Multifunctional Modified Asphalt Plant

Multifunctional Modified Asphalt Plant

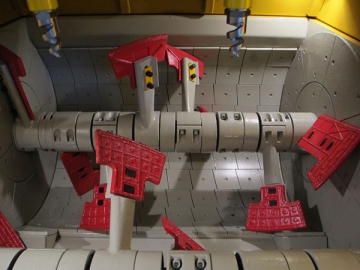

Used to produce polymer modified asphalt and crumb rubber modified asphalt, the multifunctional modified asphalt plant is composed of main body, asphalt heating tank, rotary feeder, hot oil heater and control room. The main body mainly consists of pre-mixing tank, reaction tank (two), colloid mill, electronic weighing system, etc. All tanks are equipped with high-efficiency hot oil heating coils.

Main Technical Specification

Model | LGS-15 | LGS-20 | LGS-30 |

Max. Productivity (t/h) | 15 | 20 | 30 |

Precision of weighing system (%) | ±5 | ±5 | ±5 |

Heat capacity of hot oil heater (kcal/h) | 80×104 | 80×104 | 120×104 |

Milling fineness(μm ) | < 5 | < 5 | < 5 |

Total power (kW) | 245 | 265 | 305 |

Total weight (t) | 42 | 42 | 51 |

Overall dimensions of the main body (L×W×H) (mm) | 12350×2800×3100 | 12350×2800×3100 | 13000×2800×3120 |

Main Performance

The multifunctional modified asphalt plant is applicable to multiple modifiers, such as SBS,

|

|

|