Light Steel Frame Building

Due to our expertise in custom design, manufacturing, and installation of light steel frame buildings and other styles of steel structure buildings, we have earned inevitable reputation among our customers. As a reputed designer and manufacturer of light steel frame houses, we can also manufacture all the components needed for steel frame home construction, in-house.

Installation of Light Steel Frame Building

As all the components have been manufactured in our workshops, and thus this light steel frame building is quite easy to assemble and install. Its construction requires less labor costs and time, quite efficient and economical. Usually, a 300m2 steel framed house could be installed by eight workers in only two months despite weathers (all-weather construction). Moreover, thanks to its convenient installation, customers could create the district environment before the installation of the steel building.

General Description

Light steel frame building provided by DONGYE, as its name suggests, is a reliable prefabricated metal building that adopts light steel framing. It is distinguished from other steel structure buildings by its light weight, great mechanical endurance, excellent thermal insulation, energy efficiency and etc.

Features of Light Steel Frame Building

1. Energy Conservation

This steel building manufactured by DONGYE is made of latest energy-saving and heat-insulation materials which forms a reliable protective system to effectively avoid “thermal bridge”(also called cold bridge). Therefore, this light steel frame building enjoys a much better heat insulation performance and ensures a cozy inside living environment for users. Especially, even when it is 0ºC outdoors, the indoor temperature could be above 17ºC. Similarly, when outdoor temperature reaches 30ºC, the indoor is still about 21ºC.

Obviously, this light steel frame building could significantly reduce the usage of container and consumption of electricity (over 30%), helping you save spendings. Moreover, the construction of this light steel frame home consumes 30% less energy compared with the traditional buildings.

2. Environment Friendliness

Compared with the traditional buildings, this light steel frame building, adopting dry construction, requires far less water in the construction. Its steel frame is 100% recyclable and other parts 80% recyclable, significantly reducing wastes and pollution of the environment. Meanwhile, its CO2 emission is only 1/3 of the traditional building’s.

3. Land Conservation

Wall thickness of this light steel frame building is only half of that of the concrete buildings. Therefore, this house enjoys a high efficiency rate—92%, 10% higher than that of the traditional concrete buildings. Meanwhile, it allows users to allocate the inner space in a more flexible way.

4. Fireproof-ness

As this light steel frame building is equipped with fire-proof plaster plates, it is highly resistant to fire. To be more specific, the common walls of this light steel frame house are equipped with 25.4mm plaster plates to ensure a one-hour fire-resistance performance. Between the walls, pillars and floor joists are stuffed with quality class fibers which are thermally insulated and fire-proof.

Noiseproof-ness

As we have mentioned above, walls and floor joists of this pre-engineered steel house are filled with class fibers that could effectively mitigate the transmission of sound through air. Therefore, it is highly noise-proof. Moreover, this metal frame house is further strengthened by a unique measure that could significantly reduce the transmission of solid borne noise.

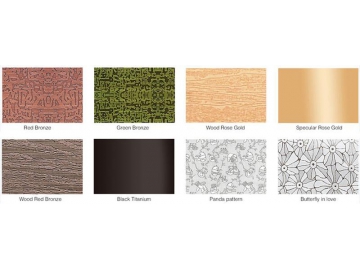

| Type | C-shape and U-shape section |

| Cross Section | 75mm,89mm,120,140mm,200mm,250mm |

| Thickness | 0.7mm to 2mm(24g-14g) |

| Material | Q345,G550 |

| Surface Treatment | Galvanization, Aluminum-zinc galvanization |

Please note that: our automatic production line could process six types of C-shape and U-shape sections. Every day, it could manufacture all components needed by a 60Om2 steel frame home.