Aluminum Can Cap

Aluminum Can Cap

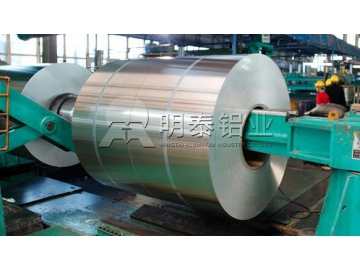

Alloy & Specification

| Alloya | Coated panel,strip status | Status | Aluminum thickness a t /mm | Aluminum Specificationa /mm | Aluminum coil specificationa /mm | ||

| Width | length | width | Steeve Φ | ||||

| 5052 、 5182 | H46 、 H48 、 H49 | H18 、 H19 、 H36 、 H38 、 H39 | 0.22≤t≤0.50 | 500 ~ 1600 | 500 ~ 4000 | 20 ~ 1600 | 300 、 350 、 405 、 505 |

| a .Other alloy, specification of material can be negotiated | |||||||

Aluminum Thickness

| Aluminum thickness | Thickness tolerance ( ± ) |

| > 0.22 ~ 0.30 | 0.005 |

| > 0.30 ~ 0.50 | 0.008 |

Width and Length

| Alloy | Aluminum panel&coil length tolerance/mm | Aluminum Panel&coil width tolerance/mm /mm | ||||

| Pop top | Pop can cover | |||||

| Length ≤2000 | Length >2000 | width ≤100 | width >100 | width≤1000 | width >1000 | |

| 5052 5182 | 1 0 | 2 0 | ± 0.2 | 1.5 0 | 1.0 0 | 1.5 0 |

Dynamic features

| Alloy | Status | thickness ( t ) /mm | Room temperature tensile test results | ||

| Tensile strength R m /MPa | non-proportional extension strengthRp0.2/MPa | elongationA50mm /% | |||

| ≥ | |||||

| 5052 | H36 | > 0.22 ~ 0.30 | 255 ~ 305 | 200 | 2 |

| > 0.30 ~ 0.50 | 255 ~ 305 | 200 | 3 | ||

| H18 、 H38 | > 0.22 ~ 0.30 | 270 | 210 | 2 | |

| > 0.30 ~ 0.50 | 270 | 210 | 3 | ||

| H19 、 H39 | > 0.22 ~ 0.30 | 290 | 220 | 2 | |

| > 0.30 ~ 0.50 | 290 | 220 | 3 | ||

| 5182 | H36 | > 0.22 ~ 0.30 | 265 ~ 340 | 270 | 3 |

| > 0.30 ~ 0.50 | 265 ~ 340 | 270 | 4 | ||

| H18 、 H38 | > 0.22 ~ 0.30 | 330 | 285 | 3 | |

| > 0.30 ~ 0.50 | 330 | 285 | 4 | ||

| H19 、 H39 | > 0.22 ~ 0.30 | 340 | 295 | 3 | |

| > 0.30 ~ 0.50 | 340 | 295 | 4 | ||

Coating function

Suppliershould ensure DOS oil of pop can cover is up to 5~10mg/m2/side,and coating surface should be with even wax which is up to 40~100mg/m3/side

Food and packing industry pop can cover coating aluminum panels’ features:

| Function | Coating weightg/m2 | Deviation of coating | T | MEK | High temperature sterilization | S R esist- ance | Acid resista- nce | Adhe - sion | |

| Pop can Cover | Outer coating | 3 ~ 6 | ≤10 | ≤2 | > 50 | See Note.1 | - | - | 1 Grade |

| Inner coating | 10 ~ 13 | ≤10 | ≤2 | - | See Note.1 | See Note.2 | See Note3 | 1 Grade | |

| Pop can tab | 2 sides coating | 3 ~ 6 | ≤10 | ≤2 | > 50 | See Note.1 | - | - | 1 Grade |

| Note : 1 After121 ℃, 30min distill, internal and external coating without white, loss of light, peeling, and shedding. 2 After121 ℃, 30min S corrosion, internal and external coating without white, loss of light, peeling, and shedding. 3 After121 ℃, 30min acid erosion, internal and external coating without white, loss of light, peeling, and shedding. | |||||||||

Appearance

Thesurface of the pop cans cover coating does not allow defects such as airbubbles, scratches, missing coating, over-burning, oil spots, stains, streaks,color, piebald, roller printing, embossing, periodic prints, chemical liquidetc which impact users.

Each coil allowed a joint which does not allow loose layer or dislocation, thejoint can only be overlapped, which need to make the mark in the end, and eachbatch coil of joint is not more than 10% of the total number of coils.

Services

Supportingservices: Offering semi-finished products & OEM services

美工放图:罐盖料拉环