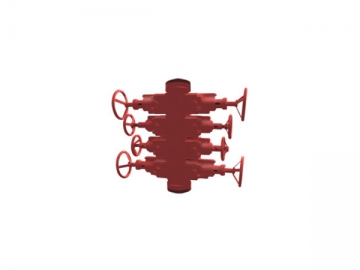

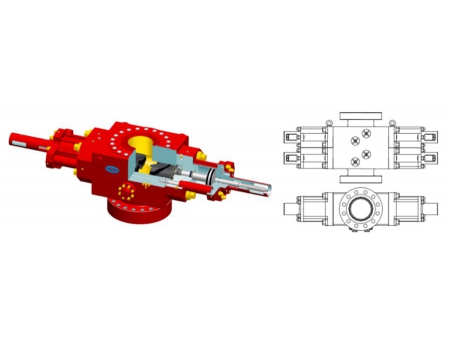

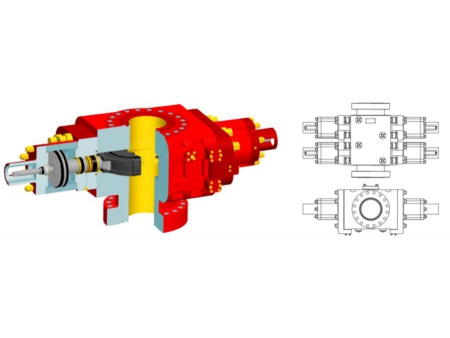

Coiled Tubing BOP

The pressure-bearing element such as the housing for the coiled tubing BOP is produced from forge piece featuring excellent strength and impact toughness. The oilfield blowout preventer is installed with blind ram, shear ram, and semi-blind ram in sequence from top to bottom. The mentioned rams are designed with round chamber, for optimal processibility, small stress concentration, and light machine weight.

1. The elastomeric seal of the ram for the coiled tubing BOP has big reserve and reliable sealing performance.

2. Two balancing valves are installed on blind chamber and the semi-blind chamber, to balance the pressure before the blind ram and the pipe ram are opened. So, the operational safety of the petroleum drilling equipment is guaranteed.

3. For convenient operation, high reliability and high safety, the oil circuit for the switch is installed with quick connector. In addition, two side boards are installed on the coiled tubing BOP to prevent the quick connector from being damaged.

4. Apart from the hydraulic control device, the ram is engineered with manual locking device to ensure the high operational safety in case there is hydraulic oil loss.

5. The full sealing and semi-sealing of the oil well control device can be realized manually under the circumstance that the check valve of the oil cylinder is opened.

| Diameter | 79.4mm (3 1/8") |

| Hydraulic Cylinder Diameter | 100mm |

| Rated Working Pressure | 35MPa (500psi) |

| Hydrostatic Testing Pressure | 52.5MPa (7500psi) |

| Rated Working Pressure of Hydraulic Control System | 21MPa (3000psi) |

| Recommended Working Pressure of Hydraulic Control System | 8.4MPa-10.5MPa (1200psi~1500psi) |

| Temperature Grade | T20 (-29℃~ -121℃) |

| Machine Weight | 830kg |