H Frame Hydraulic Compression Moulding Press

Request a Quote

Applications

Deep draw press is applied in production techniques, like deep drawing, stamping, cutting, bending, flanging of metal sheet.

Particularly applied in the following industries:

- Automobile Industry: Steel ring, vehicle body, chasis, axle housing, fuel tank, door, wheelbarrow tray and more.

- Household Appliance Industry: Components for air conditioner, refrigerator, washing machine, electric cooker etc.

- Kitchen Ware Industry: Stainless steel utensil, LPG cylinder, cooking bench, etc.

- Aluminum Cookware.

High Reliability

- Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,

- The entire equipment totally security (according to EN292:1994, EN60204:1994 and NR12) and defined as Level 4 of safety.

- Intrinsic hydraulic safety valve block with redundant control and dynamic monitoring carried out by a security interface

- Right side protection: vertical door, pneumatic actuating, made of aluminium frame and polycarbonate transparate plates.

Specifications

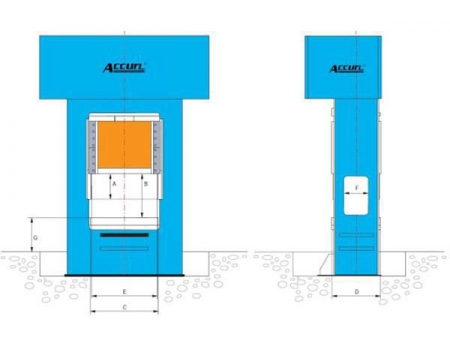

- A = Ram stroke

- B = Maximum installation height

- C = Table width

- D = Table depth

- E = Daylight between guides

- F = Lateral throughway

- G = Table height above floor

| Model | HSP-200 | HSP-250 | HSP-315 | HSP-400 | HSP-500 | HSP-630 | HSP-800 | ||

| Capacity | kN | 2000 | 2500 | 3150 | 5000 | 4000 | 3150×2 | 8000 | |

| Return Force | kN | 240 | 400 | 600 | 900 | 500 | 450×2 | 1000 | |

| Slide Stroke | mm | 710 | 710 | 800 | 900 | 800 | 900 | 1000 | |

| Shut Height | mm | 1120 | 1120 | 1200 | 1400 | 1200 | 1500 | 1800 | |

| Hyd . Pad Capacity | kN | 630 | 1000 | 1250 | 2000 | 1250 | 1250×2 | 1600×2 | |

| Hyd . Pad Return Forc | kN | 250 | 320 | 360 | 780 | 360 | 360×2 | 600×2 | |

| Hyd . Pad Stroke | mm | 250 | 250 | 300 | 350 | 300 | 350 | 400 | |

| Slide Speed | Idle Stroke | mm/s | 200 | 220 | 150 | 140 | 180 | 150 | 150 |

| Pressing | mm/s | 8~19 | 9~20 | 10~22 | 8~19 | 9~20 | 8~19 | 8~18 | |

| Return | mm/s | 140 | 120 | 120 | 90 | 160 | 130 | 140 | |

| Hyd . Pad Speed | Eject | mm/s | 60 | 50 | 55 | 45 | 60 | 45 | 45 |

| Return | mm/s | 150 | 155 | 140 | 165 | 220 | 165 | 125 | |

| Bolster | LR | mm | 1200 | 1200 | 2200 | 1500 | 1750 | 2500 | 2200 |

| FB | mm | 1000 | 1000 | 1600 | 1200 | 1250 | 1800 | 1600 | |

| Hydraulic Pad | LR | mm | 950 | 950 | 1720 | 1120 | 1270 | 2020 | 1570 |

| FB | mm | 800 | 800 | 1120 | 820 | 820 | 1270 | 1120 | |

| Outline Size | LR | mm | 3280 | 3380 | 4700 | 3900 | 4250 | 5100 | 4900 |

| FB | mm | 2000 | 2100 | 3100 | 2500 | 2750 | 3400 | 3300 | |

| Above Floor | mm | 3900 | 4300 | 5800 | 5200 | 5350 | 6200 | 6700 | |

| Main Motor Power | kW | 22 | 30 | 37 | 2×30 | 2×22 | 2×30 | 2×37 | |

| Weight | kg | 13000 | 16200 | 25000 | 57000 | 31000 | 80000 | 90000 | |

| Model | HSP-1000 | HSP-1000A | HSP-1250 | HSP-1500 | HSP-1500A | HSP-2000 | ||

| Capacity | kN | 10000 | 4000 3000×2 | 6300 3150×2 | 6000 4500×2 | 6000 4500×2 | 8000 6300×2 | |

| Return Force | kN | 1350 | 560×2 | 850 600×2 | 625×2 | 625×2 | 1000 850×2 | |

| Slide Stroke | mm | 1000 | 1500 | 1300 | 1500 | 1600 | 1600 | |

| Shut Height | mm | 1800 | 2200 | 1800 | 2000 | 2200 | 2200 | |

| Hyd . Pad Capacity | kN | 2000×2 | 700×4 1250 | 2000×2 | 1000×4 1600 | 1000×4 1600 | 1600×4 | |

| Hyd . Pad Return Force | kN | 580×2 | 400 | 580×2 | 610 | 610 | 600×4 | |

| Hyd . Pad Stroke | mm | 400 | 400 | 400 | 450 | 450 | 500 | |

| Slide Speed | Idle Stroke | mm/s | 160 | 280 | 150 | 150 | 150 | 130 |

| Pressing | mm/s | 8~19 | 15~30 | 7~15 | 8~19 | 8~19 | 8~18 | |

| Return | mm/s | 140 | 250 | 90 | 150 | 150 | 150 | |

| Hyd . Pad Speed | Eject | mm/s | 45 | 150 | 45 | 100 | 100 | 55 |

| Return | mm/s | 155 | 150 | 155 | 150 | 150 | 145 | |

| Bolster | LR | mm | 2500 | 4500 | 3500 | 4000 | 4500 | 4600 |

| FB | mm | 1800 | 2600 | 2000 | 2600 | 2600 | 2600 | |

| Hydraulic Pad | LR | mm | 2020 | 3520 | 2920 | 3220 | 3520 | 3820 |

| FB | mm | 1270 | 1870 | 1420 | 2020 | 1870 | 2020 | |

| Outline Size | LR | mm | 4000 | 6800 | 5500 | 5600 | 6100 | 6200 |

| FB | mm | 3500 | 4000 | 3800 | 4000 | 4000 | 4200 | |

| Above Floor | mm | 6800 | 9000 | 7300 | 8000 | 8300 | 8600 | |

| Main Motor Power | kW | 3×37 | 3×55 | 3×37 | 3×55 | 3×55 | 3×75 | |

| Weight | kg | 100000 | 210000 | 180000 | 240000 | 265000 | 37000 | |

Characteristics

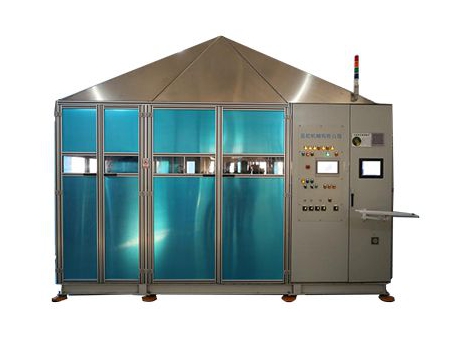

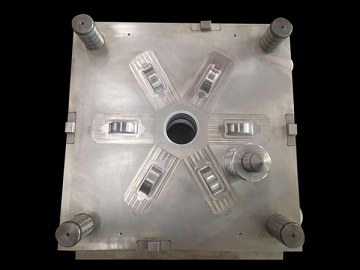

- Totally European streamlined design, Monoblock welded steel frame rigid & Heat Treated. the Press body is reasonably designed through finite element structural analysis and optimization. It is mainly applied to compression moulding of SMC/FRP sheets.

- The press is equipped with advanced and systemized Taiwan hydraulic system featuring oil leakage resistance, anti-vibration, low energy consumption, low noise level and easy maintenance.

- Eight sides of brass guide rails of full stroke length not only ensure high accuracy but also allow easy adjustment of slide leveling.

- Constant pressure and stroke can be set for same production. It is also functioned by adjustable pressure holding time delay.

- The press fully meets CE safety requirements. Two side locking cylinders lock the slide when it reaches top position. And two sets of light curtain sensors are fitted in the front and rear that will stop the machine when human body carelessly enters the working area

- Mitsubishi PLC and 7 / 10 inch Taiwan Weinview touch screen make the machine easy for operation and specification adjustable.

- Each press is manufactured under strict quality control management with good quality components from France, Japan, Germany, USA and Taiwan to assure the best performance and accuracy.

Optional

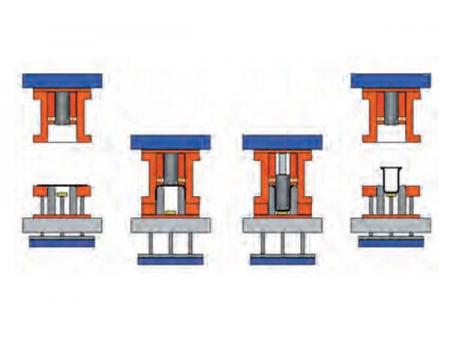

- Moving Bolster

- Stamping Dampers for shock proof while stamping

- Trolley / Moving Bolster for easy die change

- Cushion Device for anti-shock while stamping

- Water Cooler / Oil Chiller

- Mould Hydraulic clamping

- Air breathing design as per request

- Accumulators for fast speed and low energy consumption

Configuration list

| No. | Item | Standard MAKE | High Standard MAKE |

| 1 | PLC | Mitsubishi | Siemens |

| 2 | Motor | WanNan/China top brand | Siemens / Rexroth |

| 3 | Pump | Anson/Taiwan, Yuken/Japan | Siemens / Rexroth |

| 4 | Servo Pump | DAIKIN/Japan | DAIKIN/Japan |

| 5 | Directional Valve | Yuken/Japan | Atos/Italy, Rexroth |

| 6 | Proportional Valve | Yuken/Japan | Atos/Italy, Rexroth |

| 7 | Cartridge Valve | Jeou Gang/Taiwan,SUN/USA | SUN, Atos, Rexroth |

| 8 | Prefill Valve | TAI COLN/Taiwan | Atos/Italy, Rexroth |

| 9 | Electric Units | Schneider/France | Schneider/France |

| 10 | Light Curtain | LNTECH with CE Mark | LNTECH with CE Mark |

| 11 | Touch Screen(HMI)9 | Weinview/Taiwan | Siemens |

| 12 | Pressure Gauge | SKON/Taiwan | S KON/Taiwan |

| 13 | Hydraulic Manifold | MADE IN TAIWAN | MADE IN TAIWAN |

| No worse quality components are adopted in ACCURL Presses. | |||

Related products

Send Message

Other Products