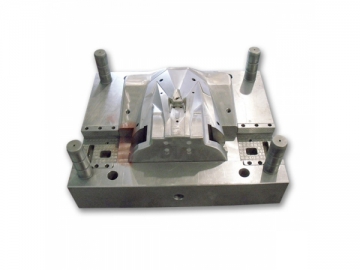

Mold Design

We have designed hundreds of plastic injection molds and die casting molds over the past years. Having capacity and experience, we can always accurately and efficiently supply you with basic or complex mold design services, from the design of plastic injection molds, through die casting molds, metal stamping molds, to rubber compression molds.

Our design of manufacturability ensures the molding to make high quality parts all the time, consistently meeting customers’ highest expectations. Having professional industry knowledge of mold design and mold manufacturing, we are eligible for offering the most effective molds and molded products with the most favorable price. We can efficiently work out your mold design with low maintenance and long lifespan.

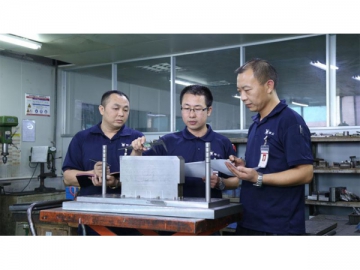

Our experts are ready to provide you with technical support to optimize the mold design and mold manufacturability at the lowest cost. We carefully study the drawing and apply the technologies of Pro-E, Solid Works, UG and CAD to design the mold and molded parts. It not only avoids any mistakes, but also ensures our good technical communication with customers.

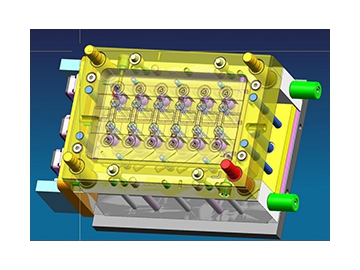

We offer extended service of 3D mold design, from the simple division of the parting line to the accomplishment of the full 3D mold. Our 3D mold design includes all the parting lines, fillets and drafts. In order to guarantee the precision and accuracy, our engineers will apply the 3D modeling technique and other most advanced technology to work out your required mold with you.

The following is a partial list of our mold steels and mold components currently in use:

718, 718H, S136, S136H, 420ESR from ASSAB of Sweden.

P20, P20 S, P20 Ni, 420, H13, 01 from LKM.

NAK80 from DAIDO of Japan.

Most mold bases and standard components come from LKM, DME and HASCO.

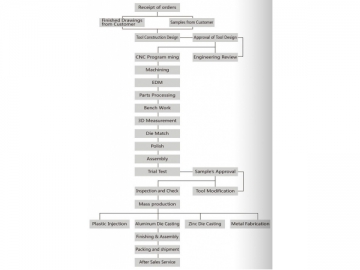

| Advantage | In-house mold design and mold manufacturing Precision single-cavity and multi-cavity molds Design for manufacturability Fast turnaround |

| Flow Chart | 1. Drawing design |

| 2. Drawing discussion | |

| 3. Mock-up assembly testing | |

| 4. Mold structure design | |

| 5. Mechanism confirmation | |

| 6. Processing | |

| 7. Mold assembly testing | |

| 8. Sample examination | |

| 9. Mold modification | |

| 10. Quality confirmation | |

| 11. Delivery |

| Name | Quantity | Place of Origin |

| CNC Machine Center | 5 | Taiwan/ Japan |

| EDM( Electric Discharge Machine) | 6 | China |

| Mirror Finish EDM | 1 | Japan |

| Wire Cutting | 5 | Taiwan |

| Grinding Machine | 3 | China |

| Milling Machine | 10 | China |

| Drilling Machine | 15 | China |