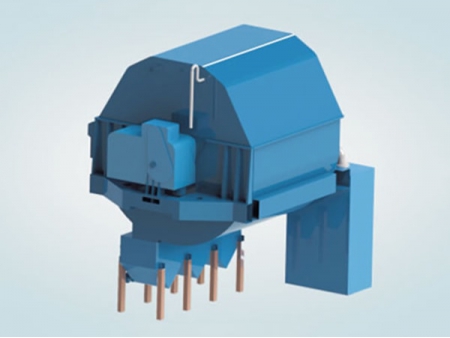

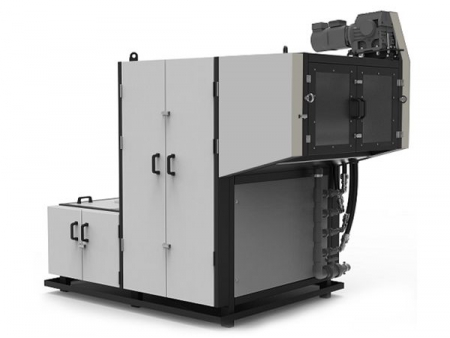

Belt Filter Press / Thickener

Request a Quote

(for Sludge Handling System)

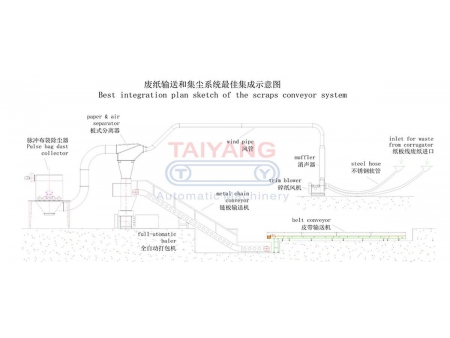

The belt filter press is a kind of thickener for sludge handling system. It is a sludge dehydrator that transforms the processed sludge from low consistency to high consistency. Sludge is gradually dehydrated in different areas by means of gravity dewatering, wedge dewatering, swing dewatering, cut dewatering and other methods. Finally, dry sludge could be obtained. The whole process could be divided into the following zones.

Features

- Feeding: Sludge is put into a container via pipe in the belt filter press. It is uniformly distributed on the gravity dewatering filter belt with the feed concentration of over 1-3% and the feeding temperature of about 20 degrees Celsius. The feed quantity is controlled by a feed valve. Large deviation in concentration and temperature may affect the dehydrating performance.

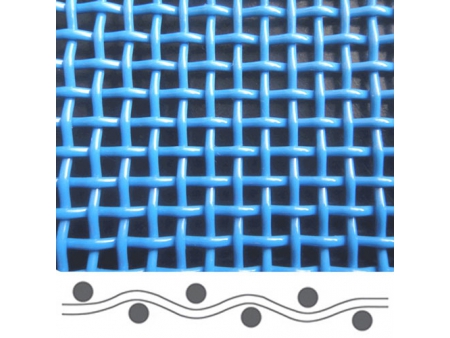

- Gravity dewatering: This gravity thickener is mainly used to remove the free water from sludge so as to decrease flexibility and also increase pressure resistance.

- Wedge dewatering: Similar to gravity dewatering zone, the wedge dewatering zone is designed with a definite edge finder so as to avoid low consistency sludge loss. With the tensile force of wedge screen belt, sludge pressure is continuously increased and the water between flocs and particles will be also unceasingly overflowed. The gravity dewatering zone and wedge dewatering zone account for three fifths of the whole dewatering zone in the belt filter press. This proportion can be increased or decreased in accordance with sludge property.

- Swing dewatering: After passing through above-mentioned two dewatering zones, the sludge has become high consistency filter cake. With the extrusion force generated during screen belt tensioning and swing dewatering process, the filter cake loses much water. The dewatering amount in swing dewatering zone is the highest, and the sludge concentration could reach over 15%.

- Cut dewatering: When the screen belt mixed with sludge enters a roller of small diameter, the tensioning of filter belt could produce a large squeezing force. Additionally, the shearing force produced due to different directions of turning roller makes sludge bear high pressure up to 0.5Mpa. Therefore, the sludge with stable moisture could be obtained after passing through the cut dewatering zone of the belt filter press.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos