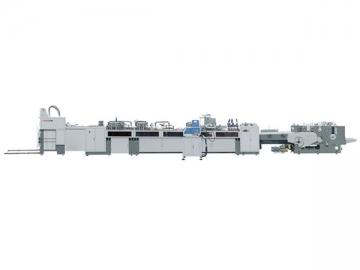

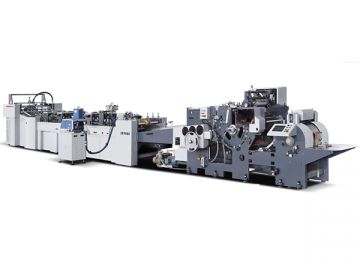

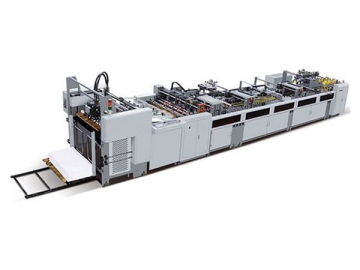

ZB1300B-1 Paper Bag Forming Machine

The ZB1300B-1 paper bag forming machine designed in the year of 2011 is suitable for the paper with wide range of thickness. As compared with ZB1300B type, this semi-automatic paper bag making machine features higher intelligence and can complete bottom folding apart from tube forming. In addition, it can also be equipped with one of our wide assortment of bottom gluing machines such as ZB50B, ZB60B, ZB50B-2, and ZB80B for bottom pasting.

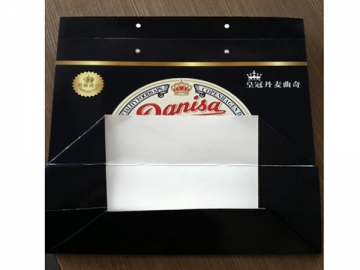

This paper bag forming equipment is applied to mass production of high-end paper bags by various types of glazed paper and film adhesive paper, as well as specialty paper. With regard to the manufacture of medium and high-end handbags or handbags for packing luxury items, this type of paper bag forming machine is an ideal choice.

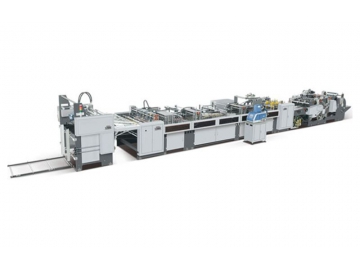

Characteristics

1. The color shopping bag equipment can enjoy non-stop paper feeding in that it is equipped with an enhanced pre-stack paper feeder. Thereby, paper load and adjustment time can be greatly saved.

2. Owing to the front and side guides, every sheet of paper can obtain accurate positioning, thus ensuring uniformity of the bags.

3. The gluing system with out delicate design can achieve synchronous gluing of water soluble cold glue and hot melt glue, and separate gluing of hot melt glue as well.

4. The gluing system boasts two types of adhesive gluing device. To illustrate, tape roll is designed for gluing cold glue while spray gun for hot melt glue.

5. The semi-automatic paper bag forming machine is designed with an advanced screw rod adjusting device. This unit contributes to the considerable reduction of machine adjusting time when the manufacture of different paper bags is required.

6. As a reusable paper bag machine, our product comes with an automatic bottom folding device which can fold the bag bottom automatically so as to greatly save labor costs.

Technical Parameters

| Max. sheet size (L×W) | 1200×650mm |

| Min. sheet size (L×W) | 700×360mm |

| Sheet weight | 100g-300g/m2 |

| Bag width | 250-450mm |

| Bottom width | 80-180mm |

| Bag length | 250-530mm |

| Total power | 14kw |

| Machine dimensions | 14300×2400×1800mm |

| Production speed | 60-90pcs/min |

| Total weight | 12T |

| Glue type | Water soluble cold glue (or hot melt glue) |

Applicable paper

Suitable paper: Kraft paper, art paper, white board paper, white cardboard (including film adhesive paper)

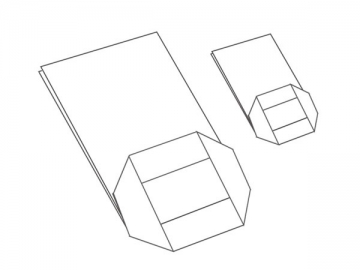

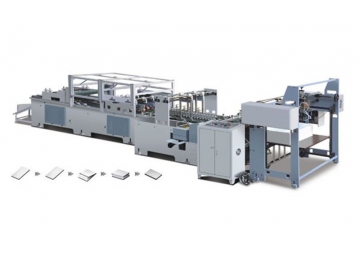

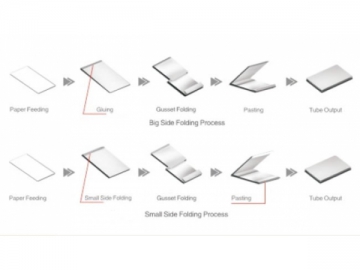

Technological Process

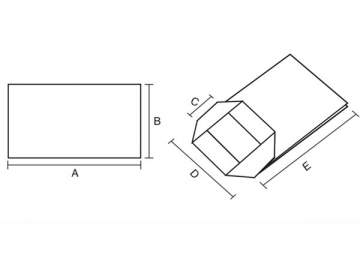

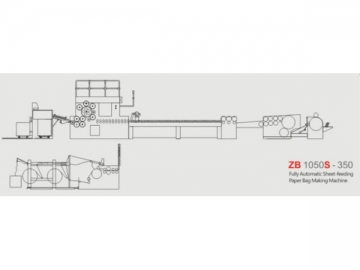

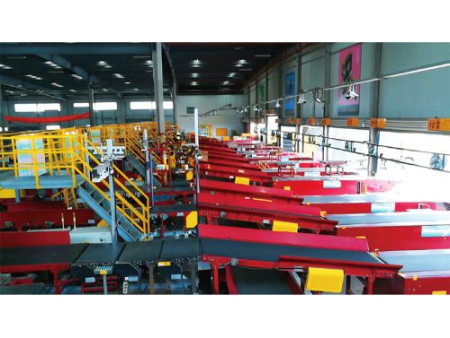

Production Sketch

| A | B | C | D | E | |

| Max. Size (mm) | 1200 | 650 | 180 | 450 | 530 |

| Min. Size (mm) | 700 | 360 | 80 | 250 | 250 |