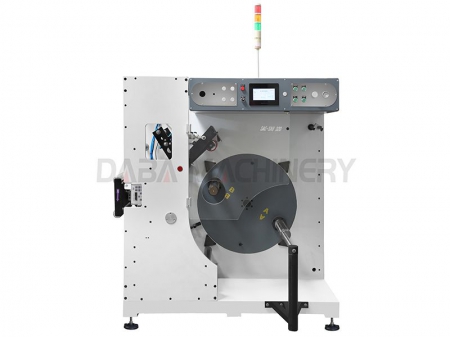

Non-Stop Unwinder Splicer, WBU-C350

Request a Quote

View All: http://conversion-machine.com/4-5-non-stop-unwinder-splicer-for-laminates-foil-stamped-labels.html

Automatic unwinding and butt splicing machine for laminates and foil stamped labels

The non-stop unwinder splicer is a crucial automated equipment for the lamination and foil stamping processes. It connects two paper rolls together, usually joining the end of one roll to the beginning of another.

Maximum unwinding diameter: 450mm (17.7″)

Applicable Materials

All rolls including plastic films, self-adhesive labels, thermal paper, aluminum foils, etc.

Applications

Non-stop cold foil stamping and rewinding.

Features

- Flexible design that can meet almost all demands from customers.

- Simple procedures eliminate the need for specialized training.

- The rewinder is equipped with a stable tension control system using piecewise tension coupling.

- Available for installing two full-width rolls

- Equipped with roll cutting and splicing device that is reliable and easy-to-control, facilitating clean cutting and tight splicing.

- Fully automatic side guide for both opaque and transparent rolls.

- Three adjustable settings for automatic unwinding: manual, roll diameter adjustment, and length adjustment.

- Automatic unwinding with EPC function (web guiding system for edge positioning control). This feature ensures alignment between the running roll and the roll prepared in the splicing unit. Sensors monitor the position of the running roll, and the automatic side guide moves to ensure alignment during splicing.

- Tension coupling technology in the material rack ensures accurate tensioning when entering the roll.

- This non-stop unwinder monitors the diameter of operating rolls and automatically changes rolls to the preset diameter. Alternatively, the tail gripping function initiates splicing when material separates from the core, maximizing material usage and reducing waste.

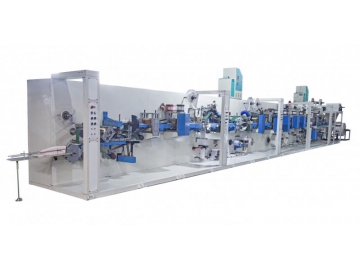

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos