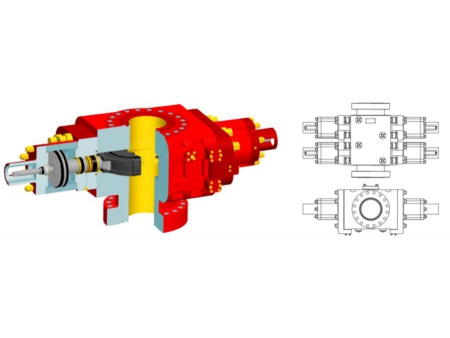

Coiled Tubing BOP (Blowout Preventer)

Request a Quote

- Quad Blowout Preventer

Stripper Assembly

Stripper Assembly

A coiled tubing BOP is a key part of a well control system. The tubing BOP is often used to control the wellbore pressure in drilling processes like well testing and repairing, in order to effectively prevent blowout accidents and create a safe working environment.

A coiled tubing blowout preventer comprises two parts, the quad blowout preventer and the stripper assembly. Both are designed, produced and tested in accordance with standards of API Spec 16A and API RP 5C7. The BOP interior surface also meets the requirements of NACE MR0175 to be H2S resistant.

Stripper Assembly

| Model | Bore Size | Rated Working Pressure | Maximum Pressure for Packing Hydraulic Control System | Intensive Working Pressure of the Packing Hydraulic Control System | Maximum Pressure for Round Window Hydraulic Control System | Intensive pressure of the Round-window Hydraulic Control System | Oil Consumption to Open | Oil Consumption to Close | Temperature Rating | Matching Packing | Top Connection | Bottom Connection | Overall Dimension H | Weight | |

FPH6.5-70 | 65mm 29/16" | 70 MPa 10.000 psi | 21 MPa 3,000 psi | 31.5 MPa 4,500 psi | 10 MPa 1,450 psi | 31.5 MPa 4,500 psi | 0.7 L 0.18 gal | 2L 0.53 gal | T20 (-29~1219℃) | 1”1 1/4, 1 1/2”packing | 4.75-4-ACME Male union | 2.9/16”-10,000 psi Flange connection | 1190 mm 46.85” | 235 kg 518Ib | |

FPH6.5-35 | 65mm 29/16" | 35 MPa 5000 psi | 21 MPa 3000 psi | 31.5 MPa 4500 psi | 10 MPa 1450 psi | 31.5 MPa 4500 psi | 0.7 L 0.18 gal | 2L 0.53 gal | T20 (-29~121℃) | 1”,11/4, 1 1/2”packing | 4.75-4-ACME Female union | 4.75-4-ACME Female union | 892 mm 35.12" | 182 kg 401 Ib | |

Quad Blowout Preventer

| Model | Bore Size | Rated Working Pressure | Rated Working Pressure of the Hydraulic Control System | Recommended Hydraulic Operating Pressure | Oil Consumption to Open | Oil Consumption to Close | Body Side Outlet | Temperature Rating | Matching Packing | Top Connection | Bottom Packing | Overall Dimension H | Weight |

4FZ6.5-70 | 65 mm 2 9/16" | 70 MPa 10000 psi | 21 MPa 3000 psi | 8.4~10.5 MPa 1,200~1,500 psi | 1.5L 0.40 gal | 1L 0.26 gal | 21/16"-10,000 psi | T20 (-29~121℃) | C.S.O. SBR. Slip Ram (1",13/4"), 1 1/2",1 1/4", 1 3/4" | 2.9/16'-10,000 psi Studding connection | 2.9/16"-10,000 psi Flange Connection | 930mm 36.61" | 1020 kg 2249 lb |

| 65 mm 2 9/16" | 70 MPa 10000 psi | 21 MPa 3000 psi | 8.4~10.5 MPa 1,200~1,500 psi | 1.5L 0.40 gal | 1L 0.26 gal | 21/16"-10,000 psi | T20 (-29~121℃) | 6.312-4-ACME Union connection | 29/16"-10,000 psi Flange Connection | 950 mm 37.40" | 1107 kg 2441Ib | ||

4FZ6.5-35 | 65 mm 2 9/16" | 35 MPa 5000 psi | 21 MPa 3000 psi | 8.4~10.5 MPa 1,200~1,50 | 1.5L 0.40 gal | 1L 0.26 gal | 21/16"-5,000 psi | T20 (-29~121℃) | 1.9",1.66",23/8" | 4.75-4-ACME Male union | 4.75-4-ACME Female union | 550 mm 21.65" | 956 kg 2108 Ib |

4FZ13-70 | 130 mm 5 1/8" | 70 MPa 10000 psi | 21 MPa 3000 psi | 8.4~10.5 MPa 1,200~1,500 psi | 3.3L 0.87 gal | 3.6L 0.95 gal | 21/16"-10,000 psi | T20 (-29~121℃) | C.S.O. SBR. Slip Ram 2",2 3/8" | 51/8"-10,000 psi Flange Connection | 5.1/8"-10,000 psi Flange Connection | 1476 mm 58.1" | 2766 kg 6098 Ib |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos