3.6×3.6 | |

| 144 | < 1440 | 3200 | < 110 | 15-75 | 78.25 | 19.3×3.6×4.0 | |

| 160 | < 1600 | 3600 | < 110 | 15-75 | 90.15 | 21.3×3.6×4.0 |

Features

Multi-layer drying allows for efficient utilization of hot air, reducing energy waste.

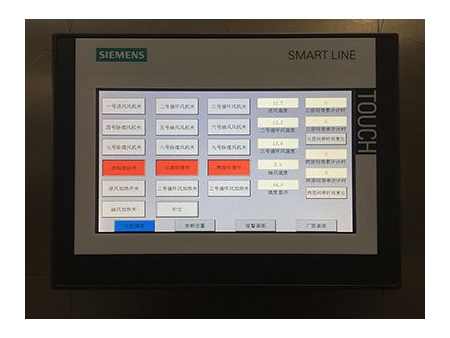

Multi-layer drying allows for efficient utilization of hot air, reducing energy waste. PLC control allows for easy operation and high degree of automation.

PLC control allows for easy operation and high degree of automation. Heating pipes are installed between each layer to stabilize the temperature and improve the quality of the drying products.

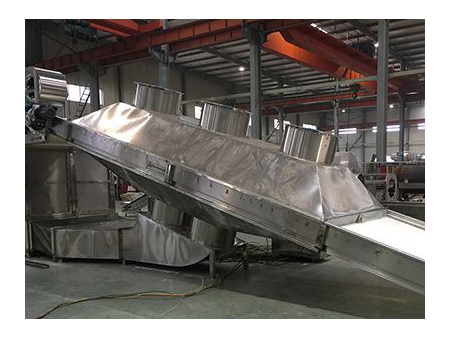

Heating pipes are installed between each layer to stabilize the temperature and improve the quality of the drying products. The feeding material elevator recycles the excess heat from the drying section, saving energy and improving drying efficiency.

The feeding material elevator recycles the excess heat from the drying section, saving energy and improving drying efficiency. There are observation doors installed on both sides, allowing for observation of the drying process inside the cabinet.

There are observation doors installed on both sides, allowing for observation of the drying process inside the cabinet. Steam is controlled using pneumatic valves to avoid the aging issue commonly seen in electromagnetic valve coils. This prolongs the lifespan and reduces maintenance costs.

Steam is controlled using pneumatic valves to avoid the aging issue commonly seen in electromagnetic valve coils. This prolongs the lifespan and reduces maintenance costs. The hot air drying equipment uses high-quality steam trap systems for automatic drainage control, preventing water accumulation in the heat exchanger and improving its efficiency.

The hot air drying equipment uses high-quality steam trap systems for automatic drainage control, preventing water accumulation in the heat exchanger and improving its efficiency. The feed inlet is equipped with a material distribution shaft to ensure uniform material distribution, thereby achieving better drying results. The drying device is adjustable in height, making it suitable for processing products of different thicknesses or sizes.

The feed inlet is equipped with a material distribution shaft to ensure uniform material distribution, thereby achieving better drying results. The drying device is adjustable in height, making it suitable for processing products of different thicknesses or sizes.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos