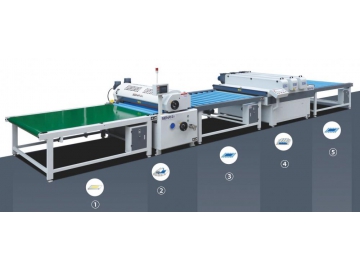

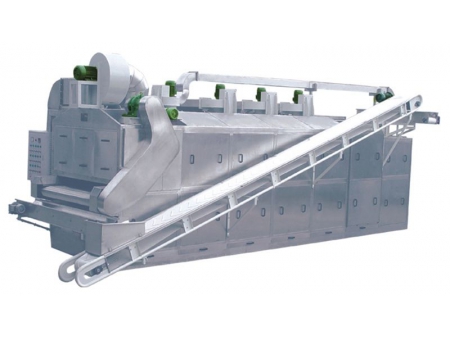

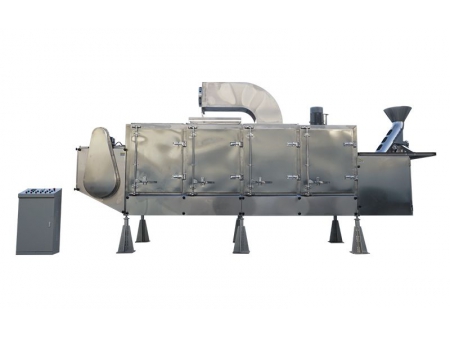

Single-Layer Belt Dryer

HGD-2S Series

HGD-2S series single-layer dryer is commonly used in combinations of two or more units, and it can also be combined with the HGD-1.7M multi-layer belt dryer. This series of hot air dryers is suitable for drying food products in granular, strip, and flake forms.

Fresh Cabbage

Fresh Cabbage Dried Cabbage

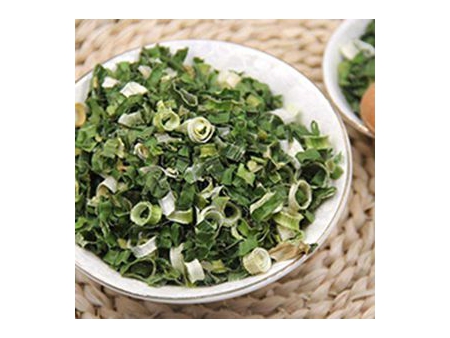

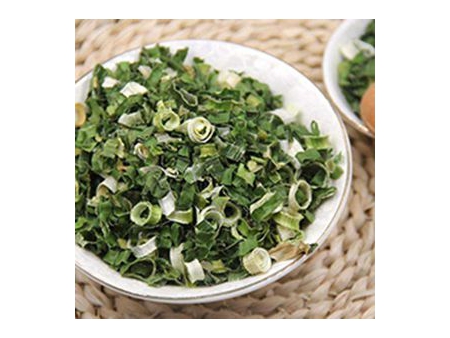

Dried Cabbage Fresh Scallion

Fresh Scallion Dried Scallion

Dried Scallion

| Model | Drying area (m²) | Drying capacity (kg H2O/h) | Steam consumption (kg/h) | Drying temperature (℃) | Drying time (min) | Power (kW) | Dimensions (m) |

| HGD-2S-32 | 32 | 200-1000 | 1000-2000 | < 120 | 20-100 | 63.75 | 18.0×3.15×4.0 |

The feed inlet is equipped with a material distribution shaft to ensure uniform material distribution, thereby achieving better drying results. The drying device is adjustable in height, making it suitable for processing products of different thicknesses or sizes.

The discharge outlet is equipped with a dispersing device to prevent material clumping during the heating process. The exit is also fitted with a scraping device to prevent material from sticking to the conveyor belt, facilitating the discharge process.

Steam is controlled using pneumatic valves to avoid the aging issue commonly seen in electromagnetic valve coils. This prolongs the equipment's lifespan and reduces maintenance costs.

The hot air dryer uses high-quality steam trap systems for automatic drainage control, preventing water accumulation in the heat exchanger and improving its efficiency.

The material inlets and outlets are equipped with brush cleaning devices to ensure the cleanliness of the conveyor belt, meeting the requirements of food hygiene standards.

Stainless steel conveyor belts are used to ensure safety, hygiene, durability, and low maintenance costs.

High-quality heat exchangers are used, with steel pipes, aluminum fins and a stainless steel shell, ensuring a large heat exchange area and high heat transfer efficiency. According to user requirements, direct heating can be achieved using burners.