Asphalt Plant

The JRM series asphalt plant produces asphalt mixture and modified asphalt mixture, which can be used in the construction of highways, grade highways, city roads, airports, ports, etc.

Our asphalt mixing plant integrates European and American leading technology and our accumulated expertise. The asphalt plant is modular, standardized, generalized, and intelligent, focusing on being energy-saving and cost-effective. A variety of configurations and solutions can be provided with this asphalt batching plant in accordance with customer demand.

Structure of Asphalt Plant

The asphalt plant consists of electronic control system, cold aggregate supply system, drum dryer, dust collecting system, mixing tower, weighing system, asphalt storage and heating system, filler supply system and finished asphalt storage bin.

1. Electronic Control System

The control over the entire asphalt plant is done by PC / PLC, which allows manual, semi-automatic, and fully automatic control. The functions include process parameter settings and modification, formula input, drop automatic correction, bitumen-aggregate ratio dynamic tracking, automatic troubleshooting, automatic alarm, report printing and data storage. The PLC is of SIEMENS standard industrial component and the PC is of standard industrial-grade computer.

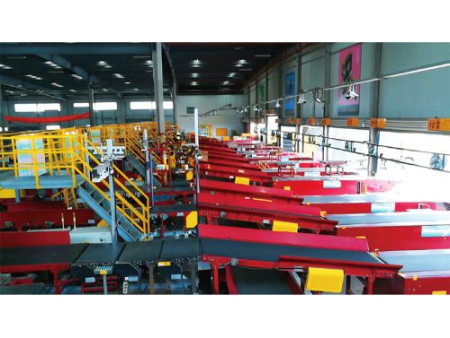

2. Cold Feed System

The cold feed system of the asphalt plant adopts integrated cold feed hopper. The shield and the grid plate for feeding large materials are mounted above the hopper. The outlet has material interrupt alarm device. The feeder feeds according to primary frequency control. The sand silo for the asphalt equipment is equipped with vibrators, and the inclined belt conveyor is equipped with a large material reject bin. Hopper and feeder design effectively eliminate bridging and prevent belt damage.

3. Drum Dryer

Wall of the drum dryer uses rock wool insulation cased in galvanized steel. The discharge end is sealed with heat-resistant rubber seals, allowing sufficient heat exchange and minimal heat loss, saving energy and enhancing the ability to adapt to the environment. The burner of the asphalt plant adopts CNC inverter technology to be capable of burning heavy oil and residual oil.

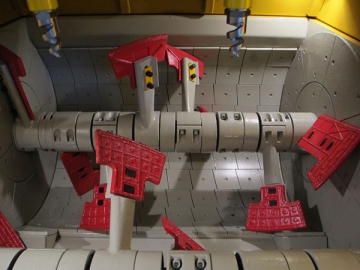

4. Mixing Tower

The asphalt mixer design of the asphalt plant features European technology. The chain bucket, feed chute, and discharge port of the hot aggregate elevator are welded with wear-resistant steel plate. The mixing tank is of horizontal shaft drive, and there are four plans available for customers to choose from: 4-group screening type, 5-group screening type, 6-group screening type, and 7-group screening type, which can meet asphalt mixture production at all levels. The hot storage bin is designed to have reasonable distribution ratio.

5. Weighing System

For this asphalt plant, material level monitoring can be carried out in two ways: point or continuous. The PC dynamic automatic compensation effectively controls the aggregate measurement accuracy. All aggregate weighing scales, powder weighing scales and asphalt weighing scales adopt world famous sensors. The asphalt measurement is of dynamic weighing mode, with gap correction function to ensure accurate measurement, limiting the deviation of asphalt content within the range of 0.2%.

6. Dust Collecting System

The dust removal system for the asphalt mixing equipment includes cyclone dust removal and bag filter dust removal. The bag filter works in pulse-line injection mode, and through pulse meter, it automatically controls cleaning. The bag filter is manufactured by DuPont NOMEX with high temperature and ultra-high temperature protection, allowing the filter temperature to remain within the desired controllable range. The cleaning device ensures the best working condition of the bag filter, as well as the continuous and efficient production capacity of the asphalt plant.

7. Asphalt Storage and Heating System

The asphalt plant is equipped with oil-, coal-burning type heat transfer oil furnace, imported burner and heat transfer oil circulation pump.

8. Filler Supply System

The discharge port of filler supply system takes air blowing and vibration as combined arch breaking method. Air blowing feeding and elevator feeding are two available plans for new material feeding, and recycled material feeding is done by the Roots blower.

9. Finished Asphalt Storage Bin

The finished asphalt storage bin of the asphalt plant is available in sub-mounted and side-mounted types. The structural design avoids isolated silos, and the material discharge can be completed either in-plant or on-site. The outer wall takes a variety of measures for heat insulation.

In summary, JRM series asphalt mixing plant has the following advantages:

Modular—modular equipment package is designed for easy assembly, disassembly, and transitions, which can effectively save floor space.

Intelligent— the asphalt plant adopts fully automatic computer process control. PC / PLC is the core of the control system, enabling manual, semi-automatic and fully automatic control.

Energy Saving—digital inverter burner technology allows the use of heavy oil, residual oil.

Green—inertia pulse bag filter ensures the compliance with strict environmental standards.

Stability—main components are of internationally renowned brands, ensuring stable and reliable equipment operation.

Major Components

-

Environmental type overflow silo and over-spec silo

The excess material after screening out flowing through a overflow silo can be available for secondary use.

After the screening, over-spec materials outflows from overrun silo. -

Cold feed hopper

Each cold hopper stores aggregates of different specifications, and sends them to the drying drum by the transfer device. -

Bag filter

DuPont material bag, using a pulse-line row injection mode, make sure to meet environmental requirements. -

Drying drum

The dryer drum wall uses rock wool insulation cased in galvanized steel to ensure minimal heat loss. The drum is used for aggregate drying heating, so as to achieve the expected temperature. -

Shaker

German technology sieve shaker can screen aggregates according to different particle sizes to meet requirements of all grades of asphalt production. -

Burner

The digital inverter burner can accept diesel, heavy oil, and residual oil, which can effectively save fuel costs. -

Finished material silo

The silo is used for storing finished material, according to the site area, it can be next-mounted or side-mounted. -

Control room

The control room is equipped with air conditioning. PC / PLC enables manual, semi-automatic, and fully automatic control. -

Mixing tower

The tower mixes aggregates, powders, and bitumen into construction required asphalt mixtures.

JRM specializes in a great variety of road equipment. We are a professional asphalt plant manufacturer in China. To know more, please contact us.